Gas-insulated metal-enclosed power transmission line and axial expansion joint thereof

A gas-insulated metal, axial expansion and contraction technology, applied in the direction of adjusting/maintaining mechanical tension, relieving mechanical tension devices, etc., can solve the problems of limited compensation and limited expansion and contraction of expansion joints, and achieve increased stability and reduced structure. Size, the effect of reducing the value of the passing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

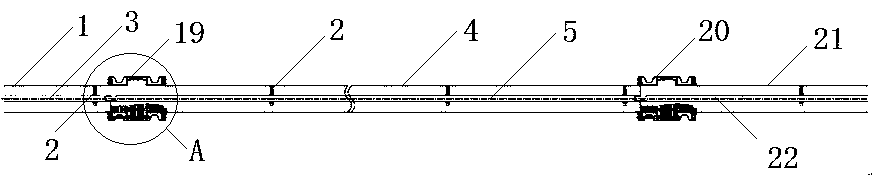

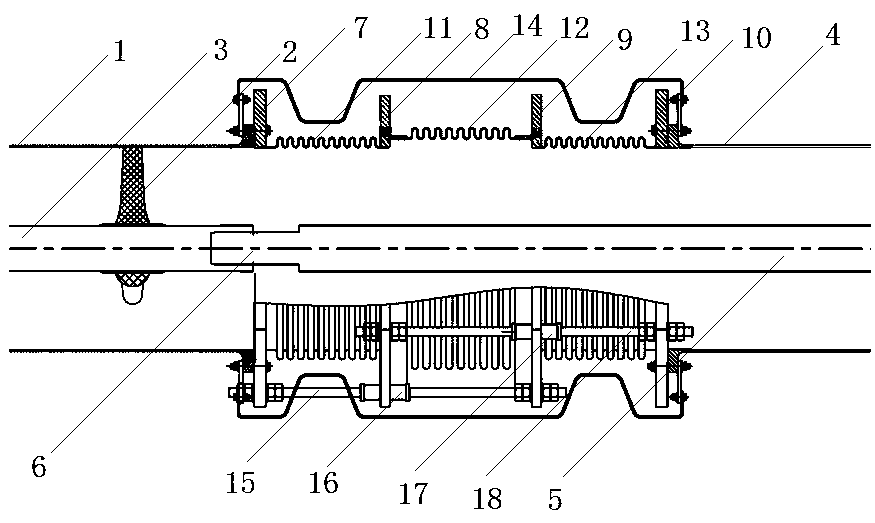

[0055] Embodiments of the gas-insulated metal-enclosed transmission line of the present invention will be further described below in conjunction with the accompanying drawings.

[0056] The gas-insulated metal-enclosed power transmission line in the present invention includes a large number of pipe sections, each pipe section includes an outer cylinder and a busbar coaxially installed in the outer cylinder, a large number of pipe sections are connected in series coaxially, and some adjacent pipe sections are connected in series with axial expansion The two ends of the axial expansion joint are sealed and connected with the outer cylinders of the two adjacent pipe sections, and the busbars of the two adjacent pipe sections are connected by plugging.

[0057] For ease of description, the axial expansion joint and the pipe section sealingly connected with the axial expansion joint form a connection unit, the connection unit includes a housing and a busbar coaxially installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com