Load-bearing concrete perforated brick

A technology of porous bricks and concrete, which is applied to pavements, roads, and building components paved with prefabricated blocks. It can solve problems such as performance that cannot meet the needs of use, and achieve the effects of improving heat insulation, excellent cold protection, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

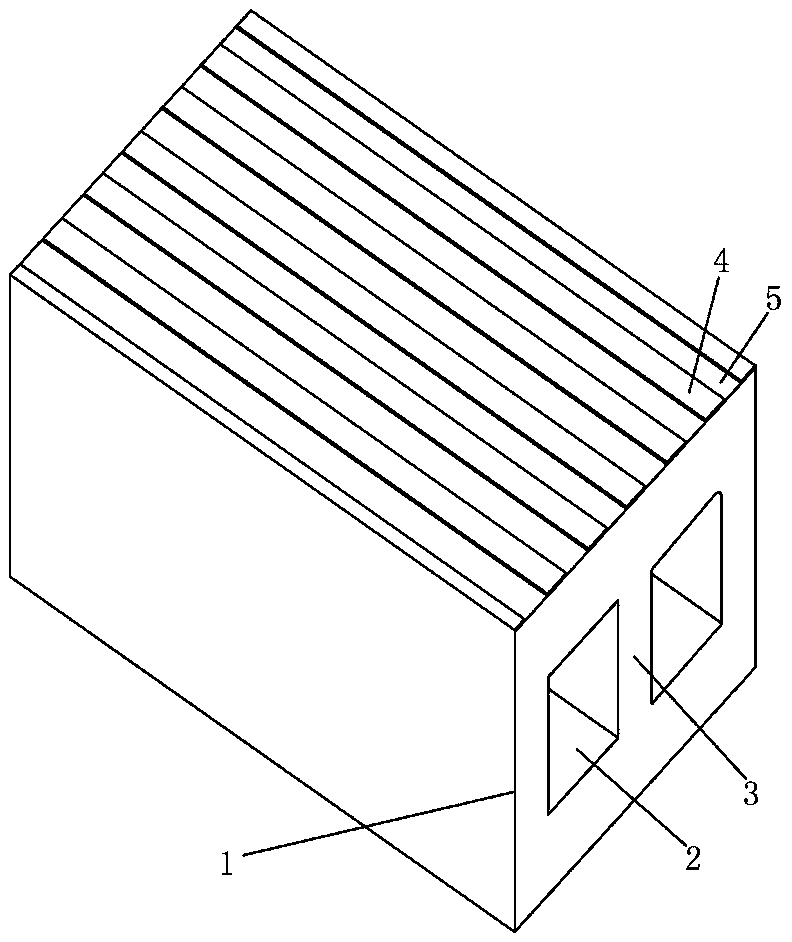

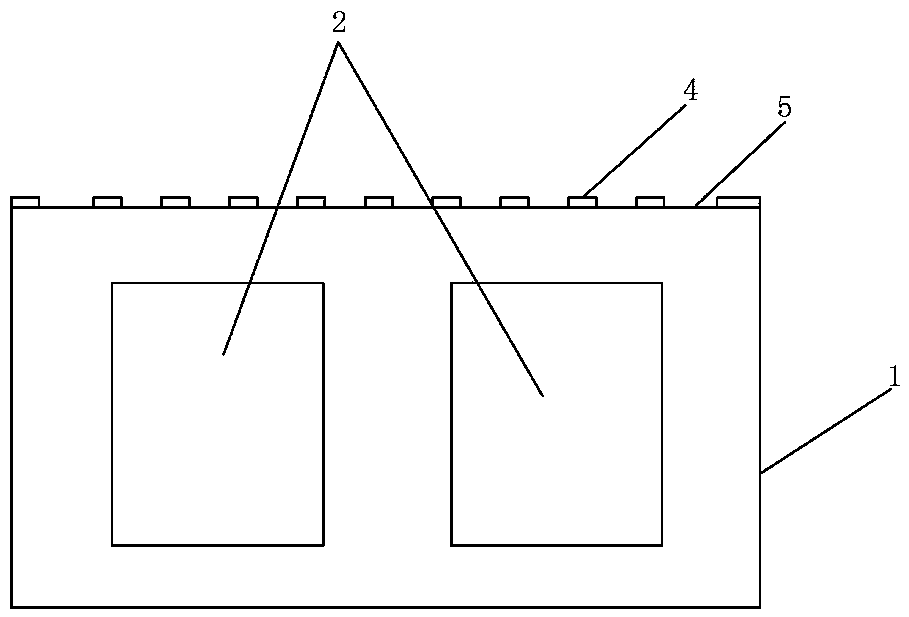

[0018] as attached figure 1 and 2 As shown, the present invention discloses a load-bearing concrete porous brick, which includes a brick body 1, and two through holes 2 are arranged in the brick body 1 along the axial direction, and the two ends of the through holes 2 are respectively located in the brick body On the end faces of both ends in the upper axial direction, two through holes are arranged in parallel, the sum of the cross-sectional areas of the two through holes is greater than half of the end face area in the axial direction of the brick body, and there is a space between the two through holes 2 3. The end surface area of the spacer is smaller than the cross-sectional area of the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com