Fixed building reinforcement cutting machine

A technology for building steel bars and cutting machines, which is applied in the directions of grinding machine parts, grinding workpiece supports, grinding machines, etc., can solve the problems of labor and injury of construction workers, and achieve the effect of high safety and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

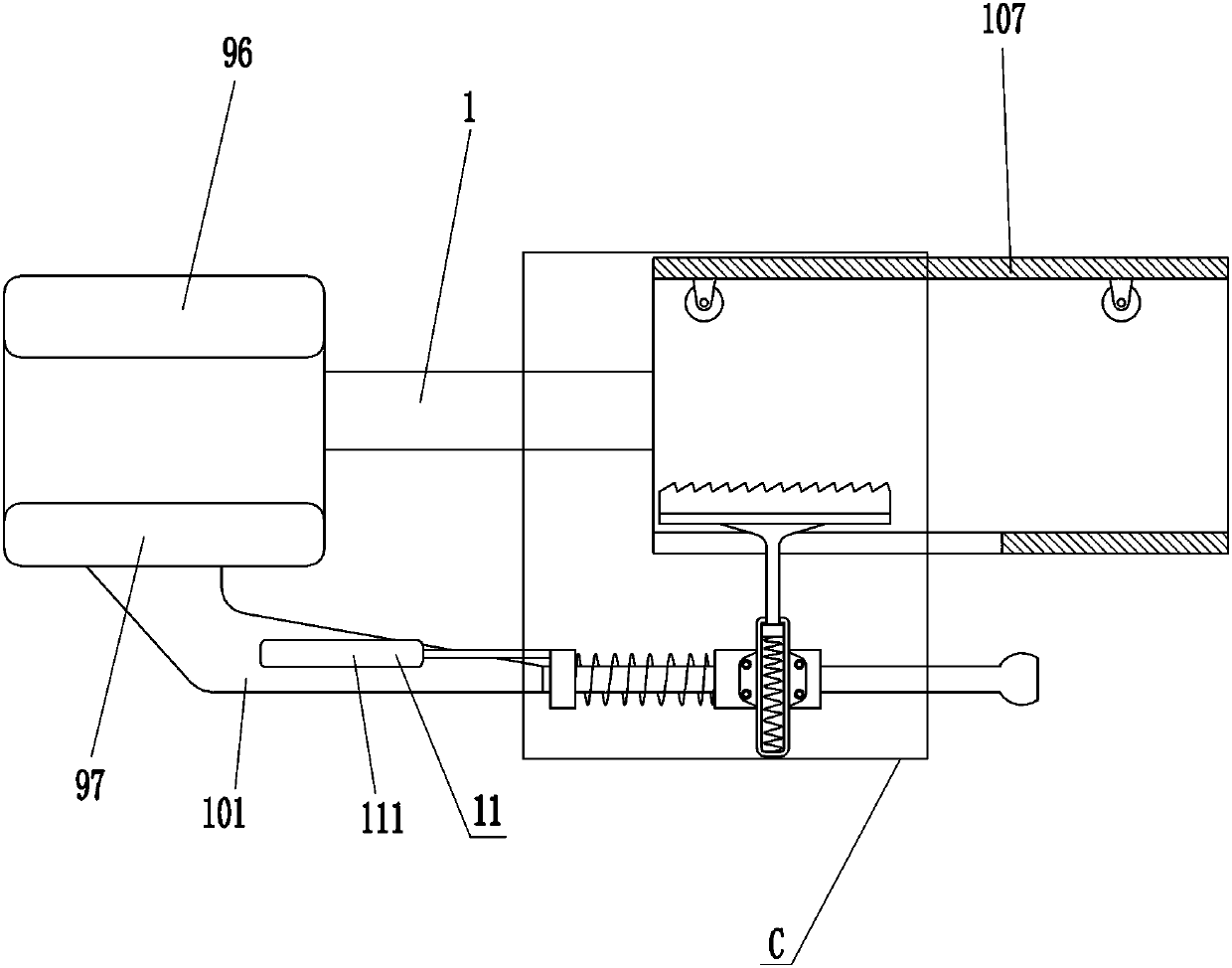

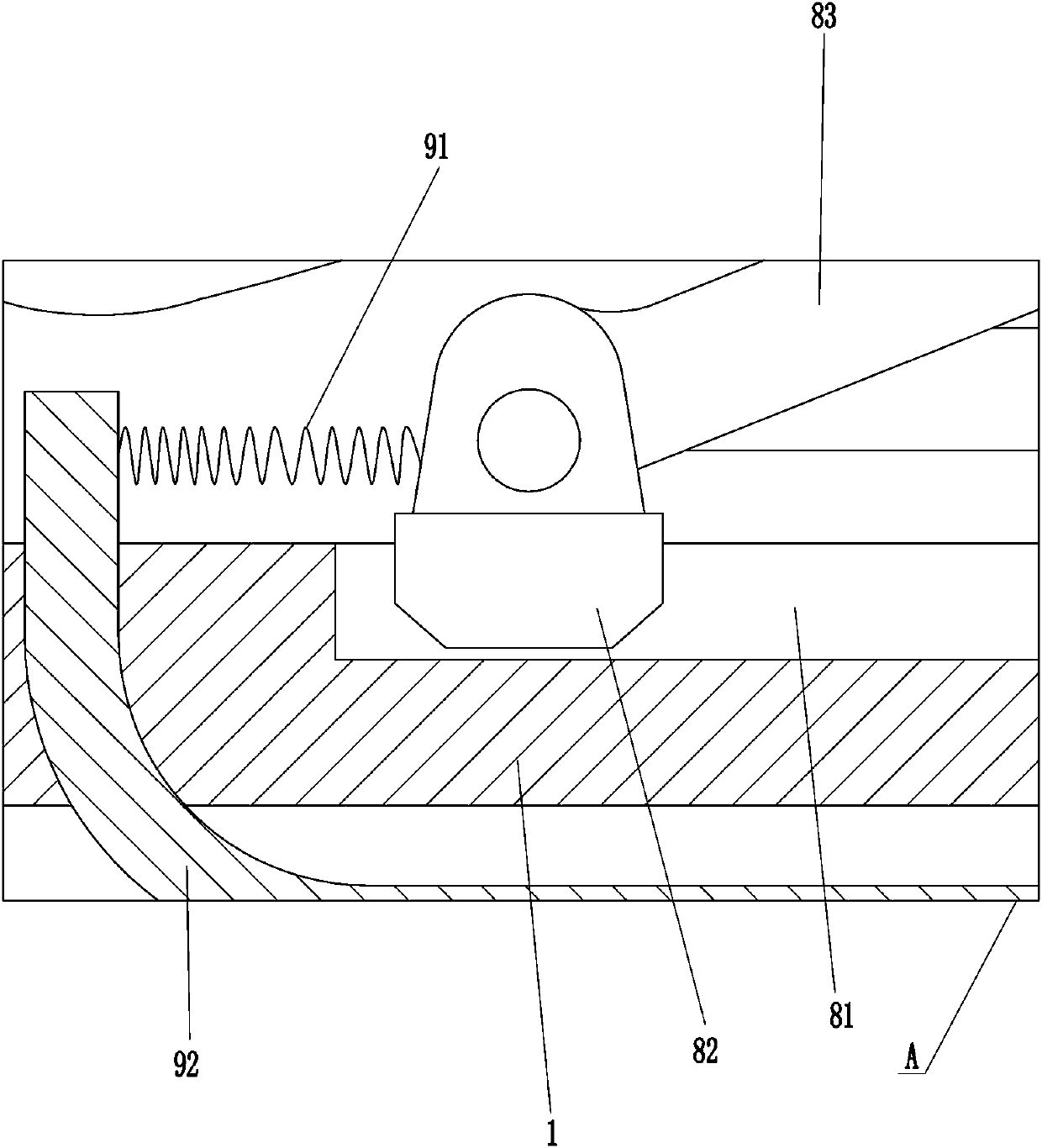

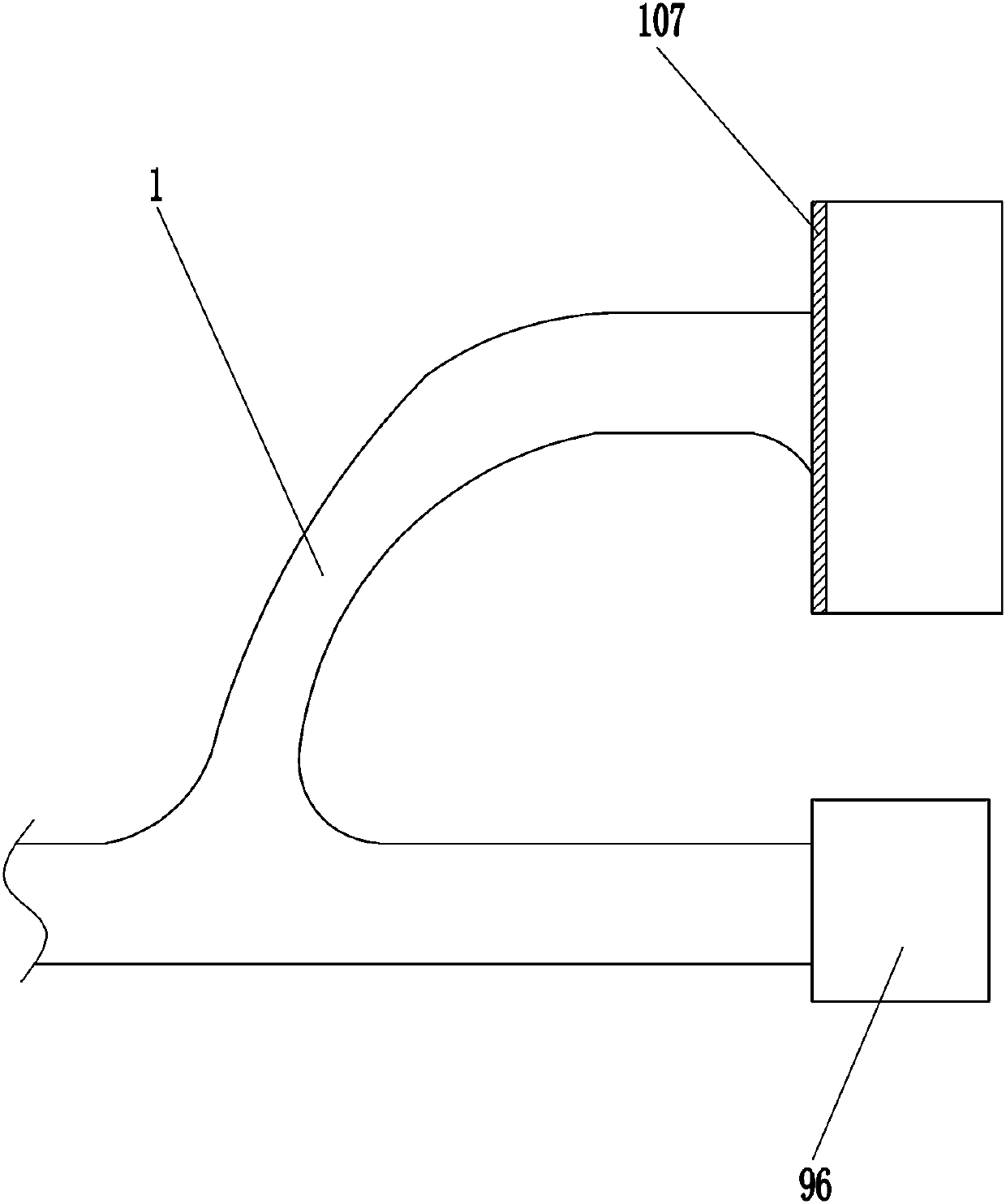

[0027] A kind of fixed building reinforcement cutting machine, refer to figure 1 and Figure 6 , including a mounting frame 1, an arc beam 2, a first handle 3, a second handle 6, a cutting device 8 and a fixing device 9, the left side of the mounting frame 1 is connected with an arc beam 2, and the left part of the arc beam 2 is fixedly connected There is a first handle 3, a second handle 6 is connected to the rear side of the mounting frame 1, a cutting device 8 is provided on the top of the mounting frame 1, and the cutting device 8 is used to cut steel bars, and a fixing device 9 is provided at the bottom of the mounting frame 1. 9 is used for clamping reinforcing bar.

[0028] refer to figure 1 , Figure 8 and Figure 9 , also includes a control module, a pause key 4 and a start key 5, the top of the arc-shaped beam 2 is provided with a pause key 4, and the front side of the arc-shaped beam 2 is provided with a start key 5, and both the pause key 4 and the start key 5 ...

Embodiment approach 2

[0035] On the basis of Embodiment 1, refer to Figure 4 , Figure 5 and Figure 7 , also includes an anti-drop device 10, the anti-drop device 10 includes a fixed plate 101, a slide bar 102, a first sliding sleeve 103, a sleeve 104, a second spring 105, a friction plate 106, a gap ring 107 and a sleeve Rod 108, notch ring 107 is installed on the right side of mounting frame 1, and notch ring 107 is positioned at the rear side of first pressing plate 96, and the bottom of second pressing plate 97 is connected with fixed plate 101, and the rear side of fixed plate 101 is equipped with the slide that plays guiding role. Rod 102, fixed plate 101 is connected with slide bar 102 by the mode of bolt connection, slide bar 102 is provided with the first sliding sleeve 103, and sleeve 104 is installed on the first sliding sleeve 103, and first sliding sleeve 103 is passed through bolt The connection mode is connected with the sleeve 104, the sleeve 104 is provided with a sleeve rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com