A non-destructive testing method for the cutting edge of tunnel boring machine hob

A technology for tunnel boring machines and non-destructive testing, which is applied to instruments, uses sonic/ultrasonic/infrasonic waves to analyze solids, analyze materials, etc. It can solve the problem of difficulty in ensuring the progress of construction, high cost, and non-destructive testing of hob cutter rings to obtain internal defect information. The problem of unstable driving process of roadheader, etc., achieves the effect of reliable quality, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

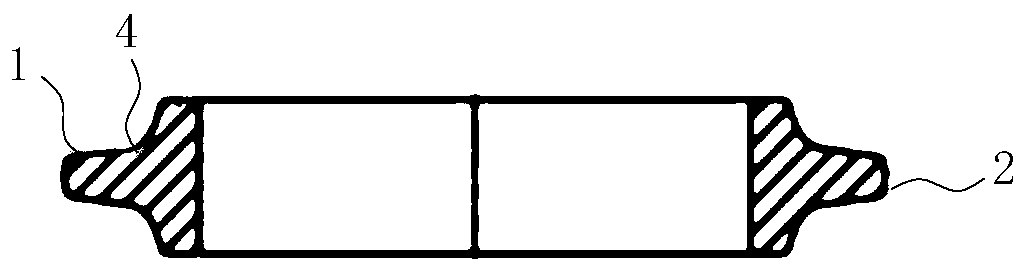

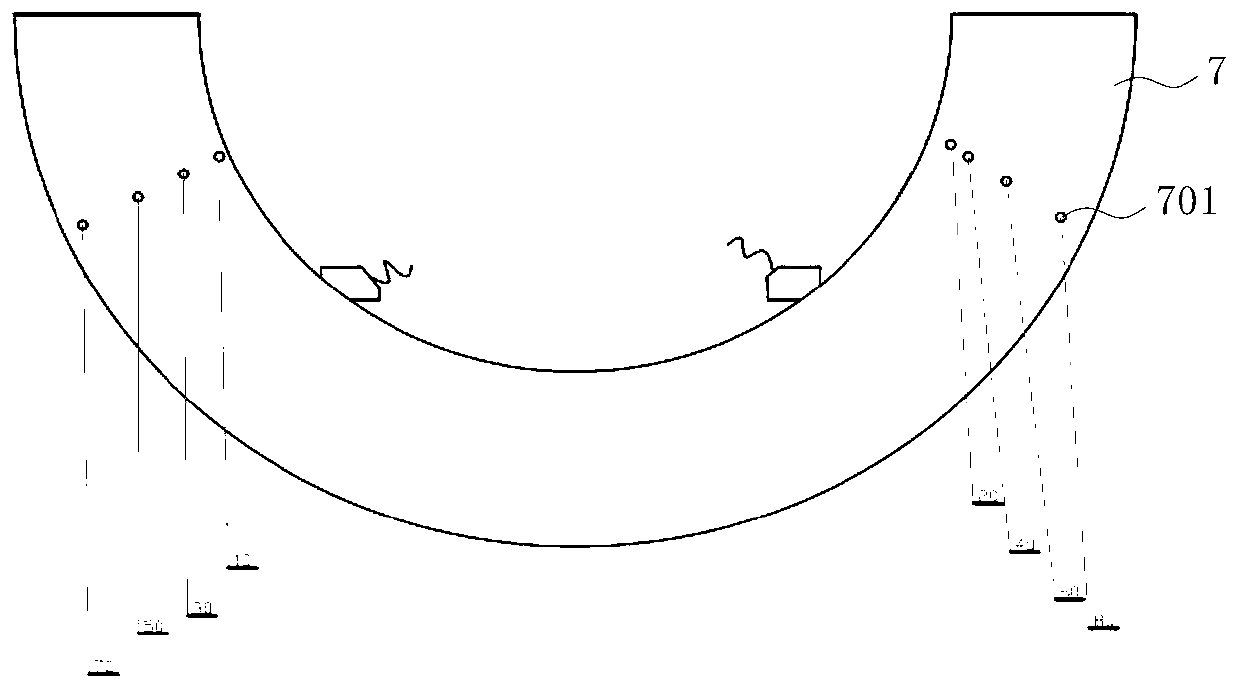

[0034] Due to its special structure and shape, the hob cutter ring has no testing procedures for this kind of test piece in China, and the technical difficulty is relatively high. According to the analysis and research of domestic peers, ultrasonic flaw detection alone is not enough to solve this technical problem, and ultrasonic and The two technologies of magnetic particle flaw detection are used together. The present invention adopts ultrasonic flaw detection technology in the flaw detection of the blade portion. Because the transition arc part is not the main working surface, the magnetic particle flaw detection technology can solve this technical problem.

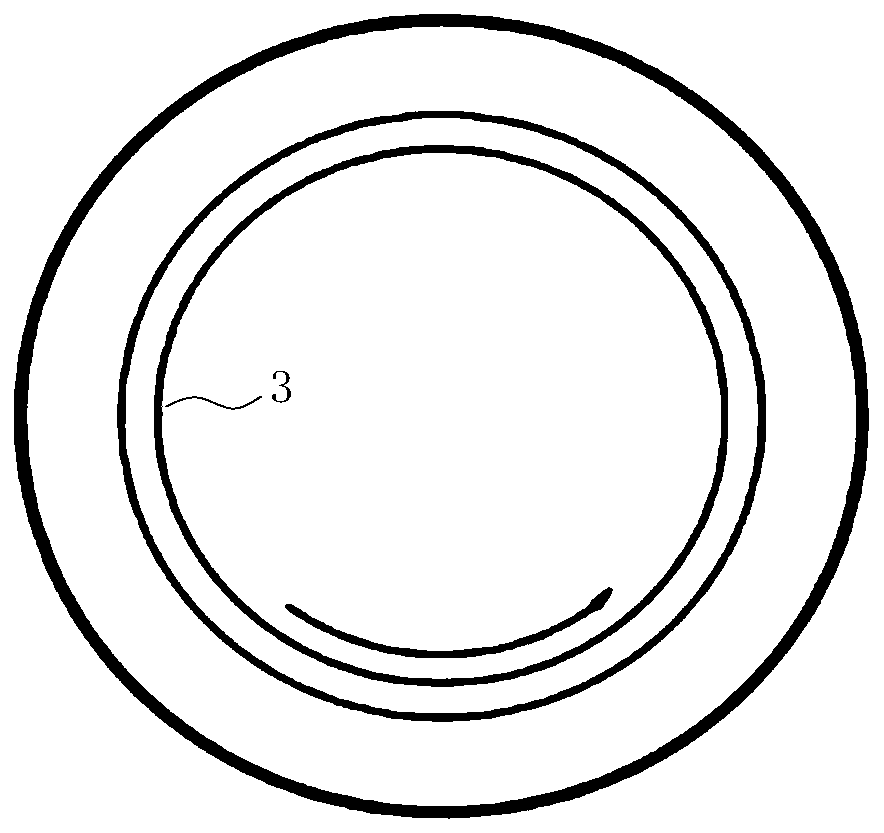

[0035] See attached figure 1 And attached figure 2 , a kind of non-destructive testing method of the hob cutter ring edge 1 of the present invention is: respectively check the radial direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com