In-situ high-pressure rotary jet grouting injection repairing device for organic contaminated sites

A high-pressure rotary spray, organic pollution technology, applied in the restoration of polluted soil, measuring devices, instruments, etc., can solve the problem of lack of ideal real-time detection methods, and achieve the effect of improving the efficiency of in-situ remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The repair steps are as follows:

[0029] (1) Transport the device components to the organic polluted site, level the organic polluted site, and construct the water-stop curtain;

[0030] (2) Arrange the drilling points by measuring;

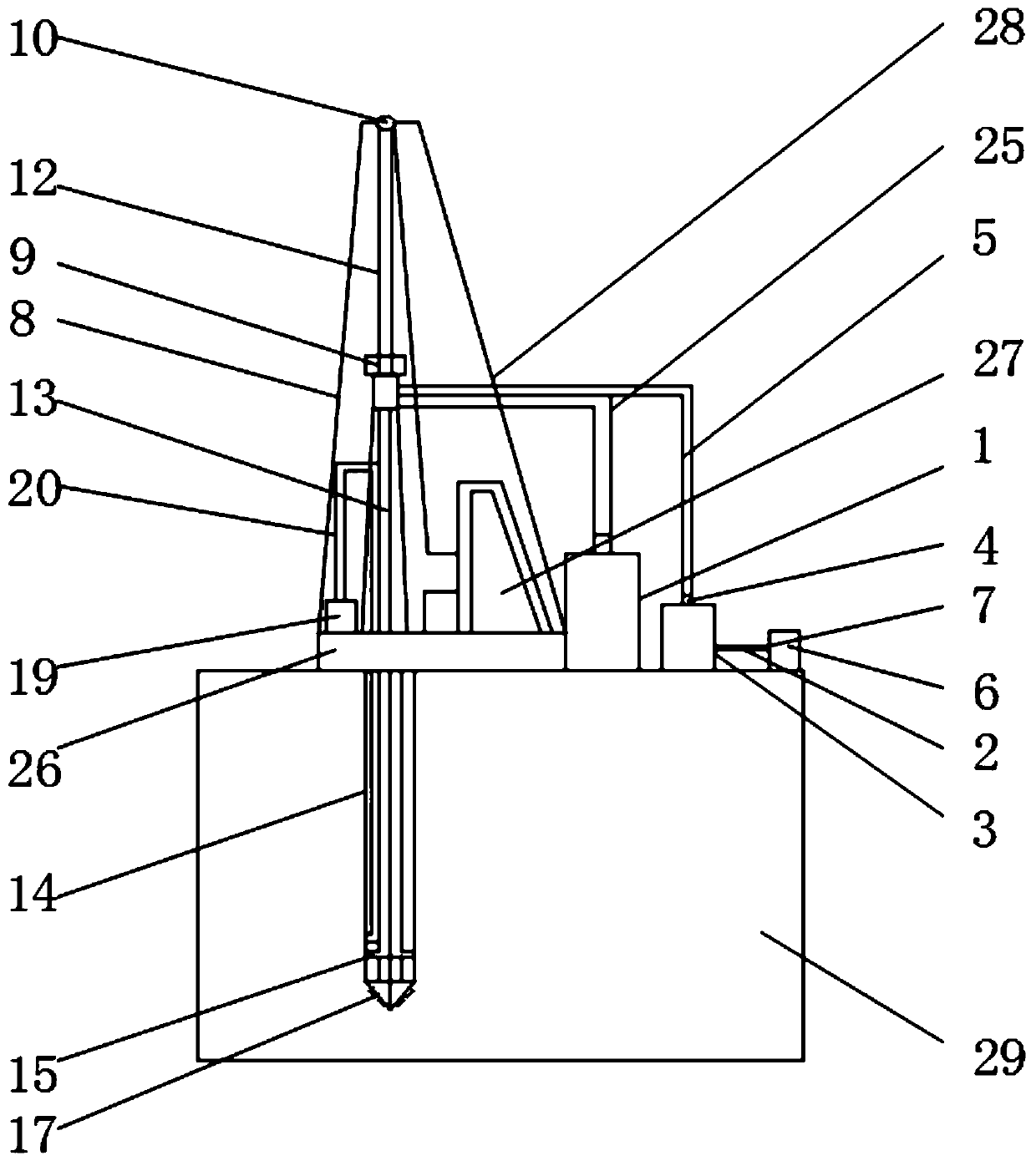

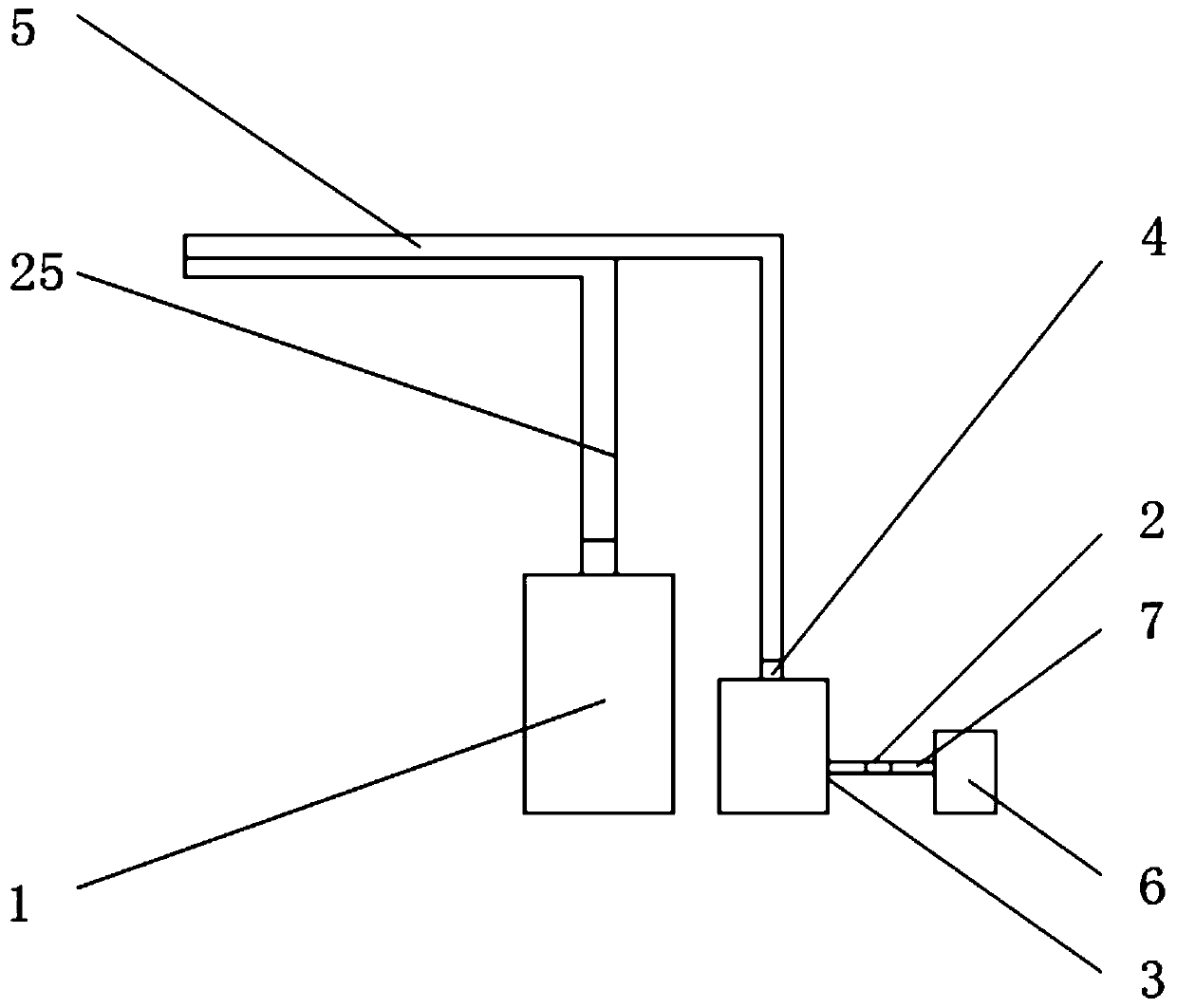

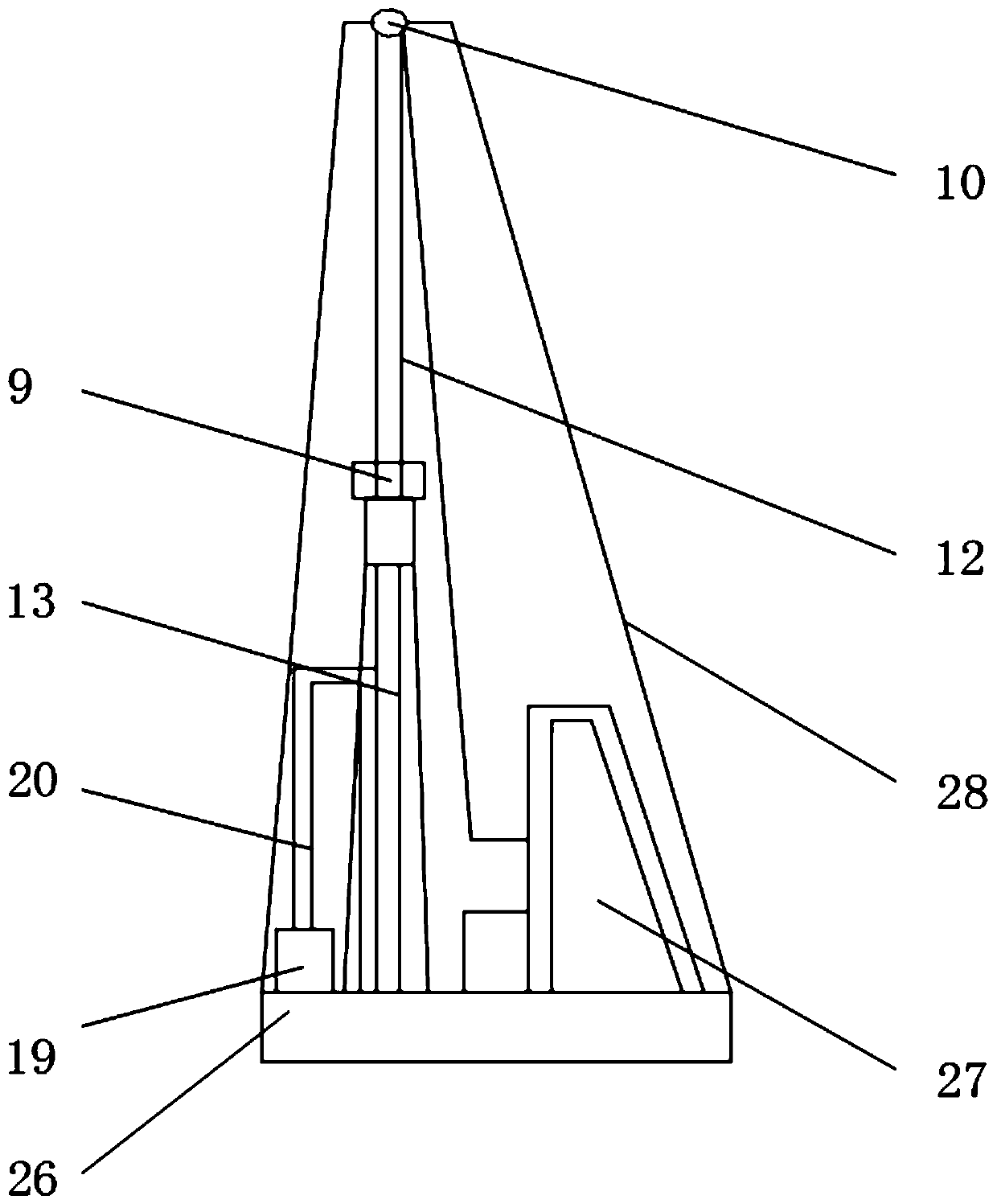

[0031] (3) Transport the in-situ high-pressure rotary jet injection repair device to the point for installation, and its components include dispensing station 1, inlet valve port 2, high-pressure grouting pump 3, outlet valve 4, high-pressure grouting pipe 5, air compressor Machine 6, compressed air pipeline 7, rotary jet drilling rig 8, power head 9, automatic lifting mechanism 10, high-pressure jet inner pipe 11, drill pipe 12, high-pressure jet triple drill pipe inner pipe 13, high-pressure jet triple drill pipe outer pipe 14 , medicament injection nozzle 15, air injection nozzle 16, drill bit 17, hard alloy block 18, volatile organic gas rapid detector 19, medicament injection pipeline 25, device fixed bottom plate 26, control box 27...

Embodiment 2

[0036] The repair steps are as follows:

[0037] (1) Transport the device components to the organic polluted site, level the organic polluted site, and construct the water-stop curtain;

[0038] (2) Arrange the drilling points by measuring;

[0039] (3) Transport the in-situ high-pressure rotary jet injection repair device to the point for installation, and its components include dispensing station 1, inlet valve port 2, high-pressure grouting pump 3, outlet valve 4, high-pressure grouting pipe 5, air compressor Machine 6, compressed air pipeline 7, rotary jet drilling rig 8, power head 9, automatic lifting mechanism 10, high-pressure jet inner pipe 11, drill pipe 12, high-pressure jet triple drill pipe inner pipe 13, high-pressure jet triple drill pipe outer pipe 14 , medicament injection nozzle 15, air injection nozzle 16, drill bit 17, hard alloy block 18, volatile organic gas rapid detector 19, organic hose 20, medicament injection pipeline 25, device fixed bottom plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com