Gantry rail car for bearing double beams

A track-type, trolley technology, applied in the direction of walking bridge cranes, load suspension components, traveling mechanisms, etc., can solve the problems of failing to meet the requirements of fast, accurate and stable, low motion stability, etc., and achieve accuracy and stability The effect of improved performance, increased motion stability, and improved positional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

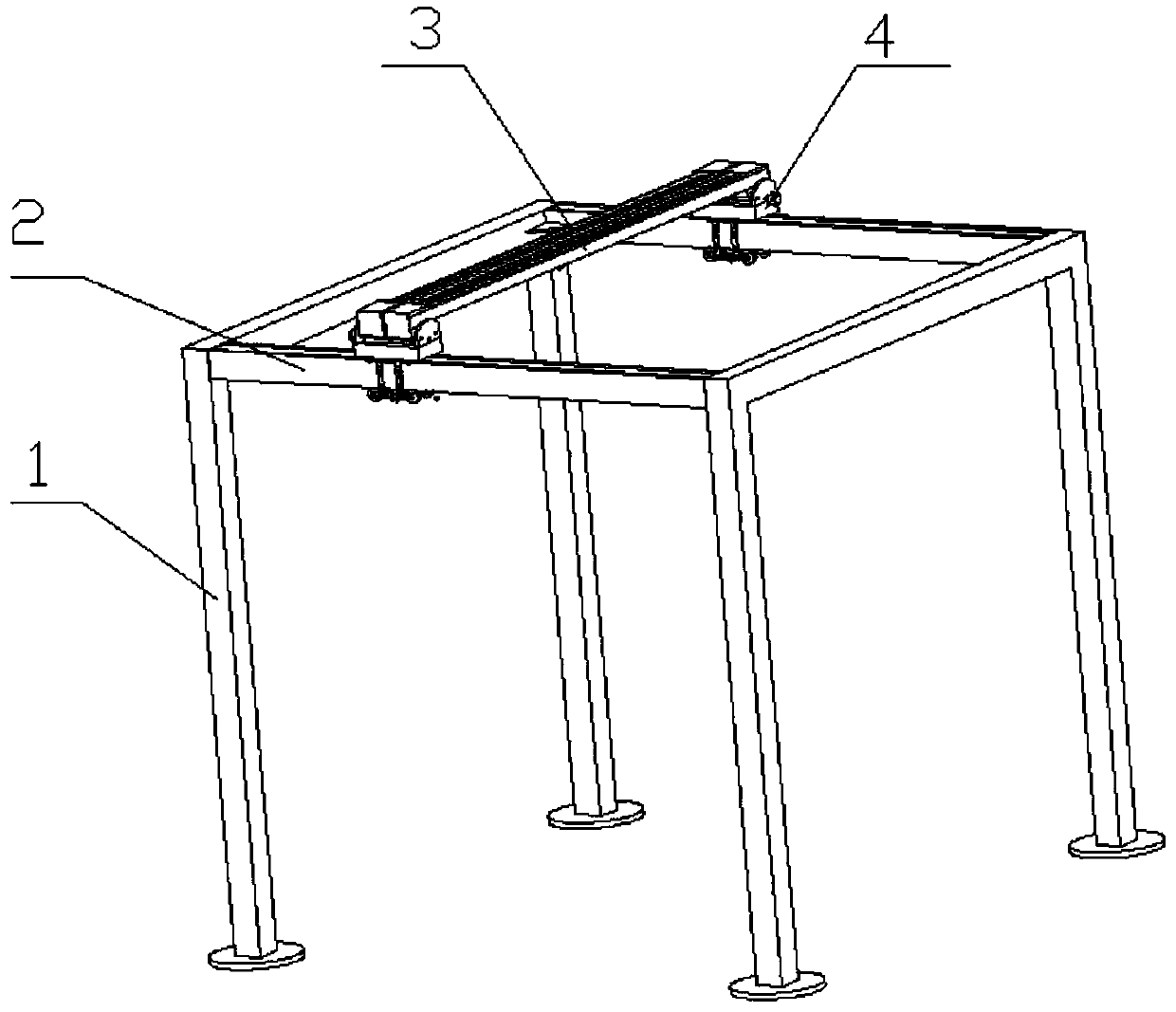

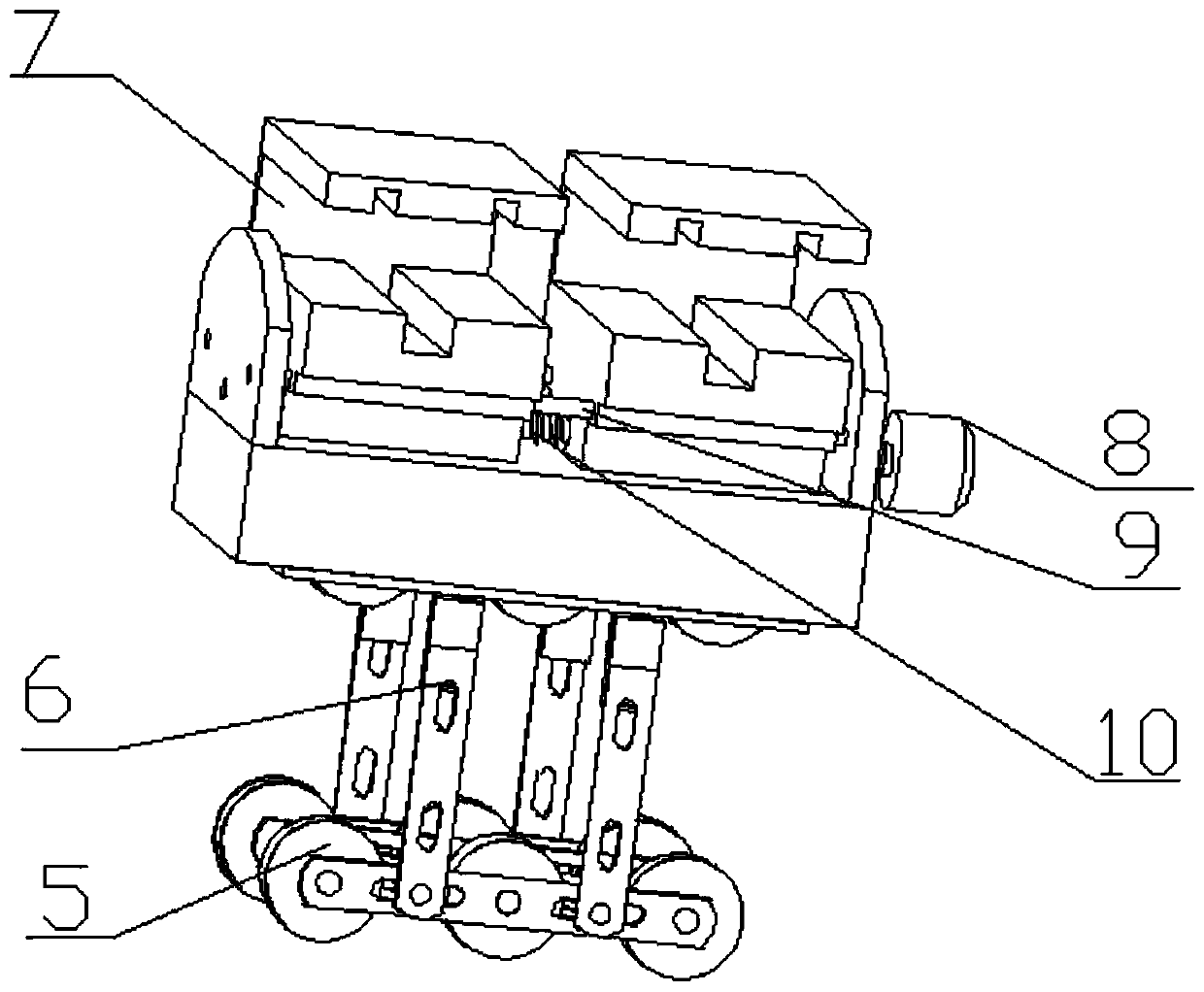

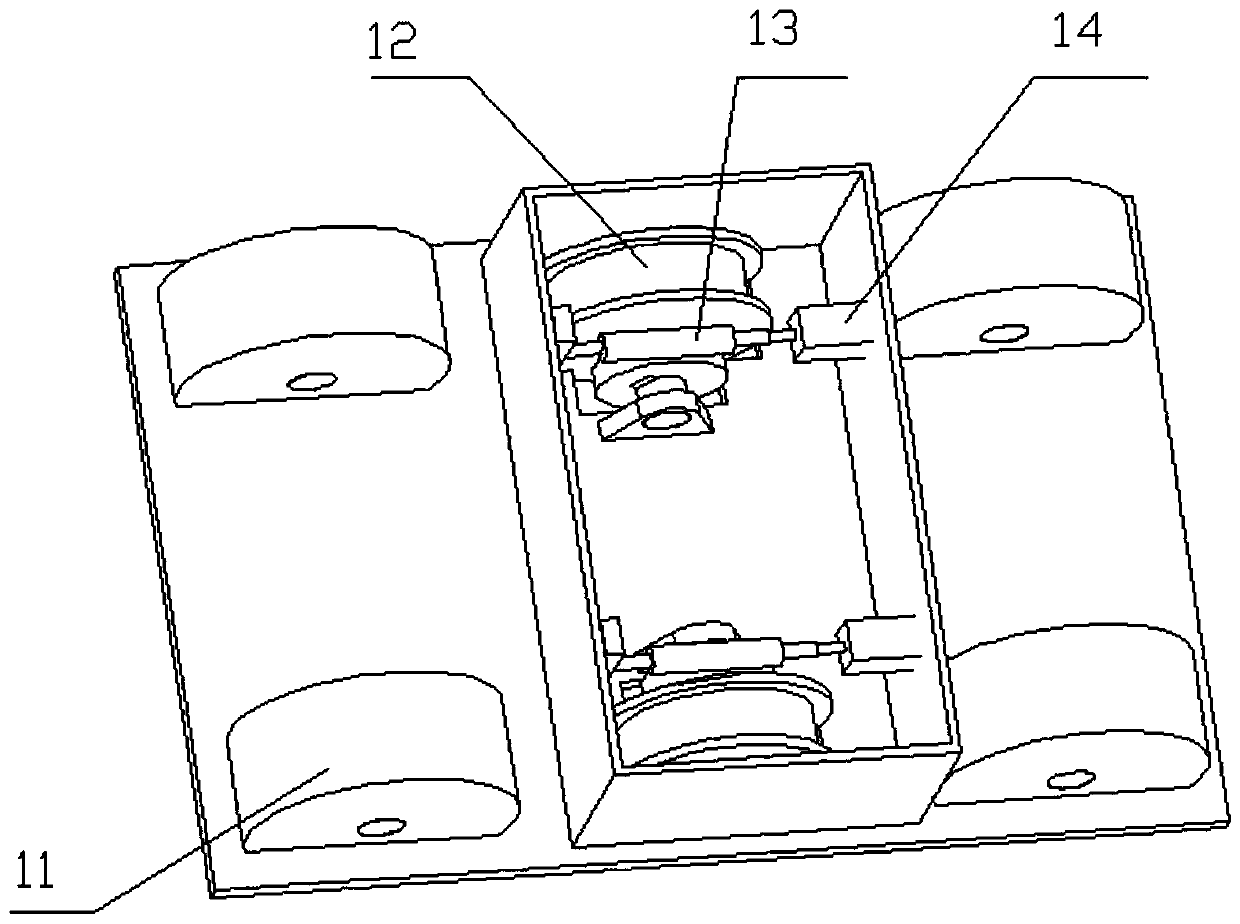

[0014] The specific implementation scheme of the present invention is that two rail trolleys are used to carry and connect double beams to move on the gantry rail. The driving wheel drives the whole trolley through the motor and the reducer. The upper screw moving platform of the car body is connected to carry double beams, and the lower row of wheels is fixed on the guide rails through spring slide rails, so that the beams can achieve fast and stable longitudinal movement on the gantry. move.

[0015] The present invention is a gantry track trolley for carrying double beams, comprising a gantry frame 1, two trolley tracks 2, two beams 3, two track trolleys 4, and a trolley carrying mobile platform 7 connected to the double beams 3 , Four concave bearing wheels 11, two driving wheels 12, two motors 14, two sets of worm gear reducers ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap