Filtering and dispersing device

A dispersing device and filtering device technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of reactor space occupation, production impact, stuck pump outage, etc., to improve the mixing effect and strengthen the stirring effect, to avoid the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

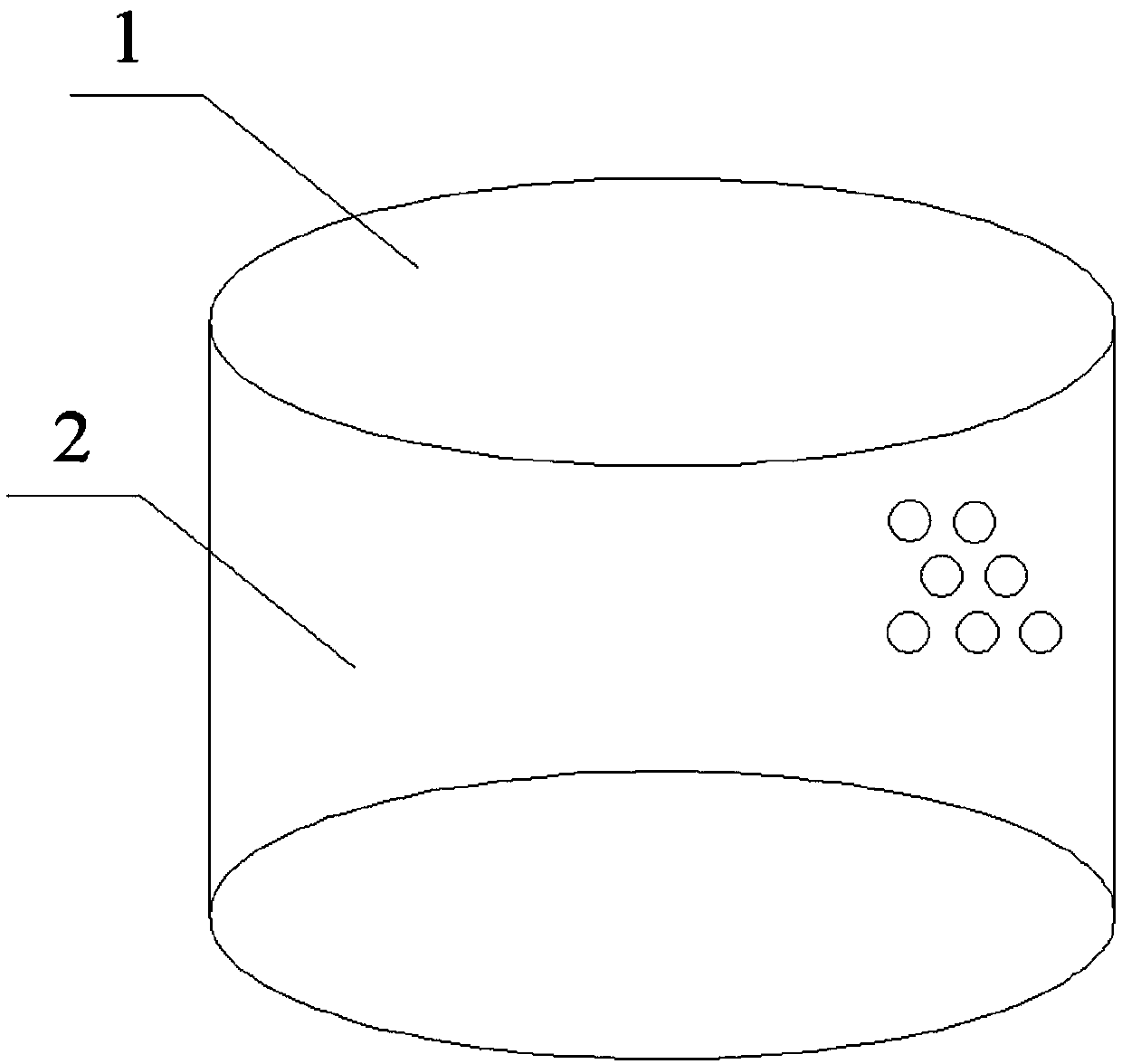

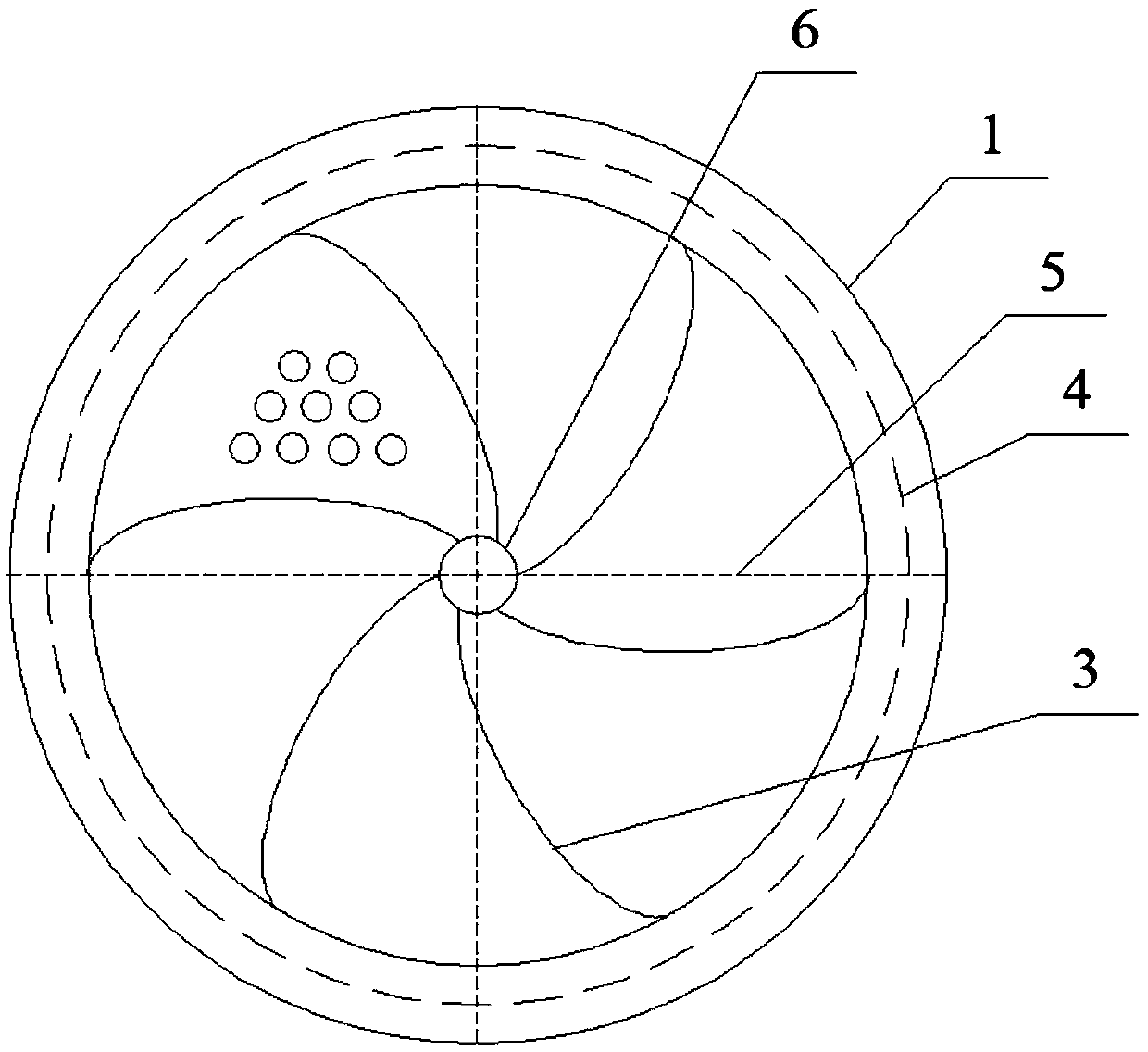

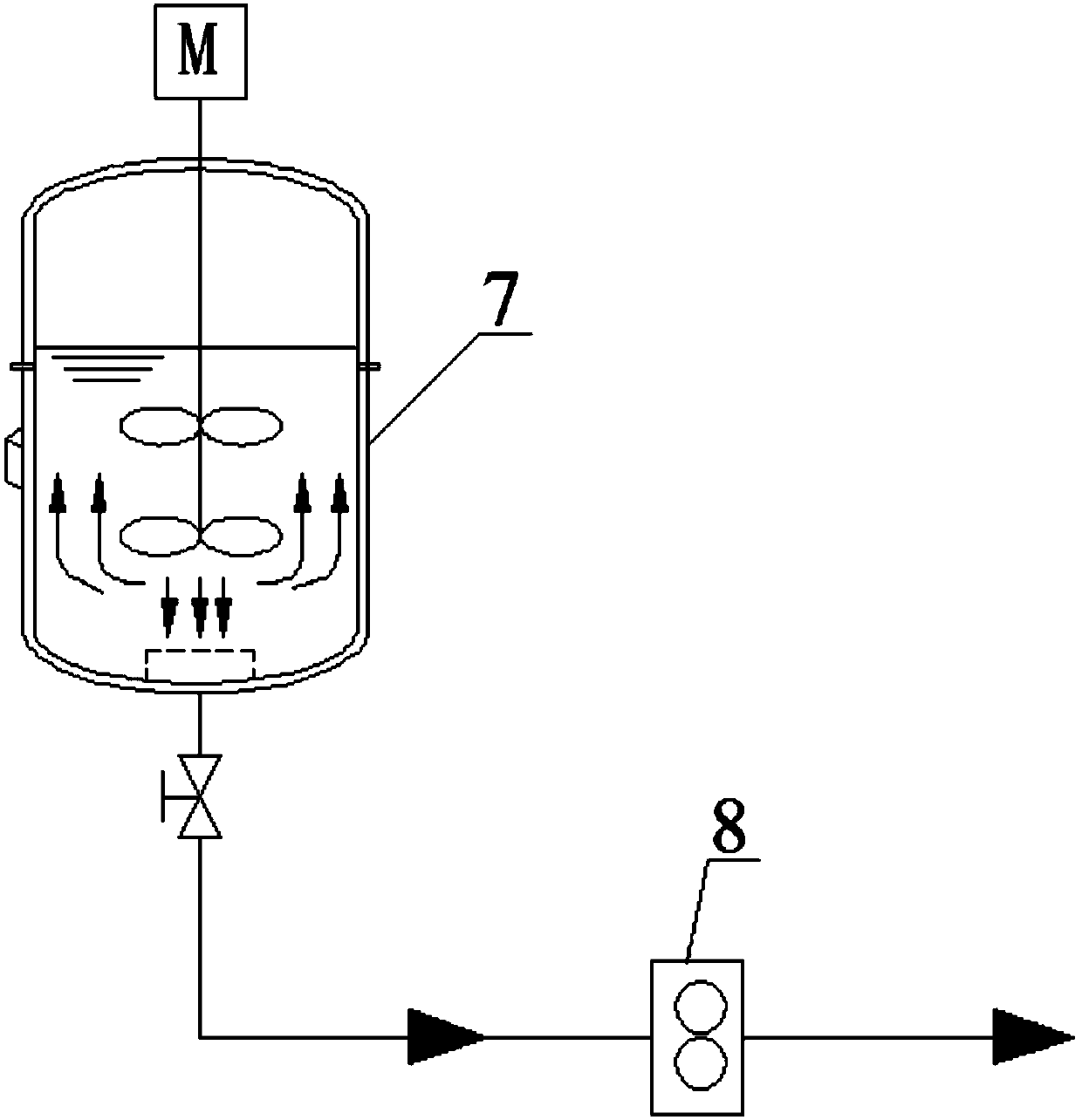

[0023] like Figure 1-Figure 2 As shown, a filter dispersing device, the dispersing filter device is an inverted basket filter, comprising a top circular filter screen 1, a hollow cylindrical filter screen 2, the circular filter screen 1 passes through the It is made by opening holes in a circular steel plate with a diameter of 495 mm. A central hole 6 with a diameter of 50 mm is provided at the center of the circular filter screen, and filter holes with a diameter of 10 mm are evenly distributed at the non-center position. The circular filter screen The opening ratio of the cylindrical filter is 58%; the height of the cylindrical filter is 160mm, and the diameter of the filter hole of the cylindrical filter is 10mm, and the opening of the cylindrical filter is 58%; the cylindrical filter The upper end of the net 2 is welded and fixed with the circular filter net 1, and the inner wall of the lower end of the cylindrical filter net 2 is welded with a support ring 4, and the cyl...

Embodiment 2

[0027] A kind of filter dispersing device, the structure is the same as embodiment 1, the diameter of adjusting circular steel plate is 100mm, the central hole diameter of circular filter screen is 20mm, the filter hole diameter at the non-center position of circular filter screen is 5mm, circular filter screen The opening rate of the net is 58%; the height of the cylindrical filter is 150mm, the diameter of the filter hole of the cylindrical filter is 5mm, and the opening rate of the cylindrical filter is 58%; the height of the arc baffle is 100mm .

[0028] The lower end of the filter dispersing device of this embodiment is then welded and fixed on the inner wall around the outlet of the PTA slurry preparation tank; after implementing the present invention, the plugging phenomenon of the slurry preheater on the outlet pipeline disappears, and the PTA content index of the slurry Significantly more stable, improving the intrinsic quality of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap