Chemical barrel pouring device

The technology of a material pouring device and chemical barrel is applied in the field of chemical barrel pouring device, which can solve the problems of low safety factor, large manpower, large waste, etc., and achieve the effects of reducing waste, improving work quality, and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

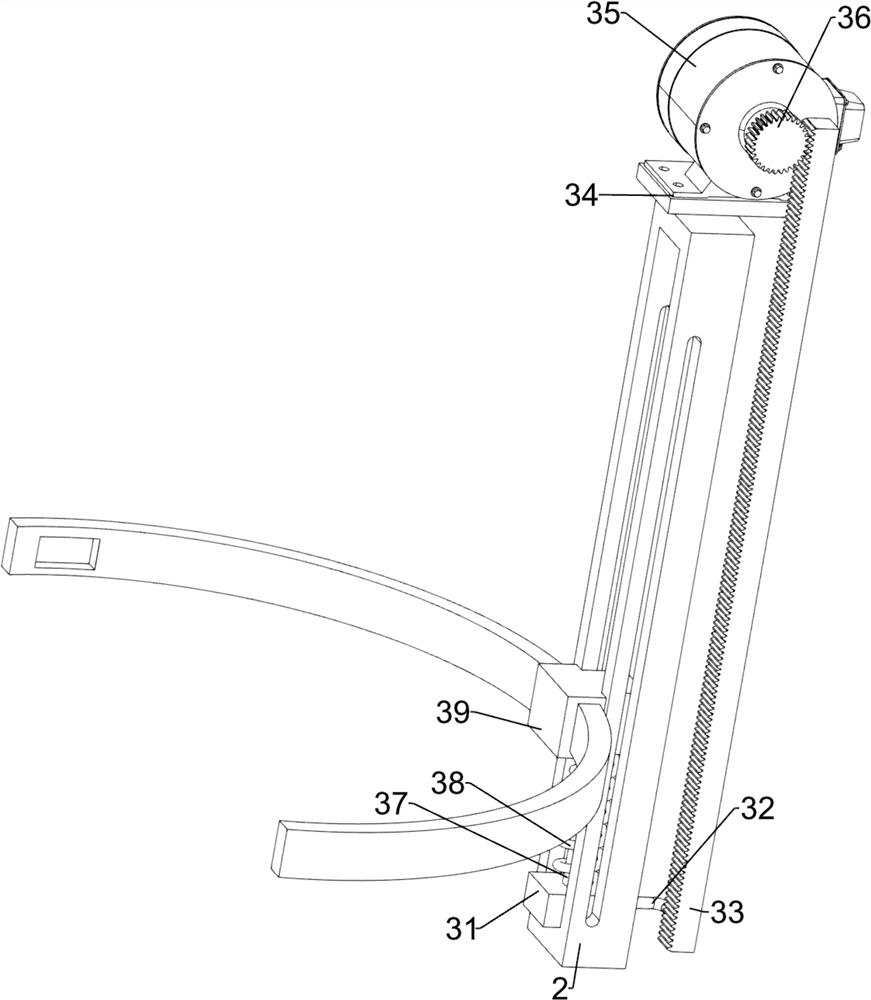

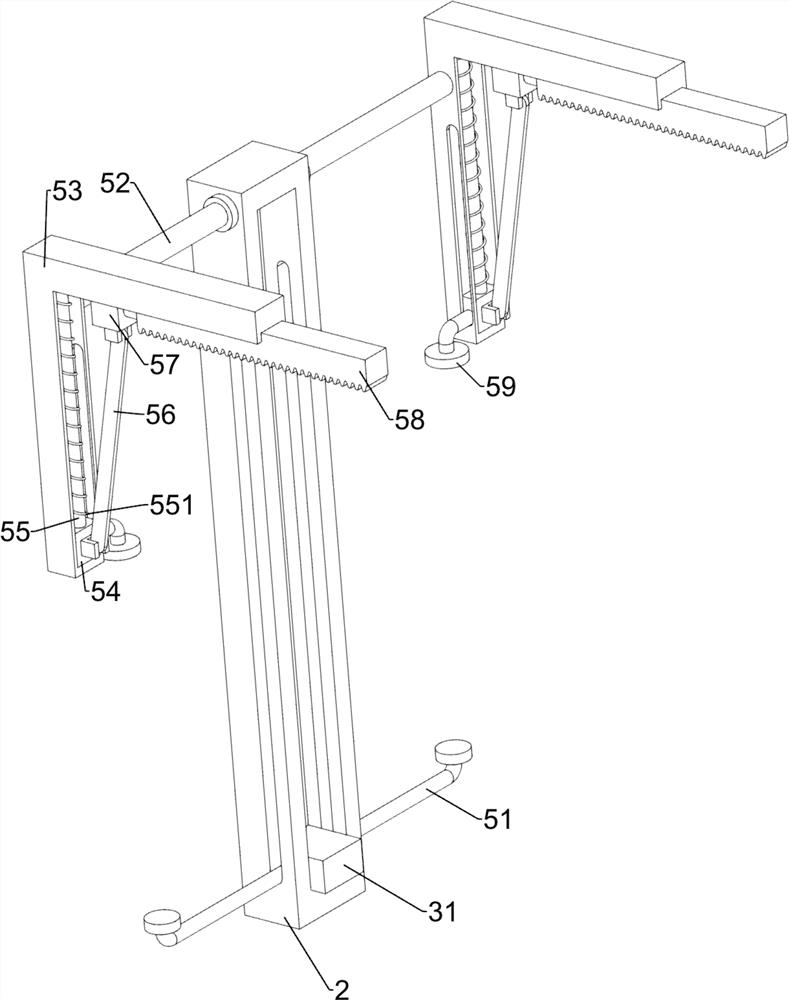

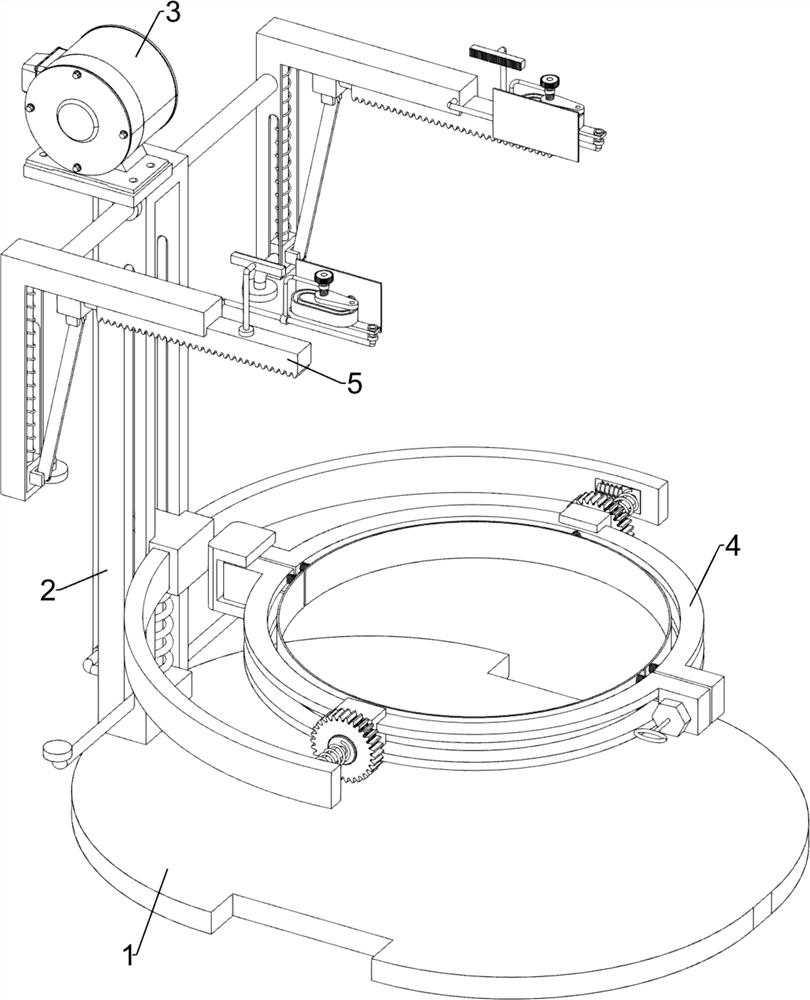

[0022] A chemical tank dumping device, such as Figure 1-6 As shown, it includes a base plate 1, a support frame 2, a lifting mechanism 3, a fixing mechanism 4 and a rotating mechanism 5. The base plate 1 is provided with a support frame 2, and the support frame 2 is provided with a lifting mechanism 3 that lifts and lowers by rotating. The lifting mechanism 3 is provided with a fixing mechanism 4 which is fixed by rotation, and the support frame 2 is provided with a rotation mechanism 5 which is rotated by sliding.

[0023] When using this device to unload chemical barrels, the staff will fix the chemical barrels that need to be unloaded through the fixing mechanism 4. After the fixing is completed, the lifting mechanism 3 will drive the chemical barrels to rise. When the chemical barrels rise to a certain height, The staff drives the chemical barrel to rotate through the rotating mechanism 5, so as to discharge the material. After the completion, the staff controls the rotat...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 and image 3 As shown, a handle 6 is also included, and the front side of the bolt 491 is welded with the handle 6 .

[0032] When fixing the chemical barrel, the staff turns the handle 6 to drive the bolt 491 to rotate, thereby moving the clamping block 44 outward through the nut 49, then puts the chemical barrel between the two clamping blocks 44, and then turns the handle 6 to drive the bolt 491 reversal fixes the chemical barrel, so it is more convenient for people to use by twisting the handle 6.

[0033] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a second connecting frame 7, a third rack 8, a third connecting frame 9, a special-shaped block 10, a fourth connecting frame 11, a third gear 12, a rotating rod 13, a second torsion spring 14, a second Five springs 15 and push plate 16, the second rack 58 is welded with the second connecting frame 7, the top of the second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com