Efficient aerated concrete block production line mold brushing all-in-one machine and brushing process

A kind of aerated concrete and production line technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of poor controllability and adaptability, easy accumulation at the bottom, strong limitations, etc., and achieve enhanced controllability and adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

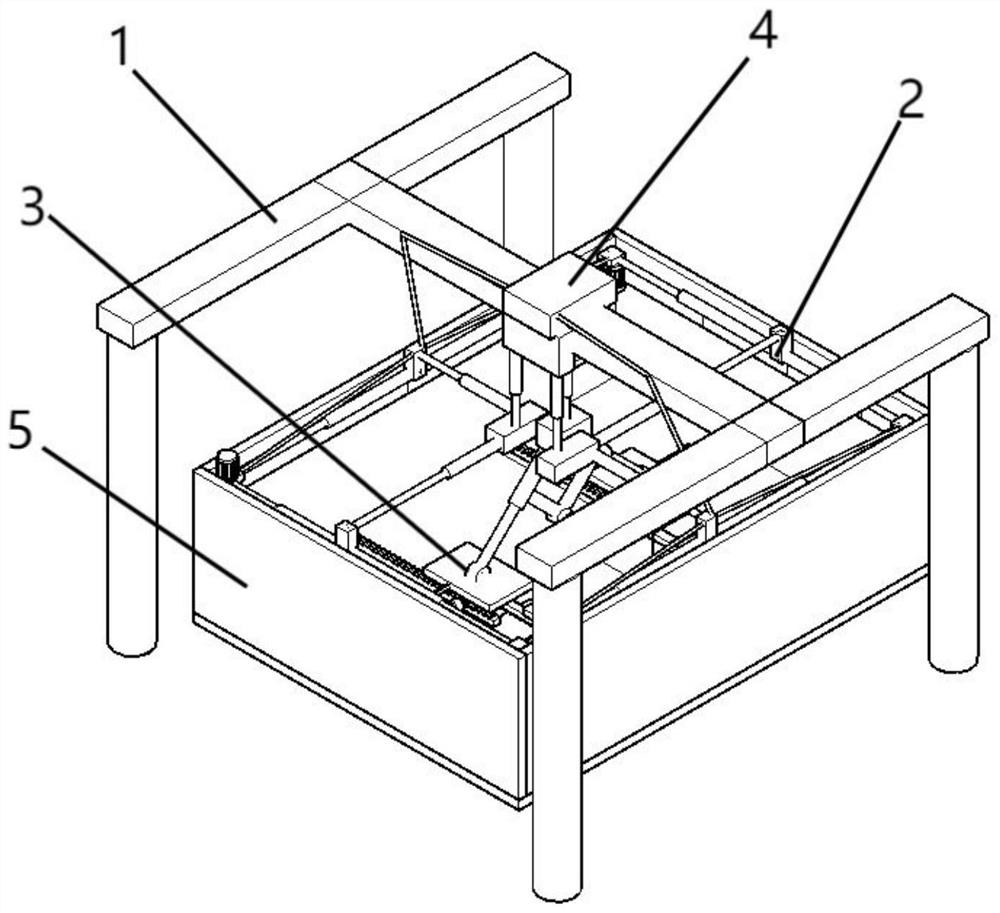

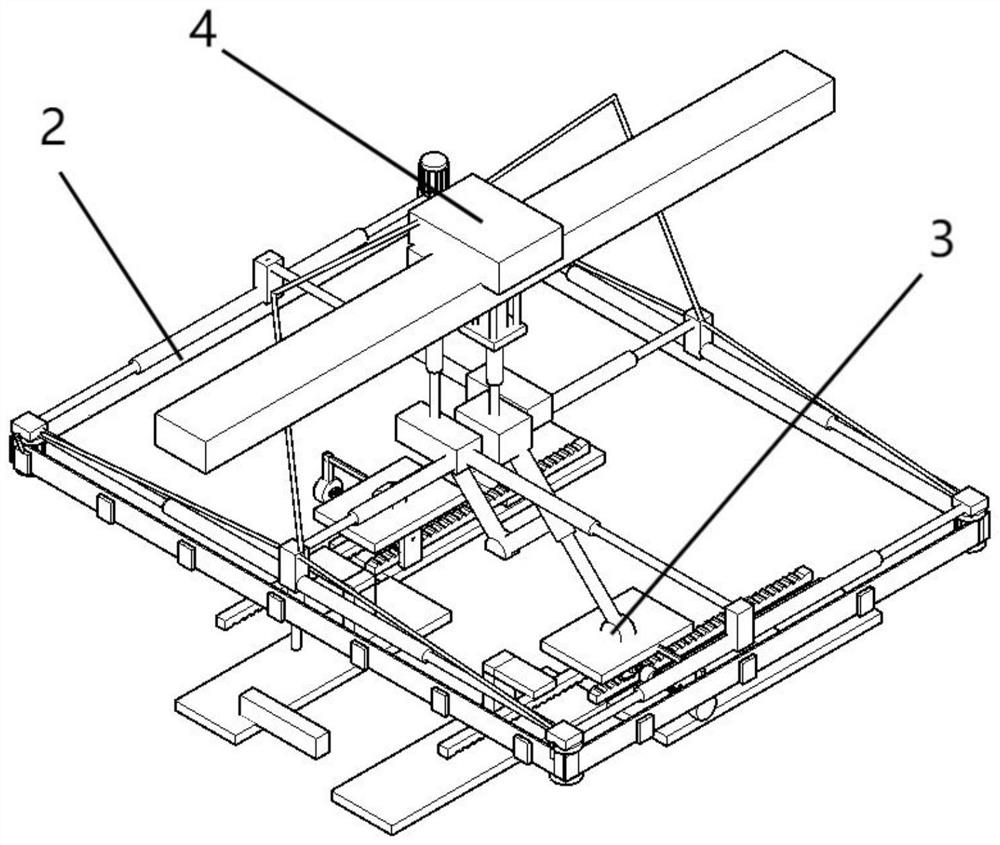

[0032] Example 1: High-efficiency aerated concrete block production line mold painting integrated machine, such as figure 1 and figure 2 As shown, it includes: bracket 1, side smearing device 2, bottom surface smearing device 3, liquid supply device 4, mold 5; bracket 1 is fixedly installed on the transfer path of casting mold 5; side smearing device 2 and bottom surface smearing device 3 are arranged on On the bracket 1, the two devices can be driven by their own cylinder mechanism and extend into the casting mold 5 to apply the release agent; the liquid supply device 4 is arranged on the top of the bracket 1, and under the action of gravity, the inner The stored release agent can be discharged via telescopic tubes into the side applicator 2 and the bottom applicator 3 .

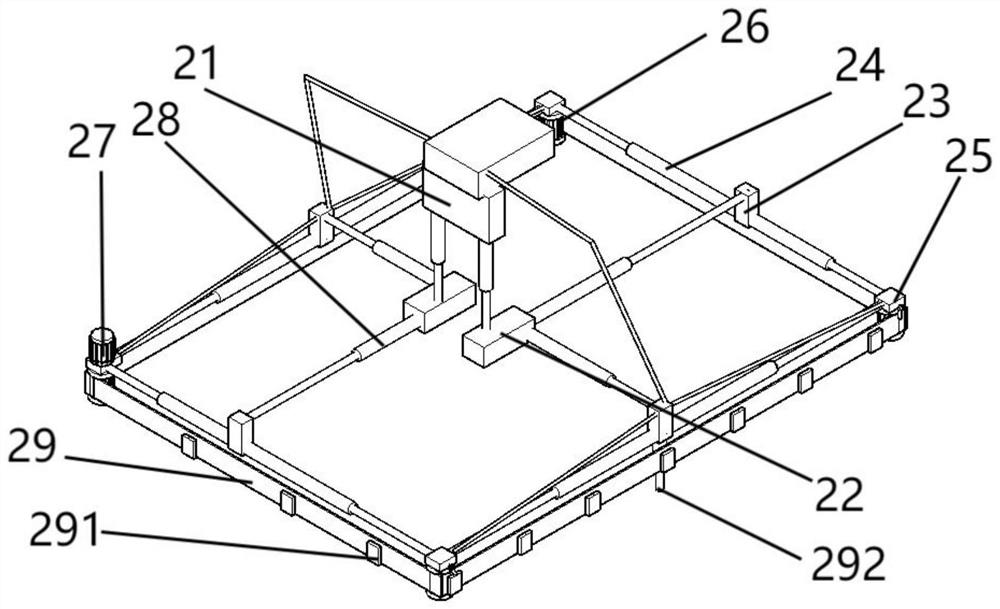

[0033] Such as image 3 As shown, the side smearing device 2 includes a cylinder one 21, a support block one 22, a positioning block 23, a telescopic rod one 24, a liquid storage tank 25, a synchronous p...

Embodiment 2

[0047] Embodiment 2: On the basis of the above embodiments, it also includes a connection block 38 arranged on one of the floor brushes 36. The connection block 38 can drive the floor brush 36 to move to the size of the mold 5 under the drive of the positioning telescopic rod 292. Matching position, the moving process is completed before entering the mold 5.

Embodiment 3

[0048] Embodiment 3: On the basis of the above-mentioned embodiment, the synchronous belt 29 is made of a stretchable material, and the inner side of the synchronous belt 29 is a wavy rack-shaped structure, and its inner side can be close to the synchronous pulley 26 in the specific implementation process And it rotates under the drive of the synchronous pulley 26, and it can also be telescopically transformed under the drive of the synchronous pulley 26 to adapt to the smearing work of different sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com