Electric power construction tool

A technology for electric power construction and tools, applied in the field of electric power construction tools, can solve problems such as inspection leaks, loose screws, life safety threats, etc., and achieve the effect of reducing strong vibration force and reducing the frequency of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

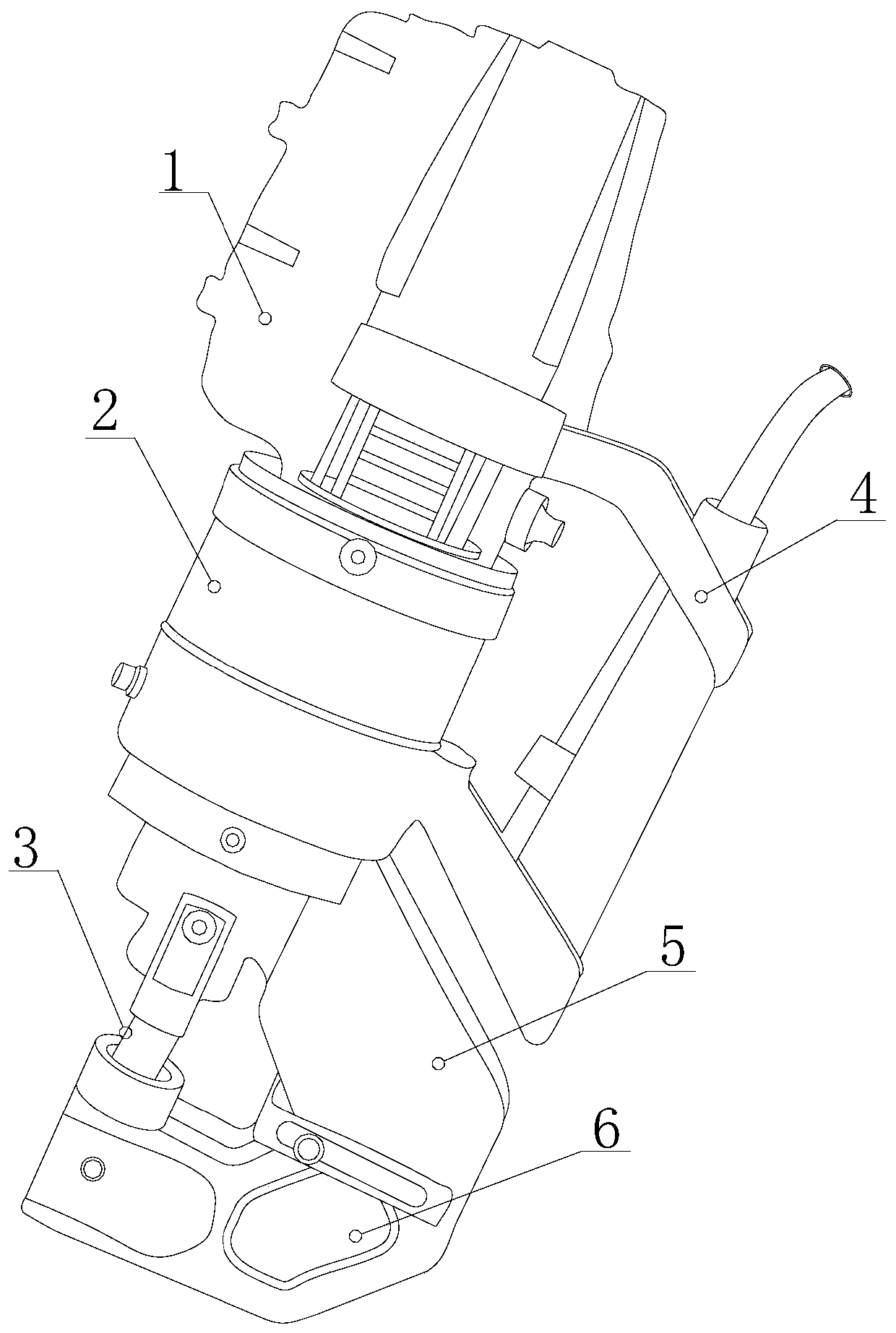

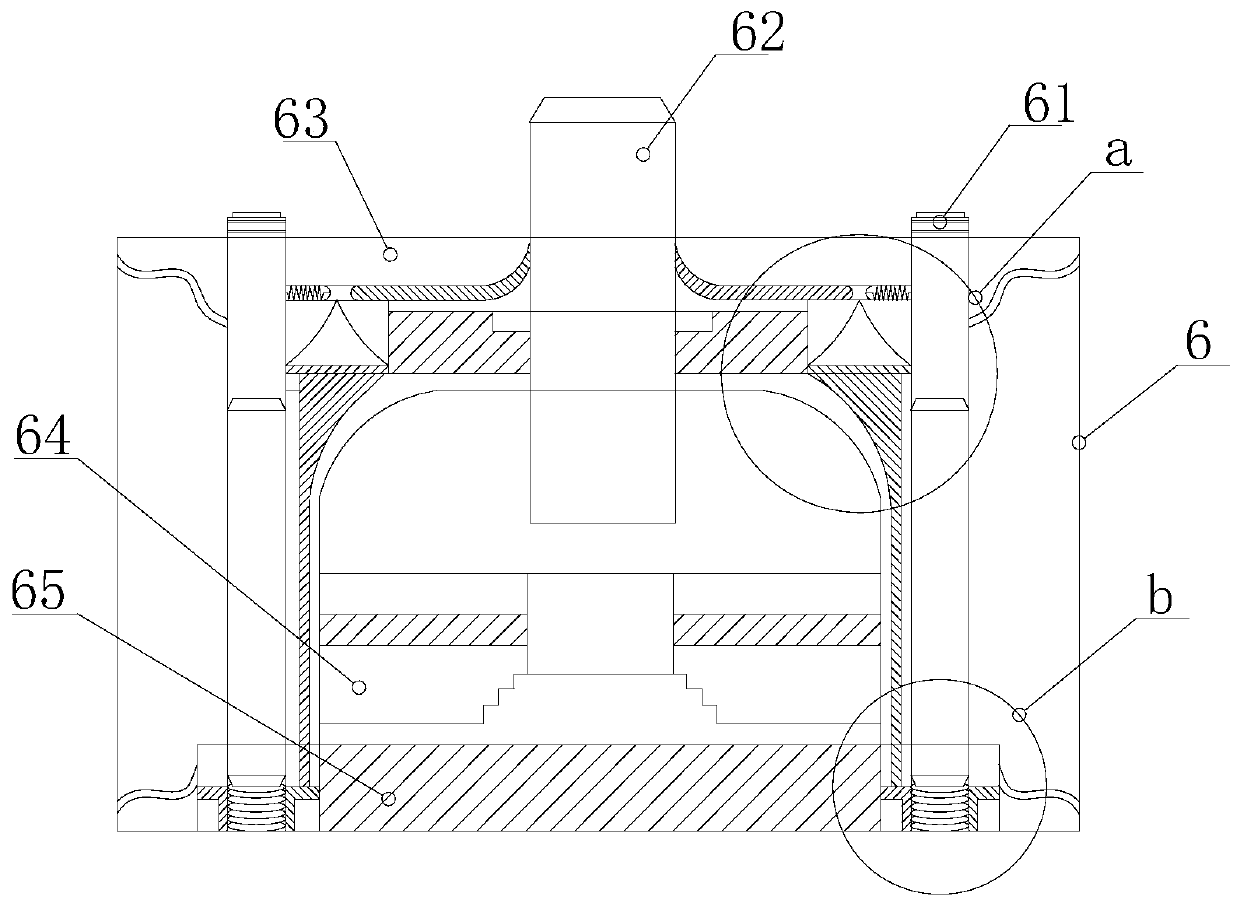

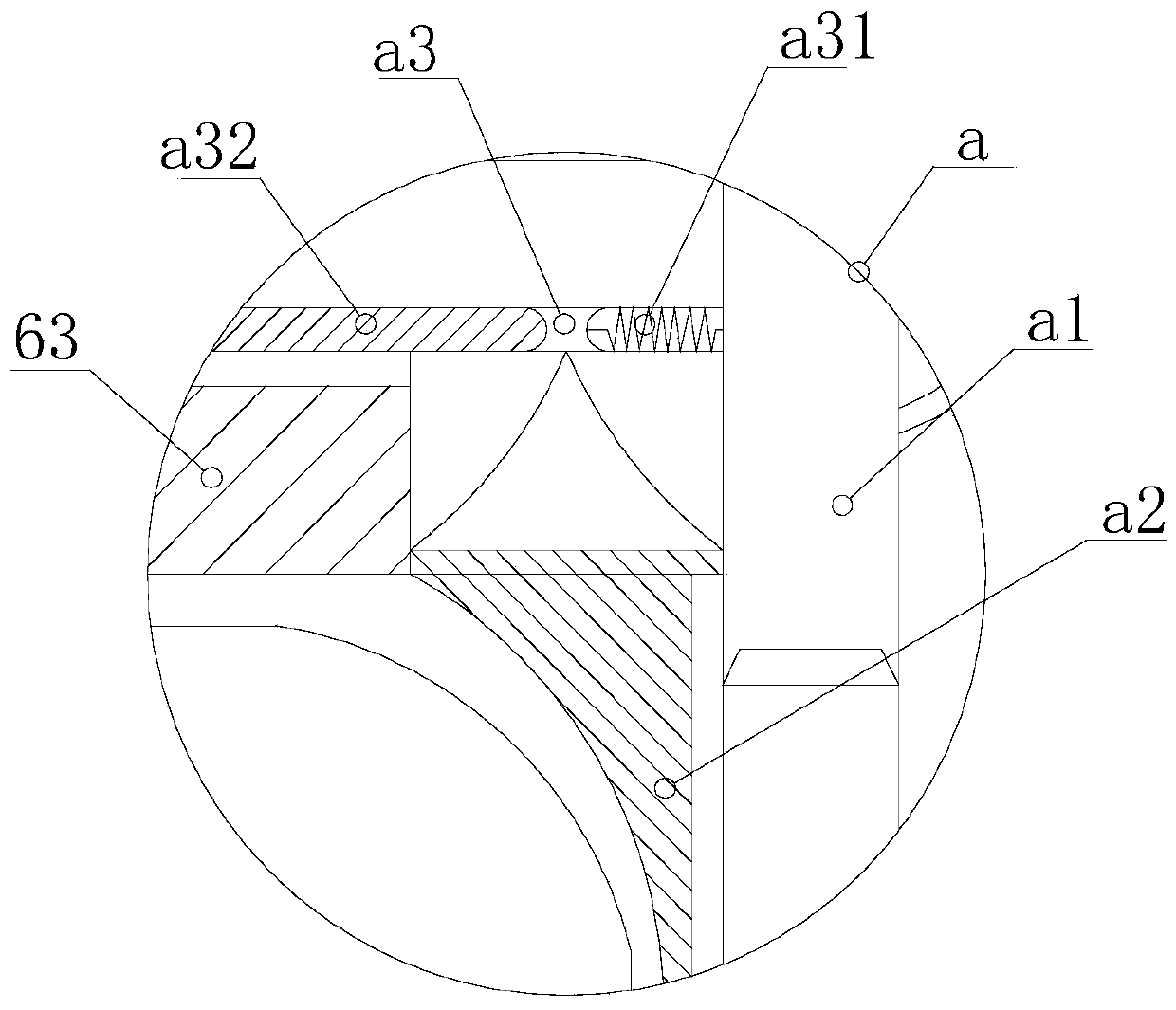

[0027] Such as Figure 1-Figure 6 As shown, the present invention provides a kind of electric construction tool, and its structure comprises machine head 1, fuselage 2, working head 3, handle 4, brace plate 5, die structure 6, and the interior of described machine head 1 is equipped with electric pump , the electric pump is connected with the oil delivery hose located inside the fuselage 2, the fuselage 2 is equipped with a working head 3 through a mechanical connection, the die structure 6 is fixed by a brace plate 5, and is opposite to the working head 3, Described die structure 6 comprises bolt hole 61, die opening 62, upper die 63, lower die 64, mold base 65, hole probe a, support flat seat b, and described upper die 63 and lower die 64 adopt bolt connection, so The die opening 62 is vertically opposite to the working head 3, the die opening 62 is arranged on the upper die 63, the lower die 64 is integrated with the mold base 65, and one end of the hole detection part a is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com