Cable-stayed bridge steel box girder closure method and closure system

A technology for a steel box girder and a cable-stayed bridge is applied in the field of a steel box girder closing method and a closing system of a cable-stayed bridge, and can solve the problems such as the jamming of the closing opening, the uneven edges of the steel box girder, and the complicated procedures, and save the counterweight. time, the effect of reducing production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

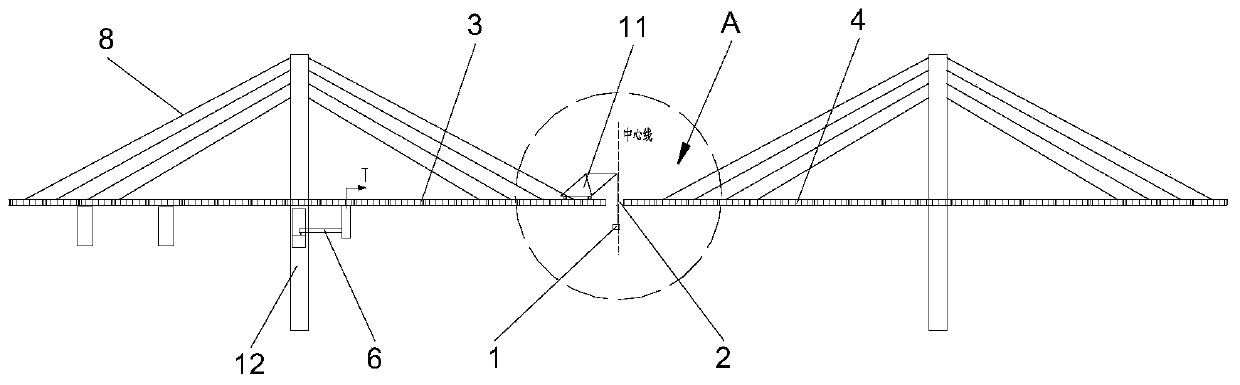

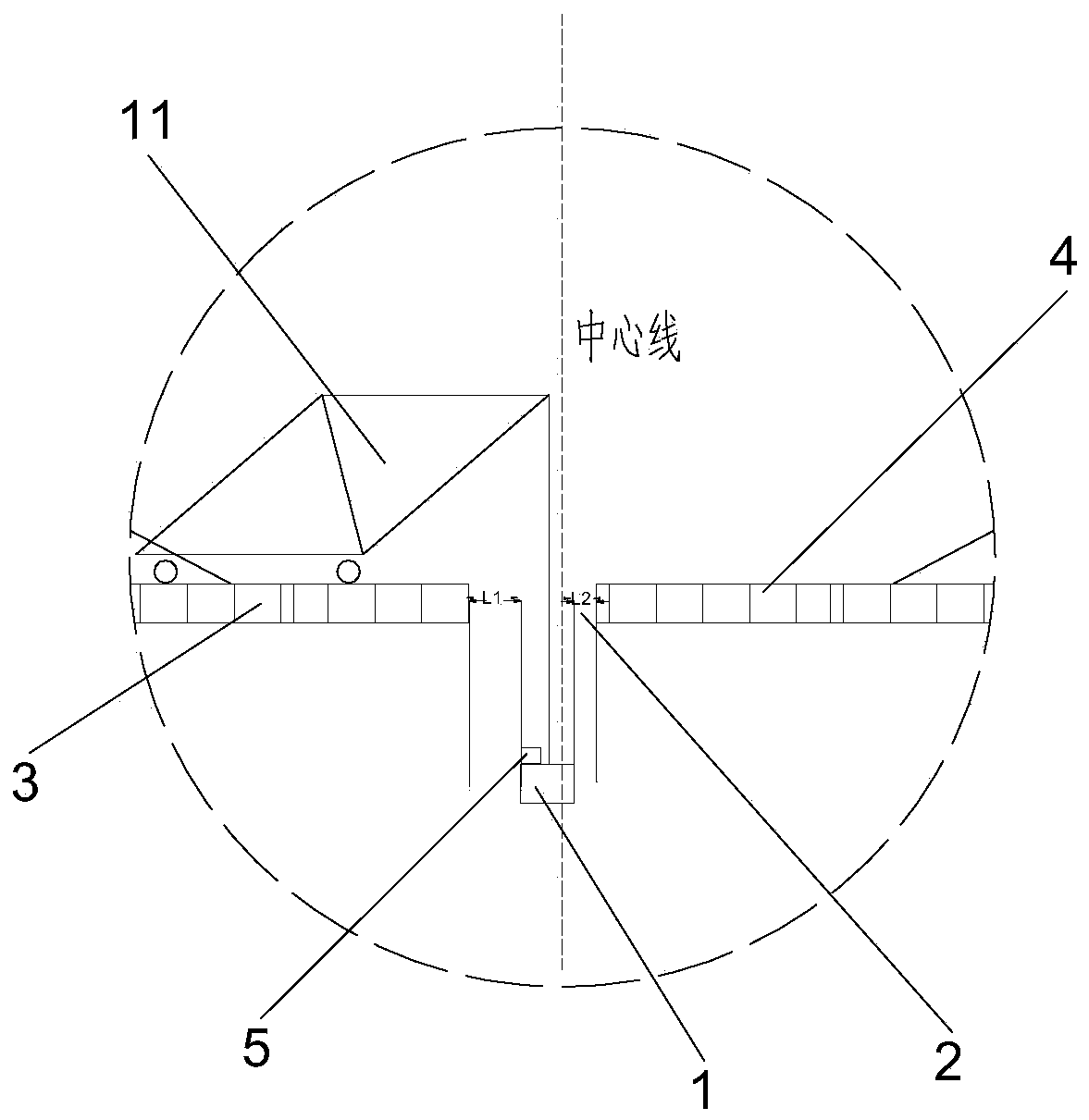

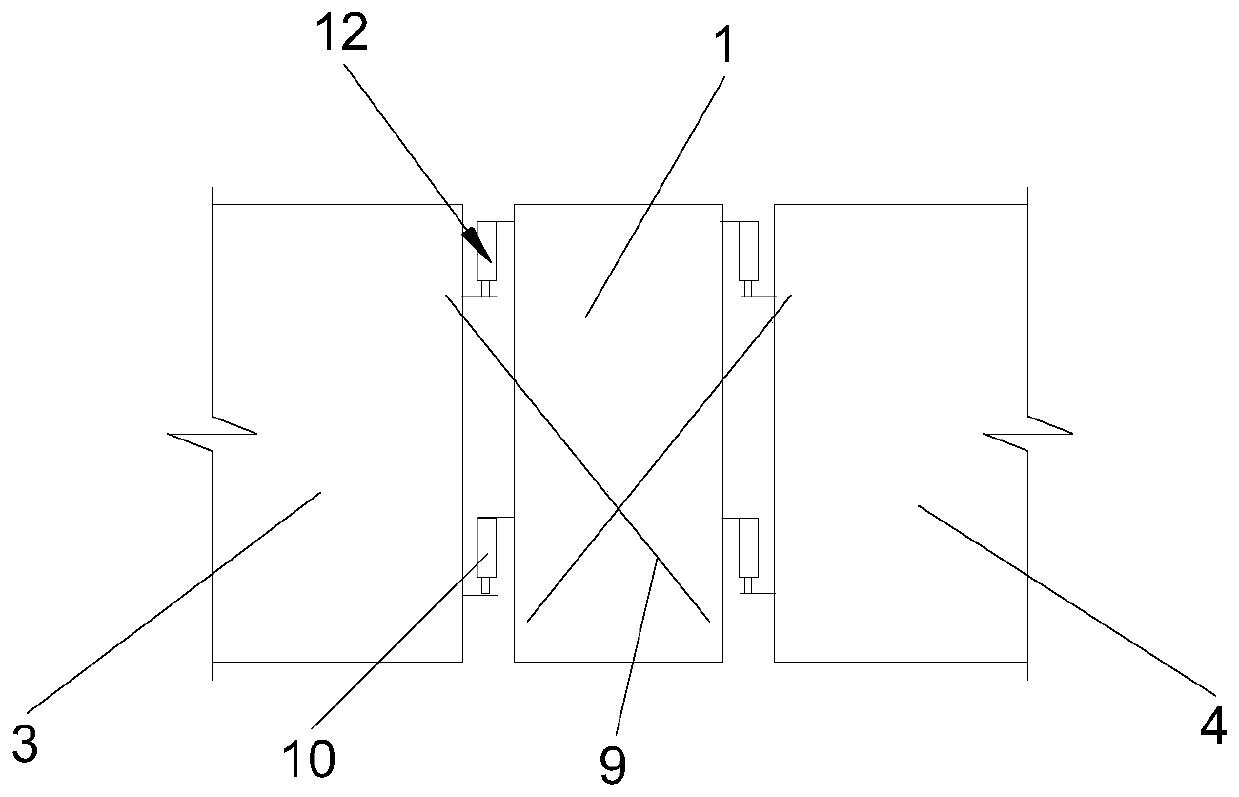

[0053] see figure 1 As shown, the embodiment of the present invention provides a method for closing a steel box girder of a cable-stayed bridge, which includes the following steps:

[0054] Firstly, the steel box girder 1 of the closing section is prefabricated in the factory according to the measured temperature and the spacing of the closing section 2. To make the length of the steel box girder 1 of the closing section, it is only necessary to consider the size of the closing section 2 at a reference temperature of 15 degrees to ensure that the closing section The length of the steel box girder 1 should be made shorter than the length of the closing mouth 2 at the reference temperature, so that the steel box girder 1 of the closing section can be hoisted to the closing mouth 2 smoothly. The embodiment of the present invention does not need to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weld width | aaaaa | aaaaa |

| Weld width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com