Fry rearing device for large-scale family rearing

A seedling raising device and family technology, which is applied in the field of aquaculture equipment, can solve the problems of cross-infection of diseases, cumbersome hatching and cultivation of family seedlings, confusion of seedlings between families, etc., and achieve the effects of simple operation, avoiding cross-infection, and reducing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

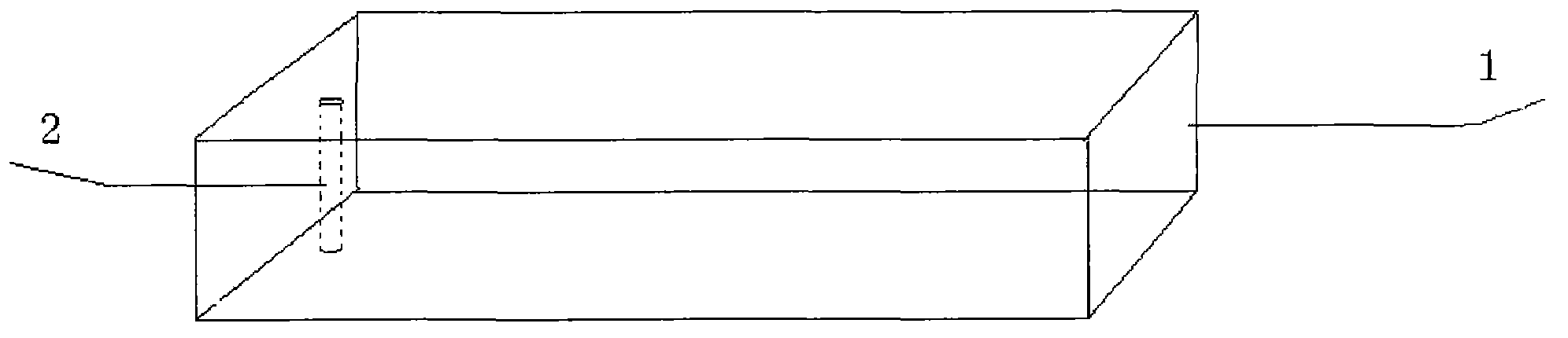

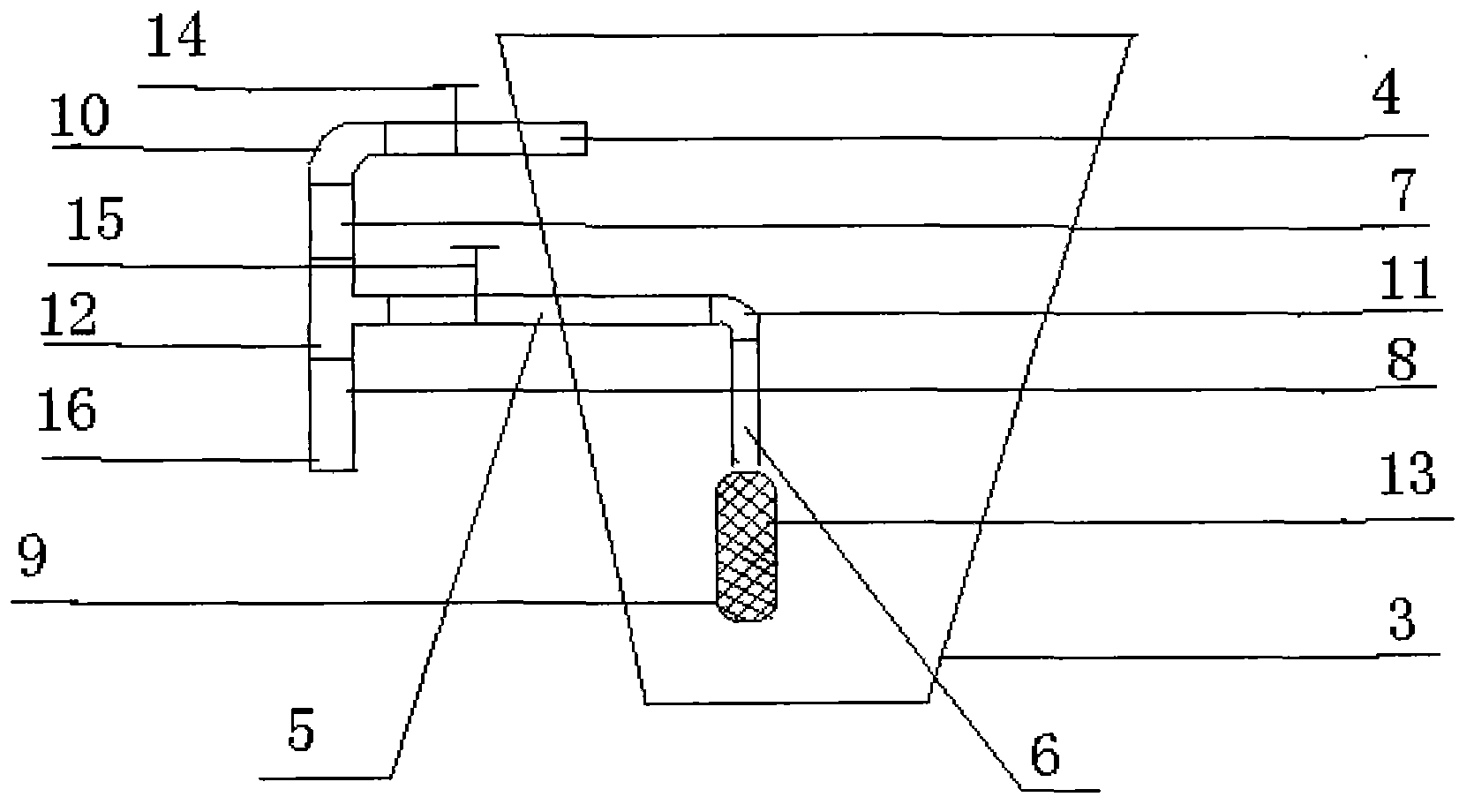

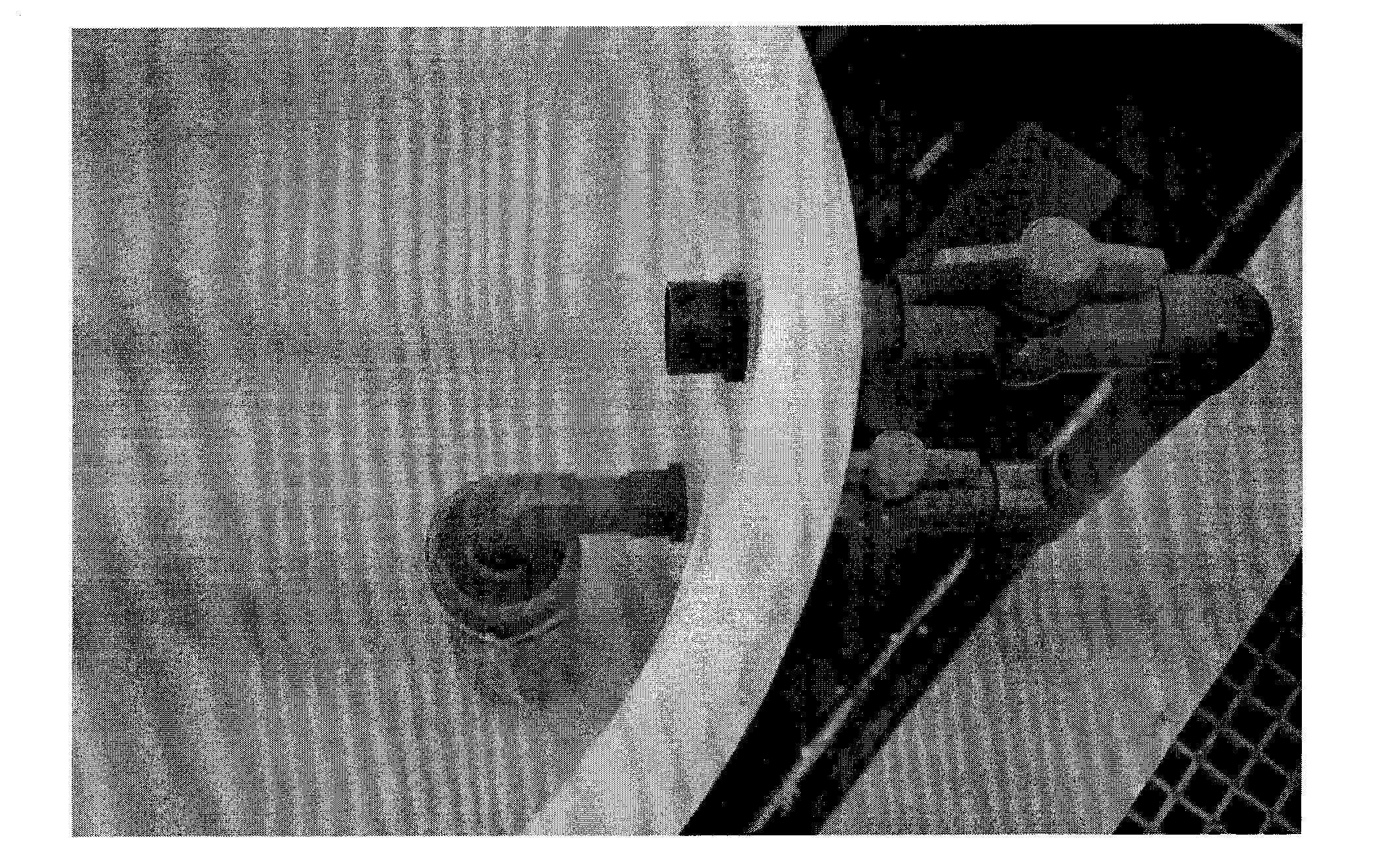

[0015] A seedling raising device for large-scale family cultivation, comprising a thermal insulation tank 1 (see figure 1 ) and the hatching and cultivating barrel discharged in the thermal insulation water tank 1 (see the structural diagram figure 2 , see in kind image 3 ), the water level control drain pipe 2 is housed in the heat preservation water tank, the water level control drain pipe 2 is vertically inserted in the bottom of the heat preservation water tank 1, the upper end of the water level control drain pipe 2 is lower than the height of the heat preservation water tank 1, and the hatching cultivation bucket is composed of the barrel body 3 and installed on the The pipe fittings on the barrel are composed of pipe fittings including overflow pipe 4, upper water suction pipe 5, lower water suction pipe 6, upper drain pipe 7, lower drain pipe 8, water suction drum 9, elbow a10, elbow b11 and tee pipe 12. The water pipe 4 is sealed and connected with the upper drain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com