HST control mechanism and agricultural machinery

A control mechanism and driving mechanism technology, applied in the layout of power plant control mechanism, mechanical equipment, control device and other directions, can solve problems such as poor directional stability, improve directional stability, reduce labor intensity, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

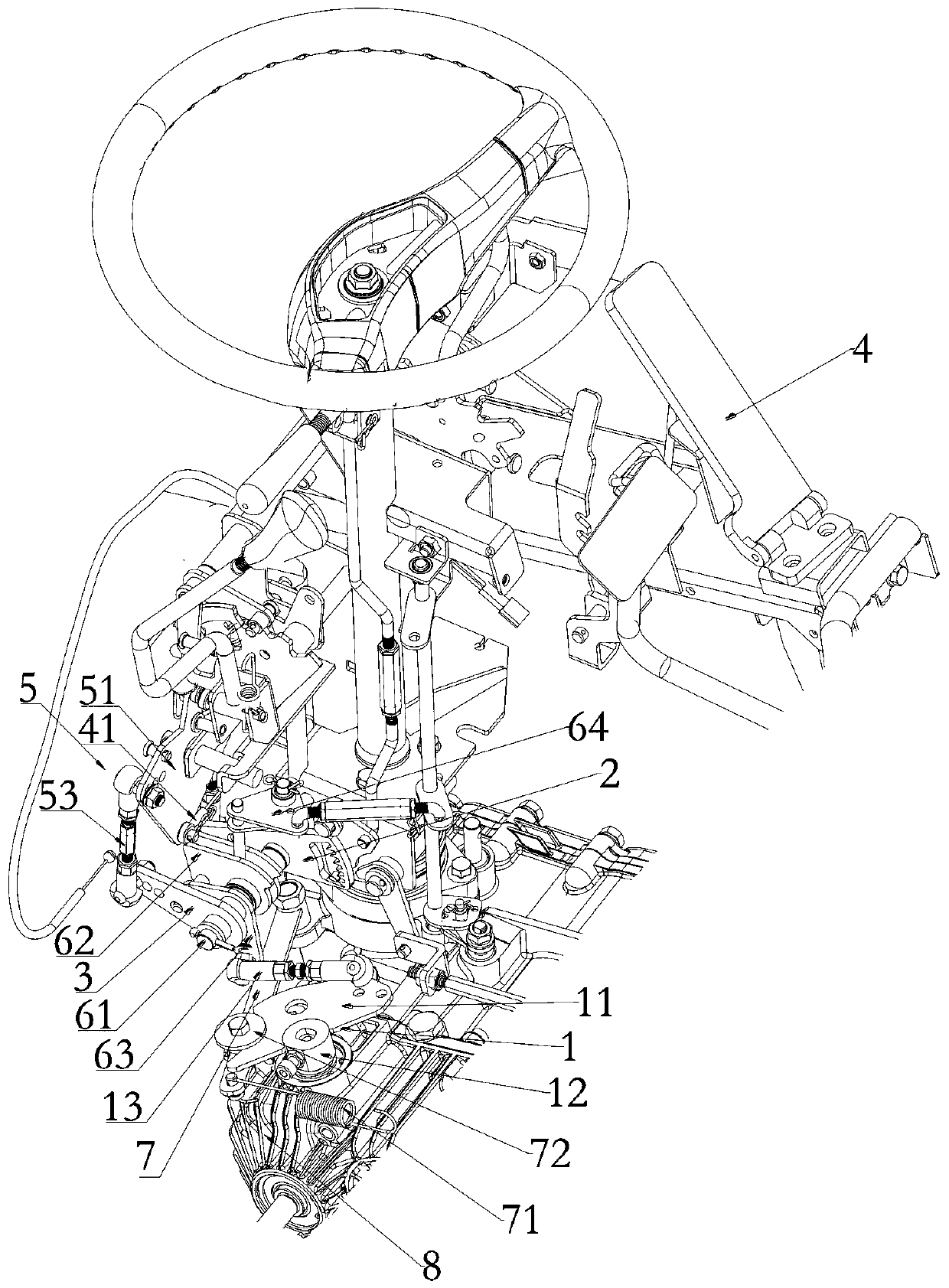

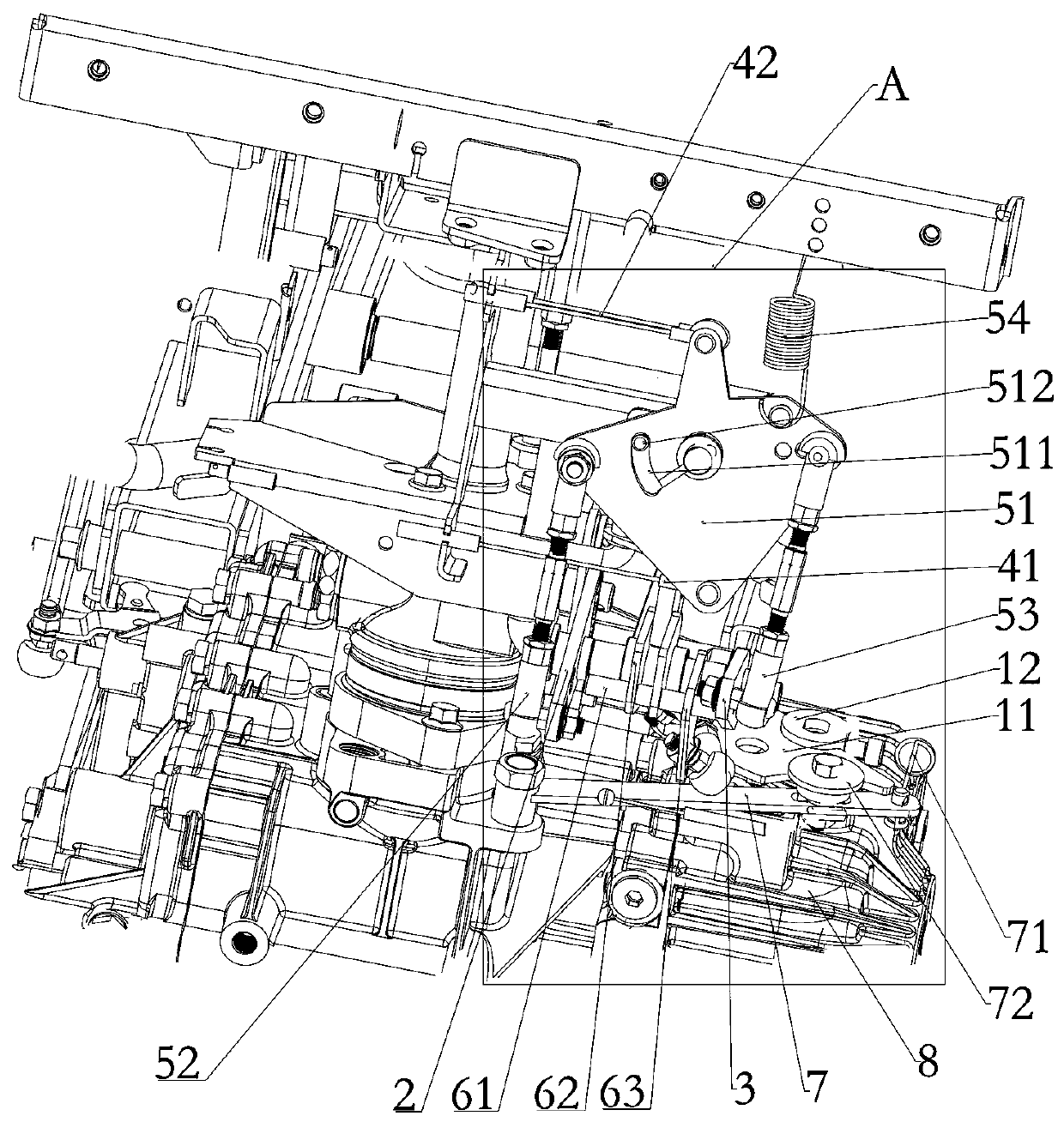

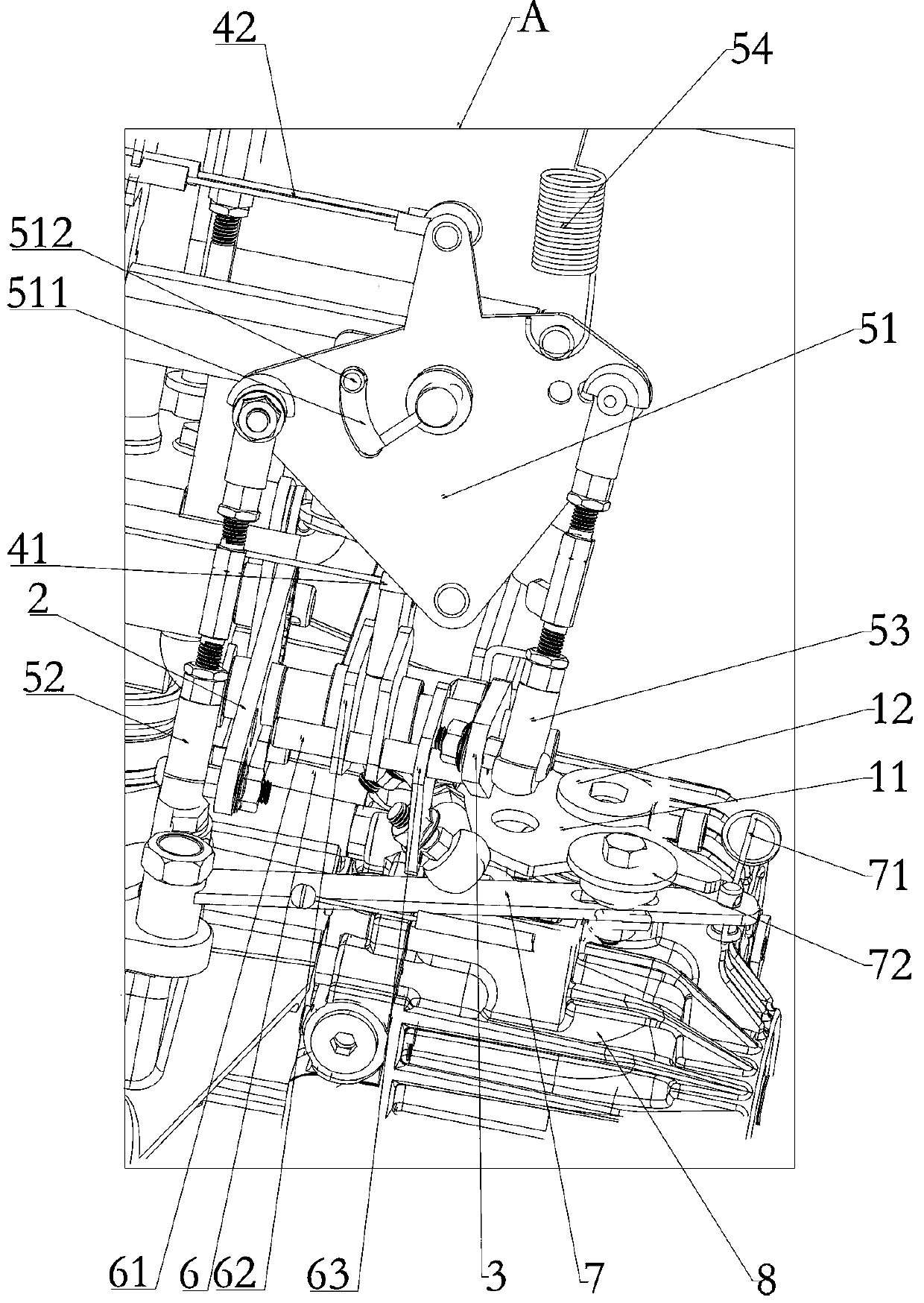

[0037] Such as Figure 1-Figure 3 As shown, an HST control mechanism of this embodiment includes an HST displacement adjusting member 1, a shift mechanism 6, a forward end swing arm 2, a backward end swing arm 3, and a drive mechanism 5, which is hinged on the machine On the frame, the power end of the drive mechanism 5 is connected to the foot throttle 4 through the foot throttle cable 41, the drive end of the drive mechanism 5 is connected to the engine through the engine throttle cable 42, and the drive ends of the drive mechanism 5 are connected to the engine respectively. Connected with the forward end swing arm 2 and the backward end swing arm 3, the forward end swing arm 2 and the backward end swing arm 3 are respectively connected to the shift mechanism 6 and realize the forward mode and the reverse mode through the shift mechanism 6 Switch, the shifting mechanism 6 is connected to the HST displacement adjusting member 1; wherein, in the forward mode or the reverse mode...

Embodiment 2

[0052] An agricultural machine of this embodiment includes an engine, an HST 8 and the HST control mechanism, and the HST displacement adjusting member 1 is installed on the HST 8 for adjusting displacement. The agricultural machinery of this embodiment can ensure that the steering wheel is held with both hands when increasing and decelerating, reducing the "S" shape of the working route, improving directional stability, without frequent operation of the handle bar, high comfort, and greatly reducing the driver’s labor intensity. When climbing hills, crossing bridges and getting on trucks, the steering wheel is operated with both hands, which is safe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com