Quasi-zero stiffness vibration isolator with low frequency broadband characteristics

A quasi-zero stiffness, vibration isolator technology, applied in springs/shock absorbers, vibration suppression adjustment, non-rotational vibration suppression, etc. Long service life, easy control, obvious effect of innovation advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

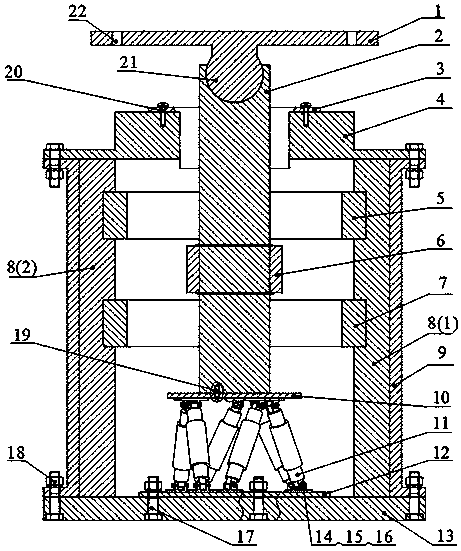

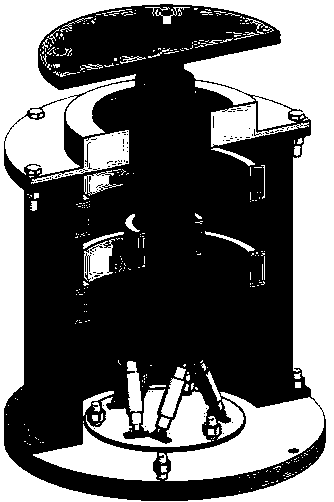

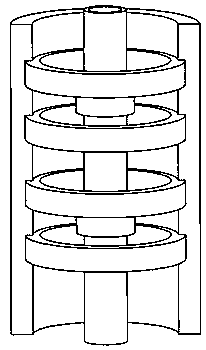

[0025] As shown in the figure, the present invention is a quasi-zero-stiffness vibration isolator with a PAM (pneumatic artificial muscle), a new quasi-zero-stiffness vibration isolator with three magnetic rings. On the whole, it is composed of a spherical hinge bearing platform 1, an upper end cover, a shell, a three-ring negative stiffness mechanism, a PAM positive stiffness mechanism and a base. It specifically includes a ball joint bearing platform 1, a central shaft 2, a linear bearing 3, an upper end cover 4, an upper magnetic ring 5, an inner magnetic ring 6, a lower magnetic ring 7, an inner shell 8, an outer shell 9, and the upper cover of the pneumatic artificial muscle 10. Pneumatic artificial muscle 11, mounting seat 12 and base 13 of pneumatic artificial muscle. The ball joint bearing platform 1 is at the top, and has four through holes 22 , through which the vibration-isolated object is directly connected with the ball joint bearing platform 1 by bolts through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com