Liquid rocket engine short type thermocouple steady state calibration device

A technology of liquid rockets and calibration devices, which is applied to measuring devices, thermometer testing/calibration, and heat measurement, etc. It can solve the problems of heat conduction error affecting the measurement accuracy of temperature parameters, the steady-state characteristics of temperature sensors vary greatly, and the selection of temperature sensors. , to avoid excessive differences, improve measurement accuracy, and reduce radiation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

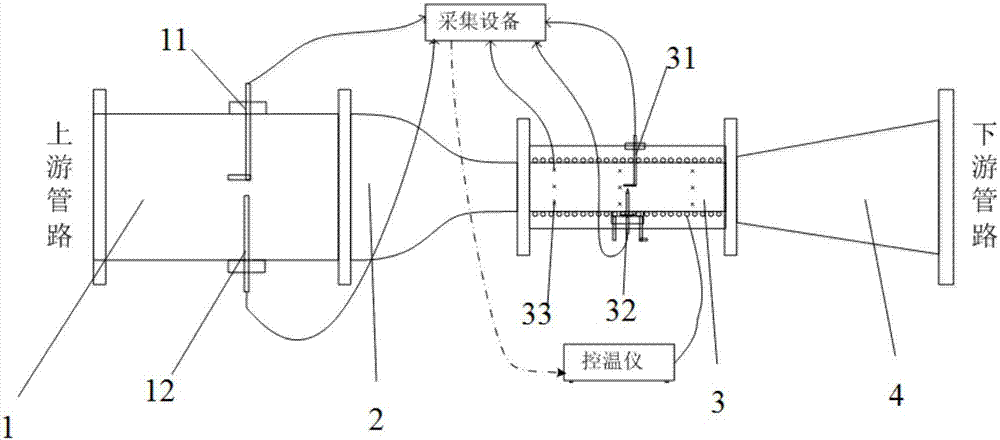

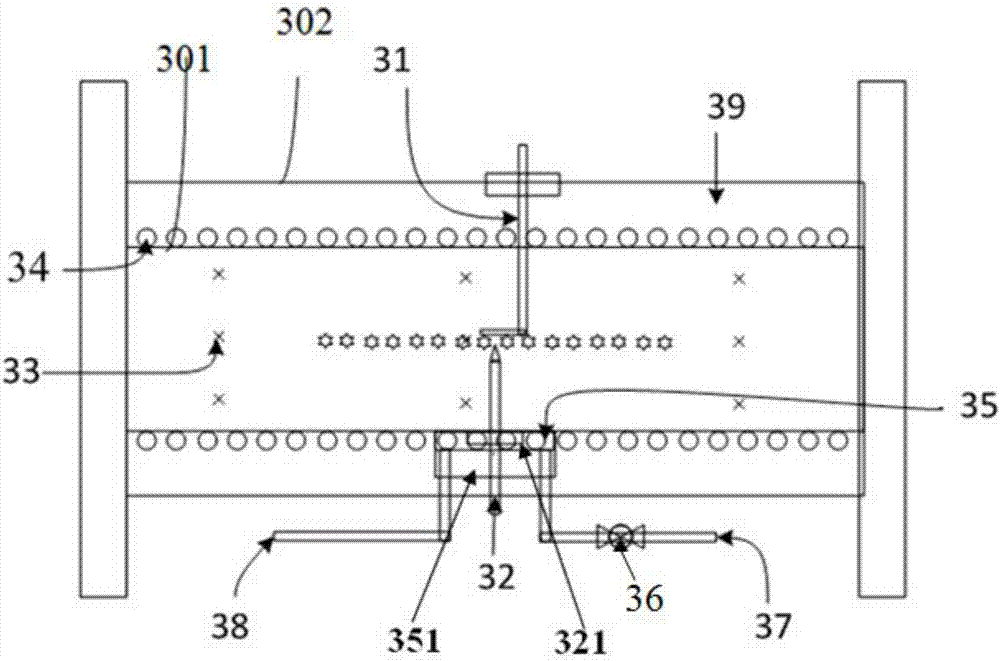

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

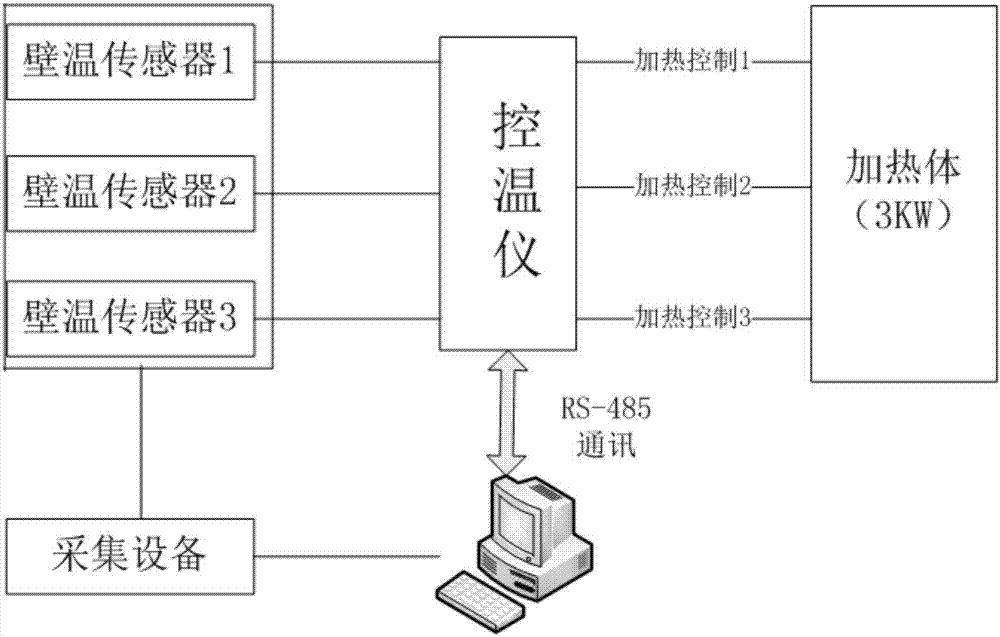

[0043]The present invention takes the oxygen-enriched high-temperature temperature sensor of a new generation of large-carrying engines as the research object. Research on heat conduction correction calibration technology of type thermocouple temperature sensor, and establish a set of steady-state calibration device. In this device, the temperature measurement result of the reference temperature sensor is considered to be the temperature standard value. Under certain working conditions, the short thermocouple temperature sensor is calibrated by comparing the temperature measurement results of the short thermocouple and the reference temperature sensor. .

[0044] Study the influence of the length-to-diameter ratio of the short thermocouple temperature sensor (thermocouple temperature measurement part) and the mounting support on the heat conduction error under the act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com