Material pouring device for building construction

A technology of building construction and dumping device, which is applied in the direction of transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of no pressure-reducing and shock-absorbing functions, trolleys are inconvenient to dump, and low safety, so as to save time Labor-saving work efficiency, high safety, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

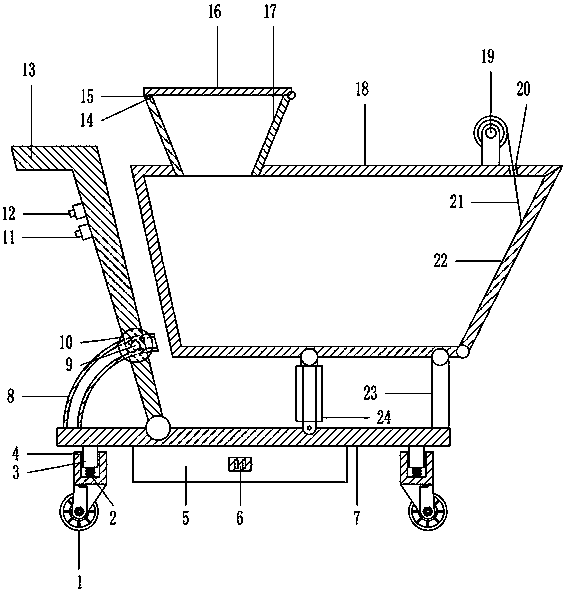

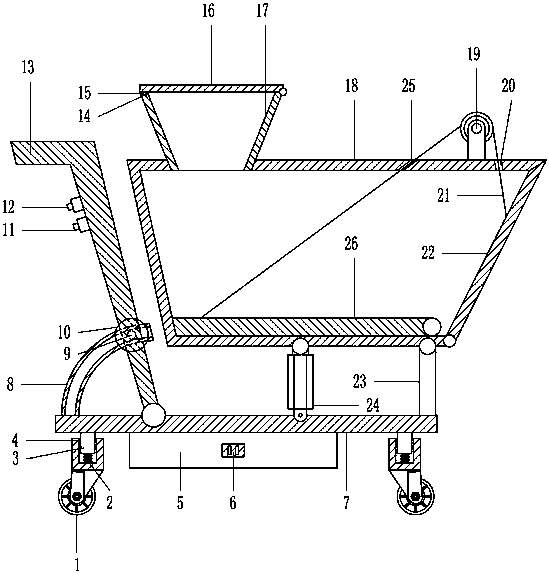

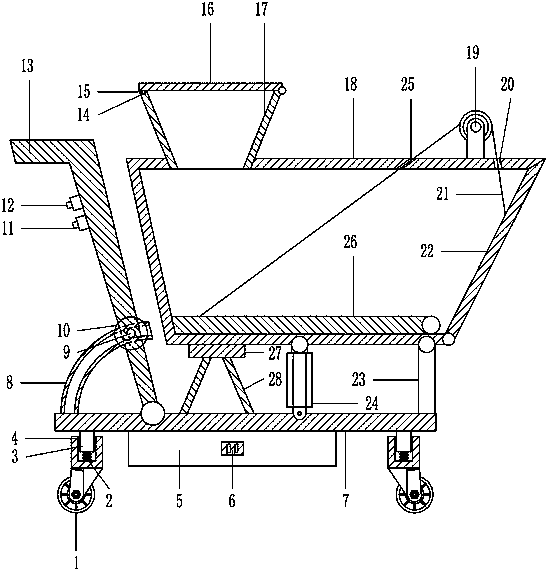

[0032] Referring to accompanying drawing, a kind of material dumping device for building construction, as Figure 1-6 As shown, it includes a wheel 1, an elastic member 2, a support rod 3, a guide rod 4, a battery 5, a charging port 6, a mounting plate 7, an arc frame 8, a butterfly bolt 10, a first button switch 11, and a second button Switch 12, handle 13, block 15, cover plate 16, feed hopper 17, charging frame 18, electric reel 19, first guide sleeve 20, pull wire 21, material blocking plate 22, support column 23 and electric push Rod 24; wheel 1 is affixed to the bottom of guide rod 4; support rod 3 is affixed to the bottom of mounting plate 7, and is slidably connected to guide rod 4, and is connected to the inner bottom of guide rod 4 through elastic member 2; battery 5 is installed on The bottom of the mounting plate 7; the charging port 6 is installed on the front side of the battery 5 and is electrically connected to the battery 5; the arc frame 8 is fixed on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com