Arc heating method and device

An electric arc heating and electric arc technology, which is applied in the direction of electric heating devices, heating by discharge, electrical components, etc., can solve the problems of shortened service life of the heated body, damage of high-energy arc heating, and damage of the substrate, so as to achieve the effect of ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

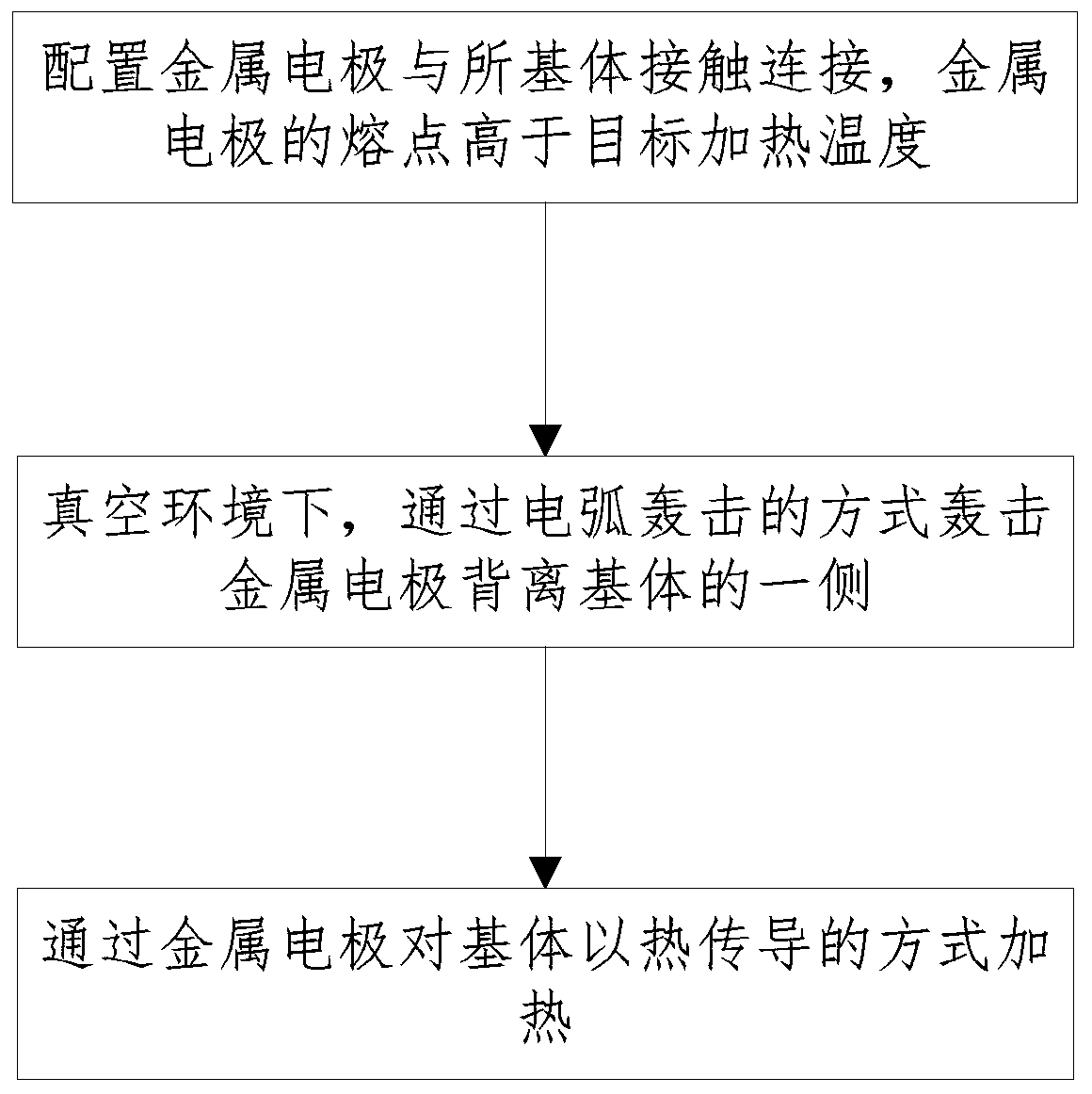

[0040] The embodiment of the present application provides an arc heating method, which is suitable for heating a matrix formed by direct pressing of powder, a matrix formed by direct sintering of powder, or a product formed by pressing and sintering of powder, such as figure 1 As shown, the arc heating method includes the following steps: firstly, the metal electrode is configured to be in contact with the substrate, and the melting point of the metal electrode is configured to be higher than the target heating temperature; then, in a vacuum environment, bombard the metal electrode away from the substrate by means of arc bombardment One side is used to heat the metal electrode; finally, the substrate is heated by heat conduction through the metal electrode heated by the arc. Metal electrodes have the properties of high density and high temperature resistance, so under the bombardment of high current, the metal electrodes will not be cracked and damaged, and the high temperature...

Embodiment 2

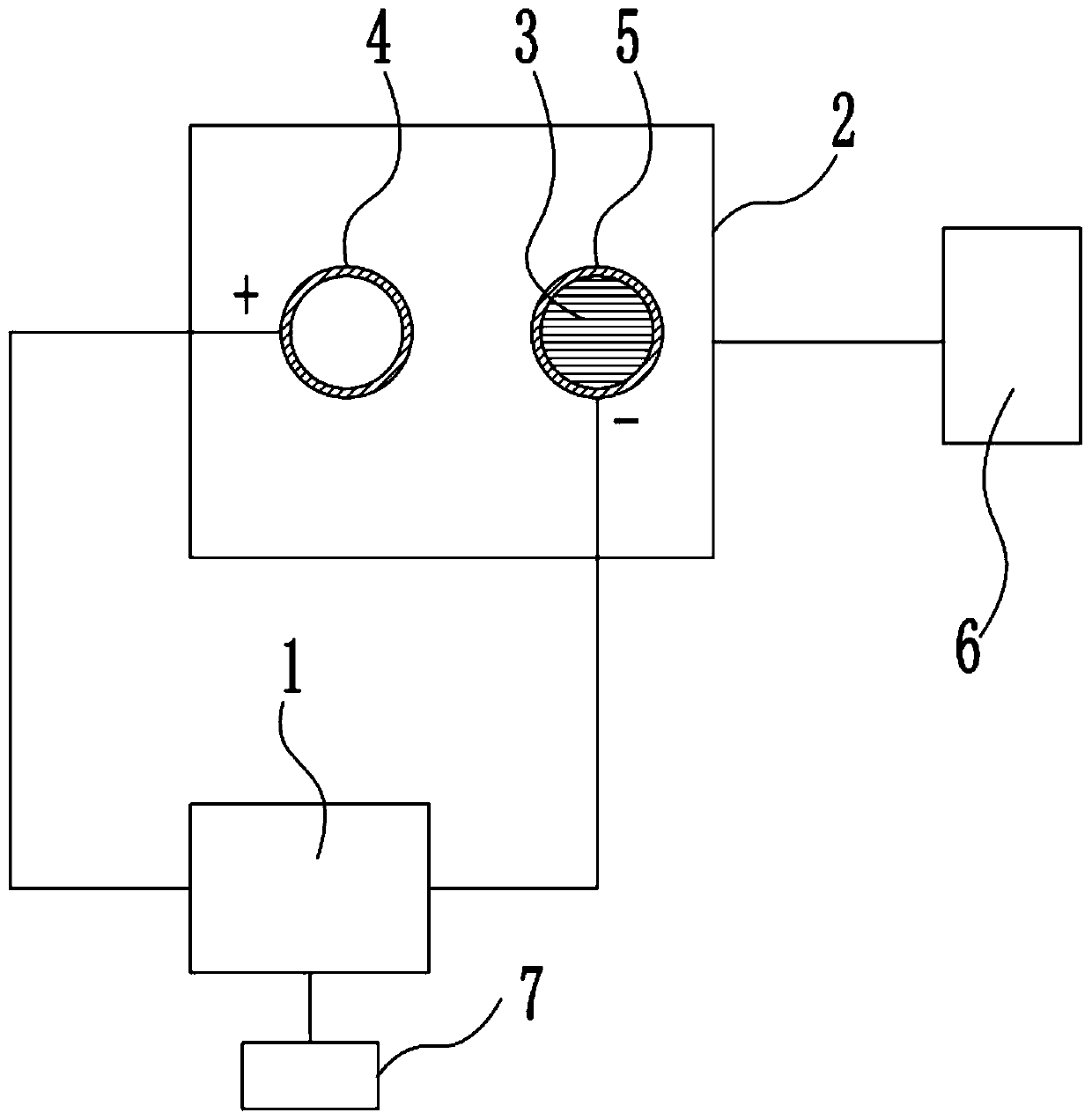

[0048] In order to realize the arc heating method for heating the matrix formed by powder pressing and / or sintering provided in Example 1, the embodiment of the present application provides an arc heating device for heating the matrix formed by pressing and / or sintering powder matrix.

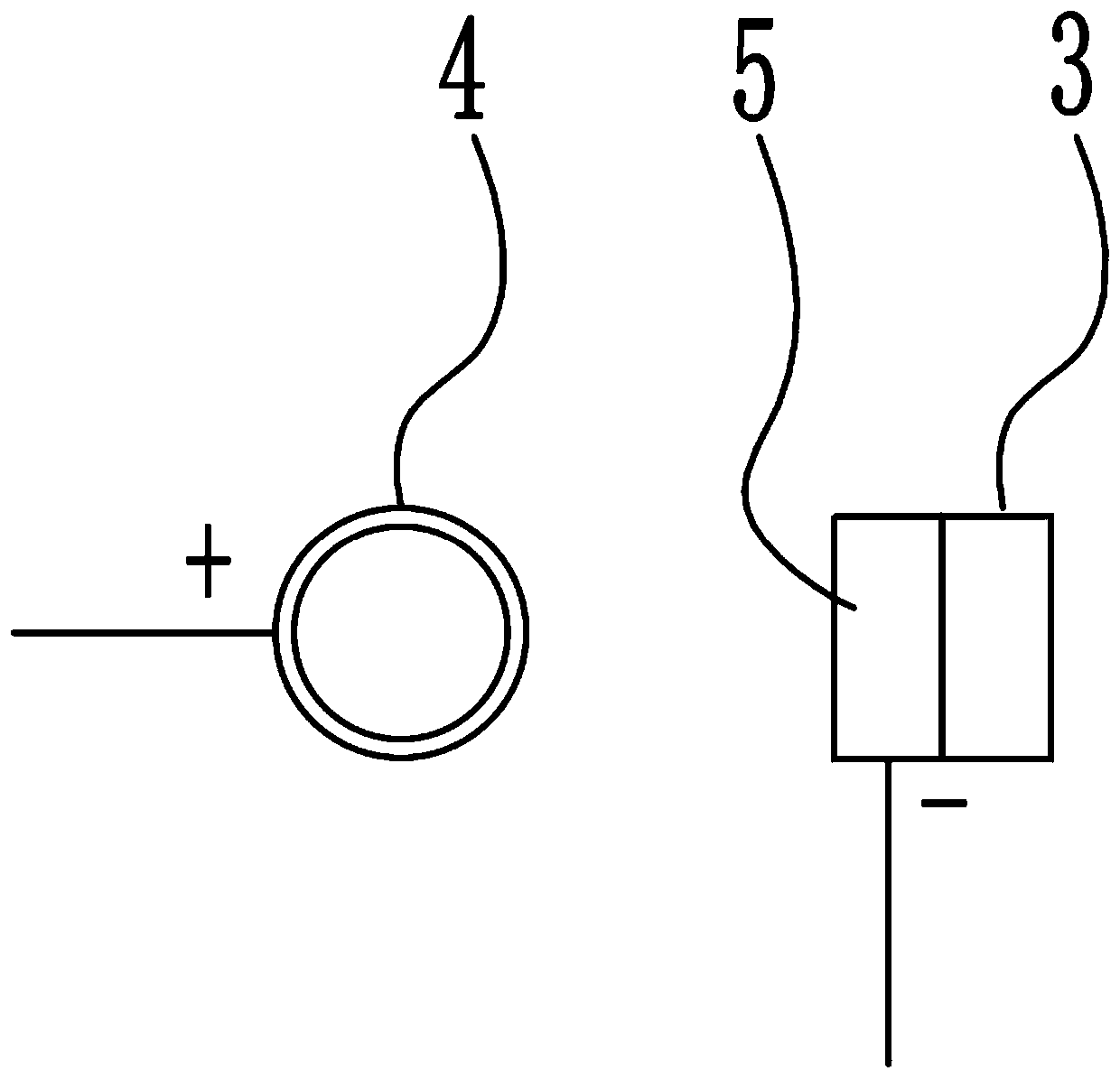

[0049] Such as figure 2 As shown, the arc heating device includes an arc generator 1, a vacuum chamber 2 and a substrate 3, the substrate 3 and the positive and negative electrodes of the arc generator 1 are located in the vacuum chamber 2, and the materials of the anode 4 and the cathode 5 of the arc generator 1 are both It is metal, the cathode 5 is configured to provide thermal energy to the base 3 in a heat conduction manner, and the anode is arranged on the side of the cathode 5 away from the base 3 . The specific working process of the arc heating device provided by the above-mentioned embodiment can be as follows: vacuumize the vacuum chamber 2 to keep it at a certain degree of vacuum,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com