Pouring operation device for fire-proof glass

A technology for fireproof glass and working device, which is applied in the field of fireproof glass pouring working device, can solve problems such as low production efficiency, and achieve the effects of reducing labor cost, improving utilization rate and optimizing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

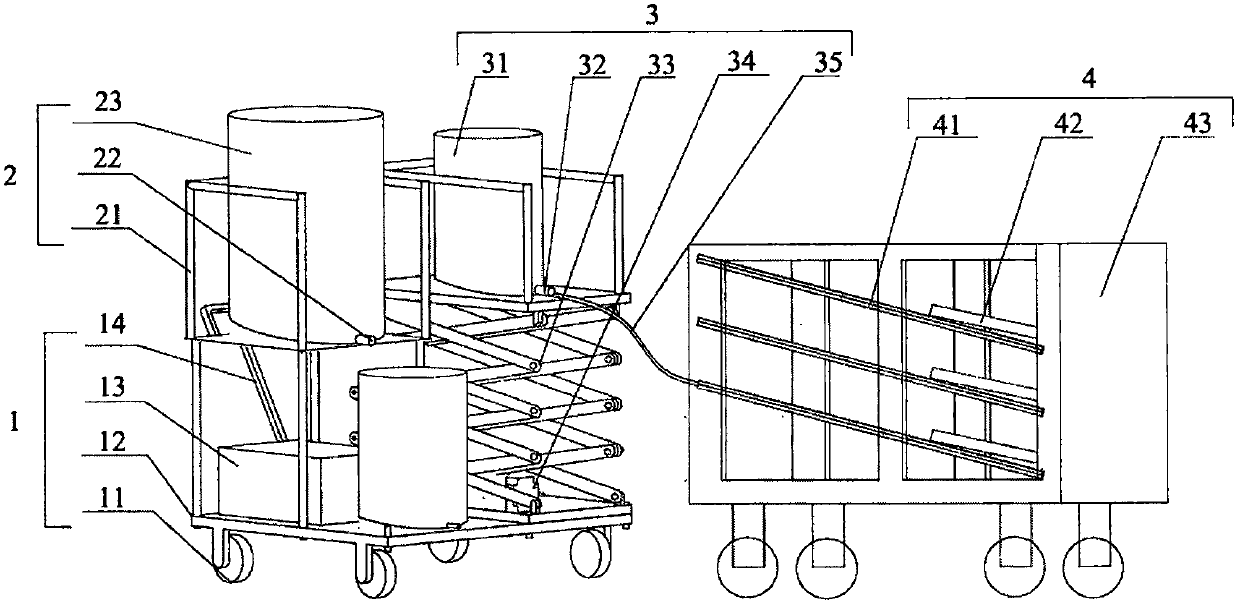

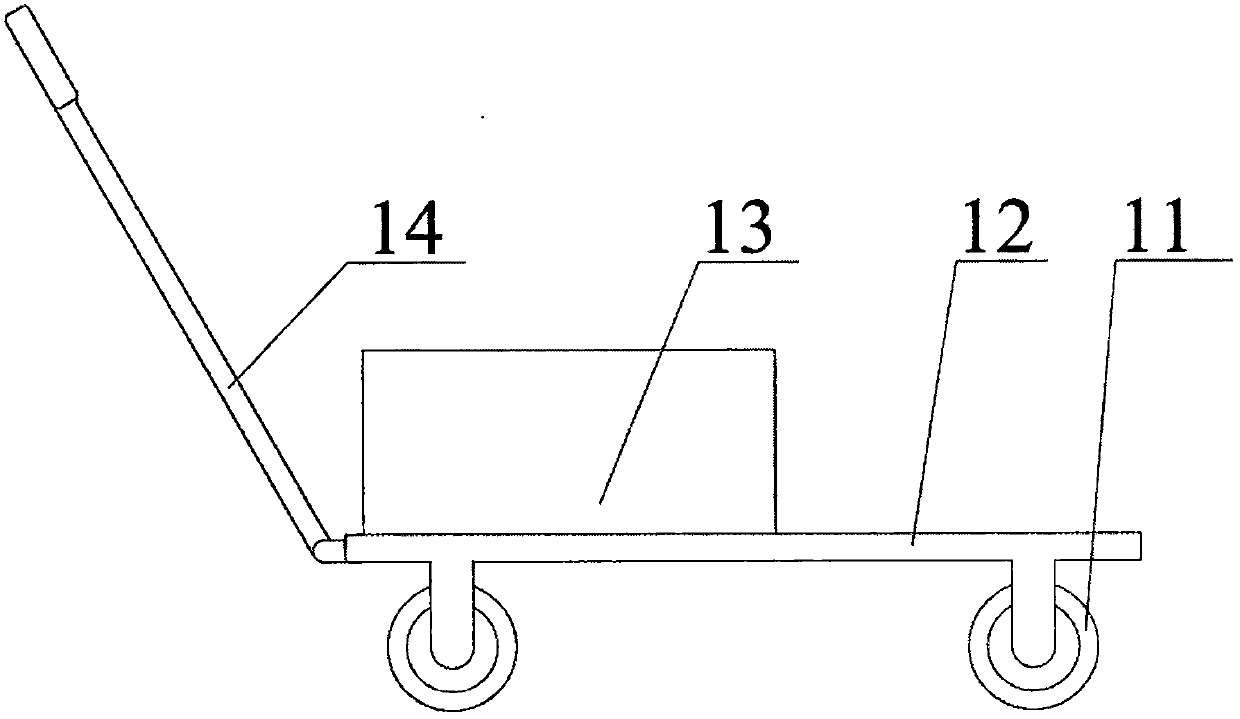

[0034]A fireproof glass pouring operation device, comprising a fireproof liquid pouring device and a glass box storage device (4), the fireproof liquid pouring device including a mobile carrier (1), a fireproof liquid storage and infusion device (2) and a fireproof liquid lifting and pouring device (3), characterized in that: the mobile bearing device (1) includes movable rollers (11), a bottom plate (12), a counterweight (13) and a hand-held support (14), and the fireproof liquid storage infusion device (2) comprising a carrier frame (21), an infusion valve (22) and a fireproof liquid storage tank (23); the fireproof liquid lifting filling device (3) comprises a fireproof liquid filling barrel (31), a filling valve (32), a shear Fork type lifting platform (33), drive motor (34) and perfusion pipe (35); Described glass plate storage device (4) comprises glass box storage frame (41), limit baffle plate (42) and mobile carrier ( 43); the bottom of the carrier frame (21) is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com