System and method for variable compression ratio engine

A technology of compression ratio and engine, applied in engine control, machine/engine, gear transmission mechanism, etc., can solve problems such as transient acceleration and slow acceleration affecting the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

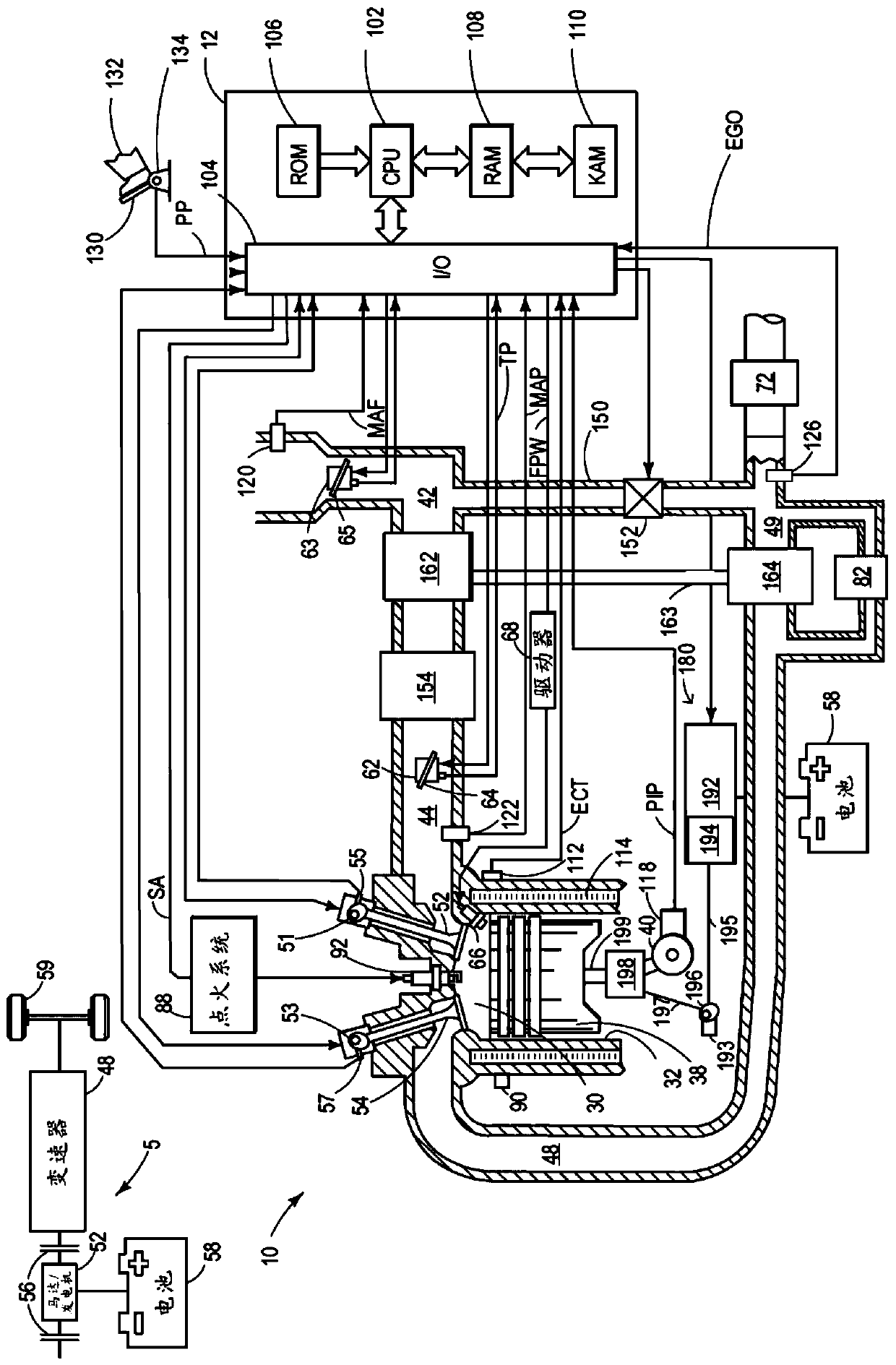

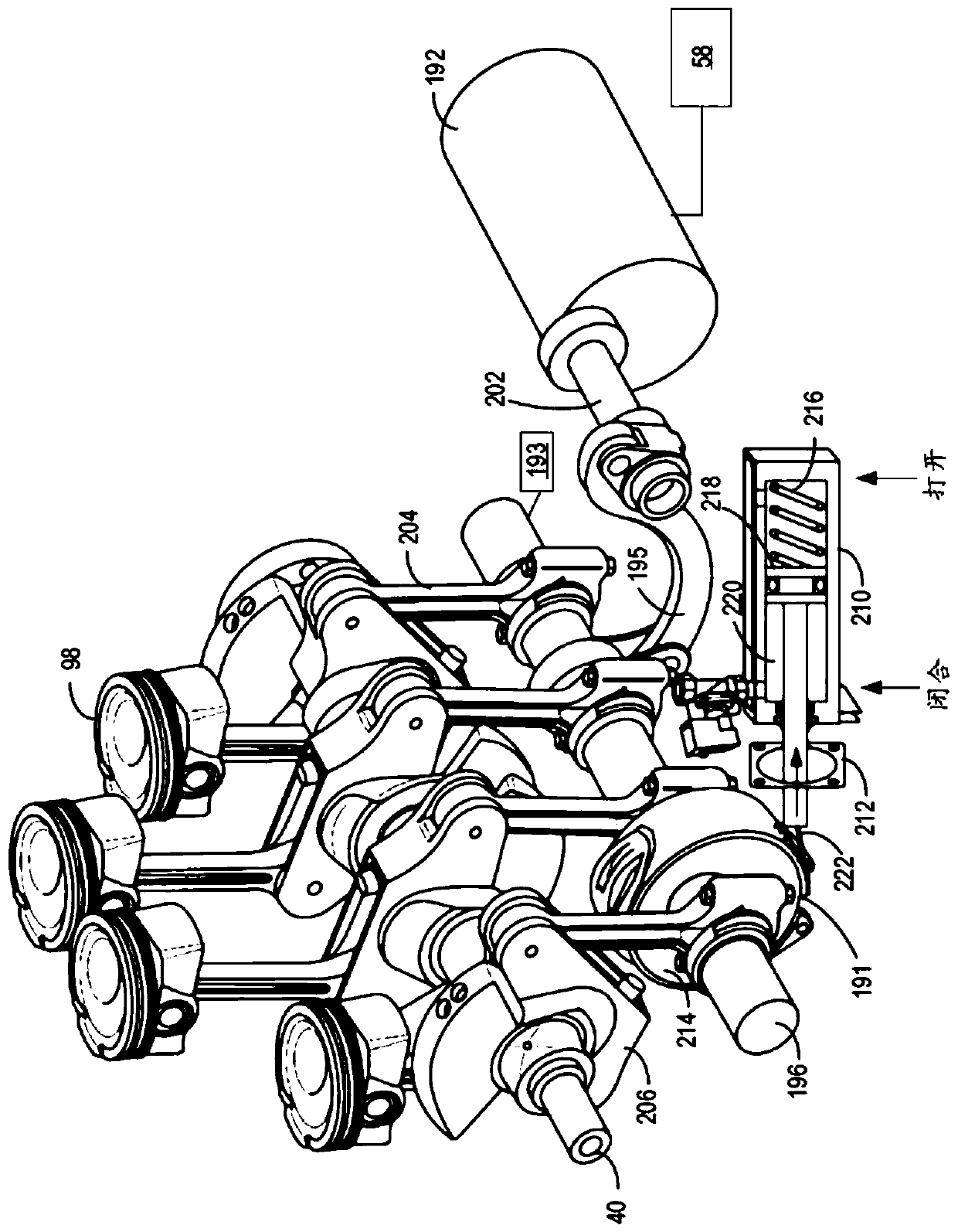

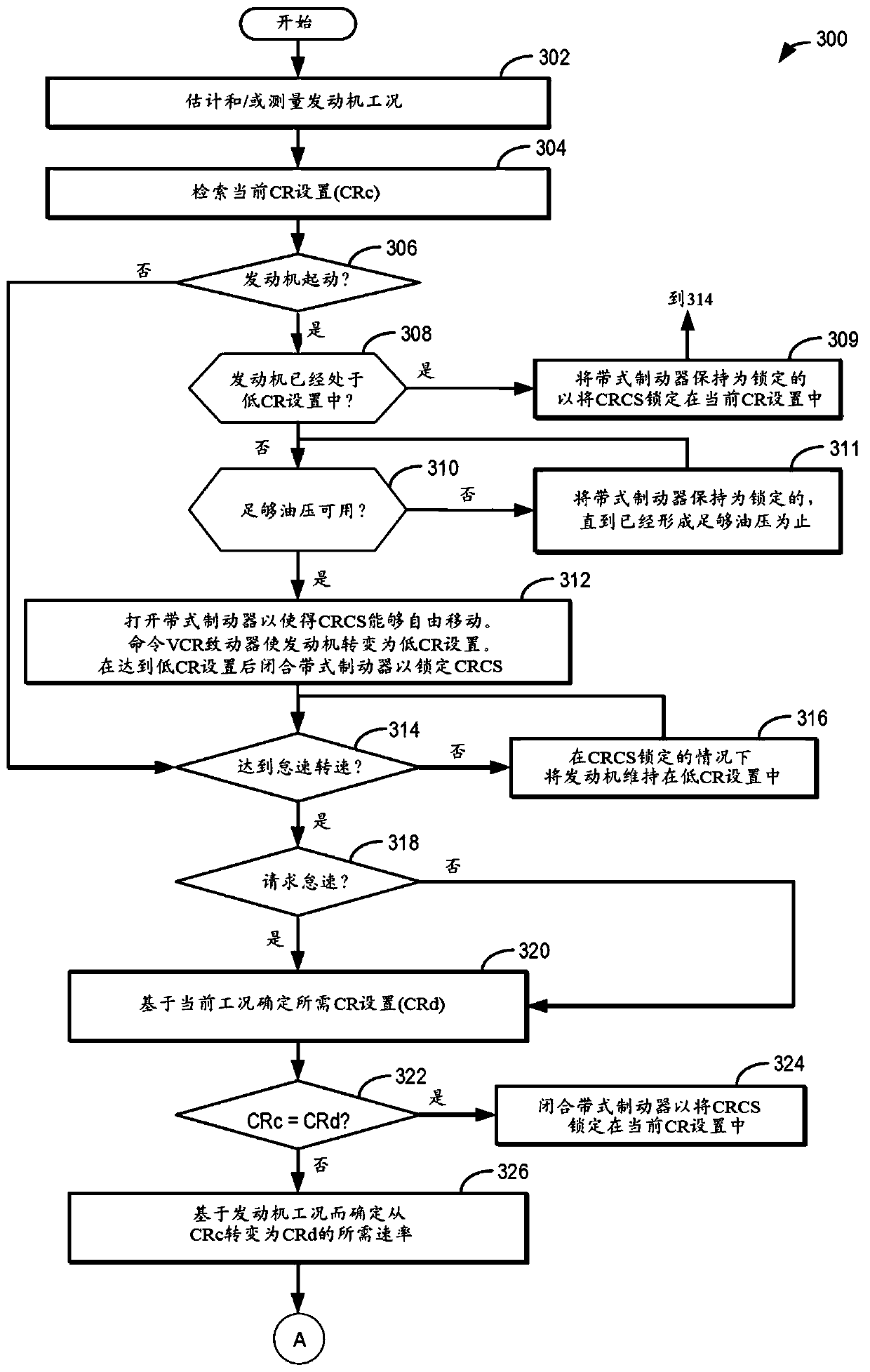

[0020] The following description relates to systems and methods for an engine system configured with a variable compression ratio (VCR) mechanism, as referenced Figure 1-2 The engine system is described. The controller can be configured to execute control programs such as Figure 3-4 An example procedure to lock the band brakes coupled to the VCR control shaft to maintain a fixed CR setting, and to vary the brake pressure applied by the band brakes to improve CR transitions. Such as Figure 5 Elaborating, the brake pressure can be adjusted during CR transitions based on the engine torque applied to the control shaft, which is known from engine speed-load ( Figure 8 ). Brake pressure applied via band brakes can be adjusted via hydraulic or electric actuators, such as Figures 6A-6B Elaborate. The controller may lock the band brakes when the engine's CR setting is in the high or low zone, and unlock the band brakes and adjust brake pressure when the CR setting is in the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com