Device and method for measuring temperature rise efficiency of low-state compression component

A technology of state compression and efficiency measurement, which is applied in the direction of measurement devices, machine/structural component testing, heat measurement, etc. It can solve the problems of large error in temperature measurement results, affecting the accuracy of temperature rise efficiency, lack of accurate and effective measurement methods, etc. , to achieve the effect of reducing heat conduction error, improving accuracy and reducing measurement uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

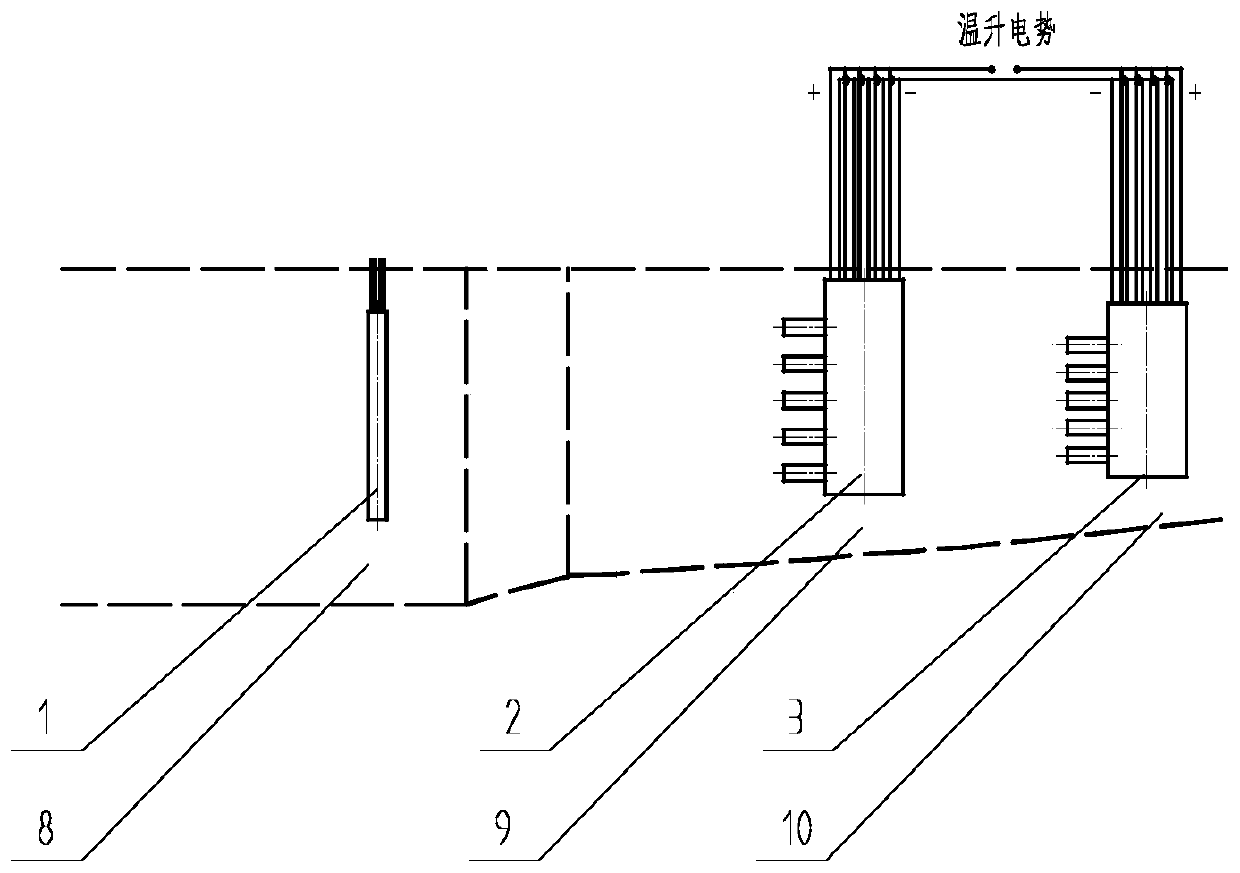

[0042] Such as figure 1 As shown, a low-state compression part temperature rise efficiency measurement device disclosed in this embodiment, a voltage regulator box 8 platinum resistance temperature sensor 1, a compression part inlet temperature sensor 2, a compression part outlet temperature sensor 3, a thick wire 4, a thin wire 5. The shielding cover 6 and the sensor housing 7 . For the convenience of description, the compression part inlet temperature sensor 2 and the compression part outlet temperature sensor 3 are collectively referred to as temperature sensors, that is, the temperature sensor is the compression part inlet temperature sensor 2 or the compression part outlet temperature sensor 3, and the names are determined according to the layout of the inlet or outlet measurement section.

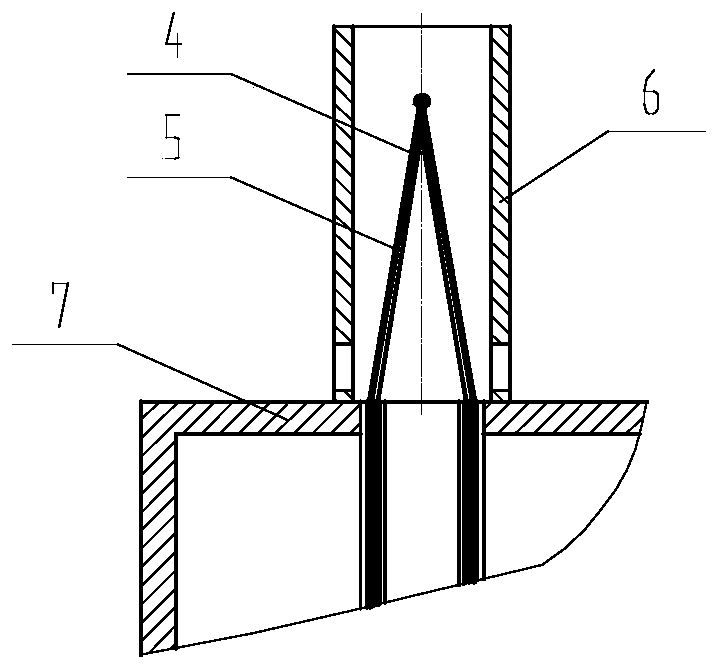

[0043] Such as figure 2 As shown, both the inlet temperature sensor 2 and the outlet temperature sensor 3 of the compression part adopt a double-wire multi-point single-shielding st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com