Self-lubricating gear

A self-lubricating, gear technology, applied in the direction of engine lubrication, gear lubrication/cooling, belt/chain/gear, etc., to achieve the effect of easy production, simple structure, good lubrication and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

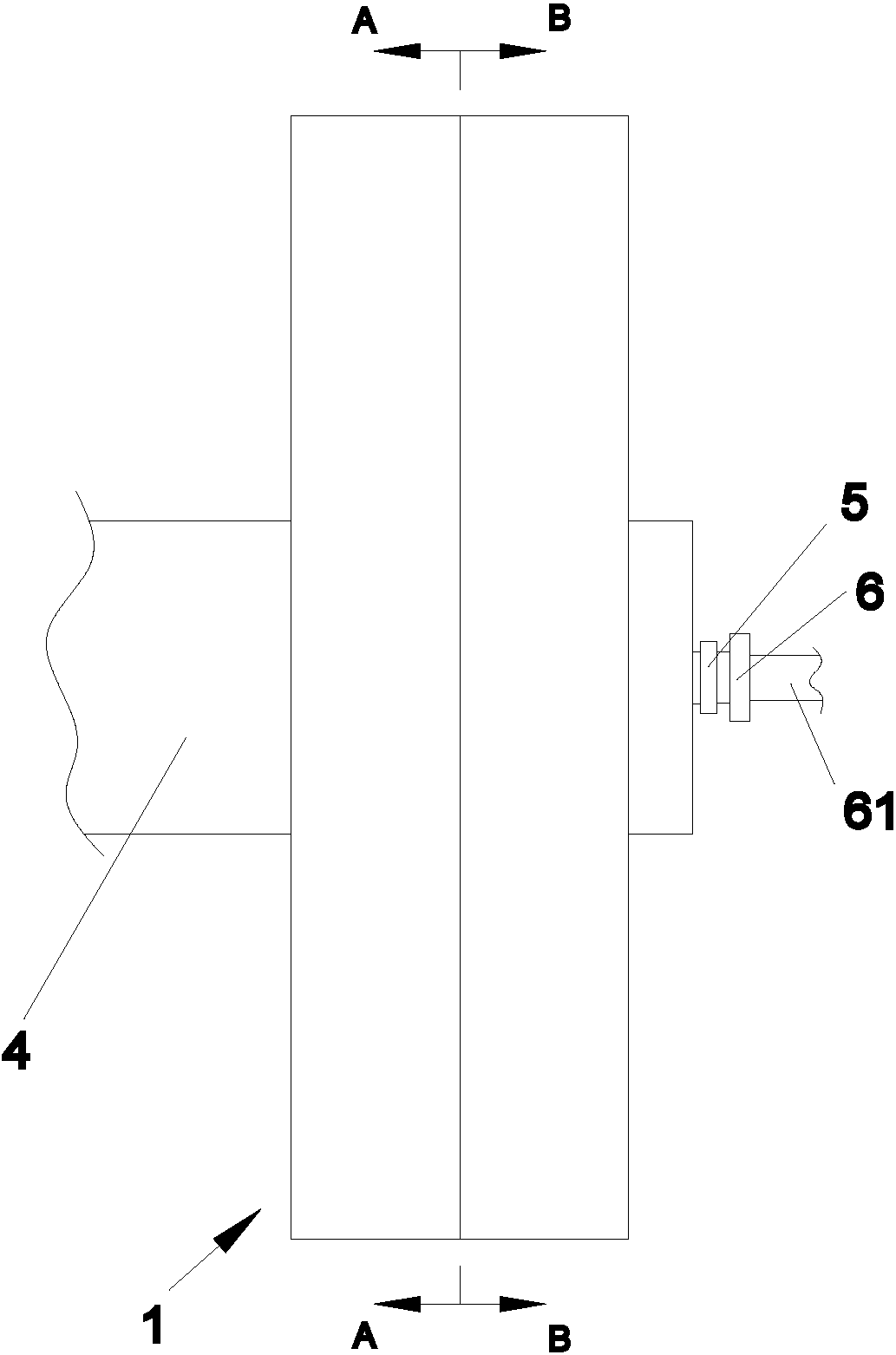

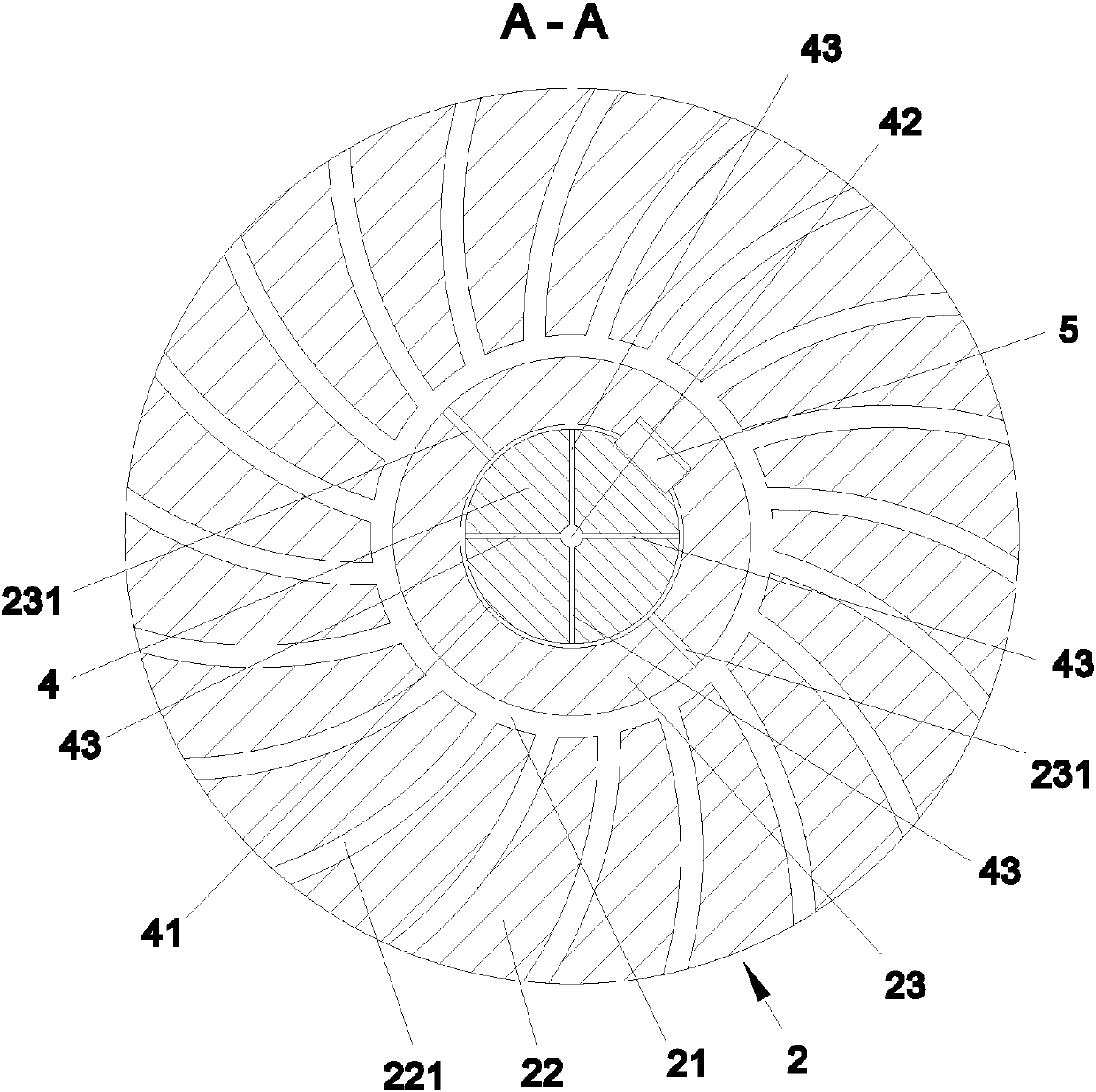

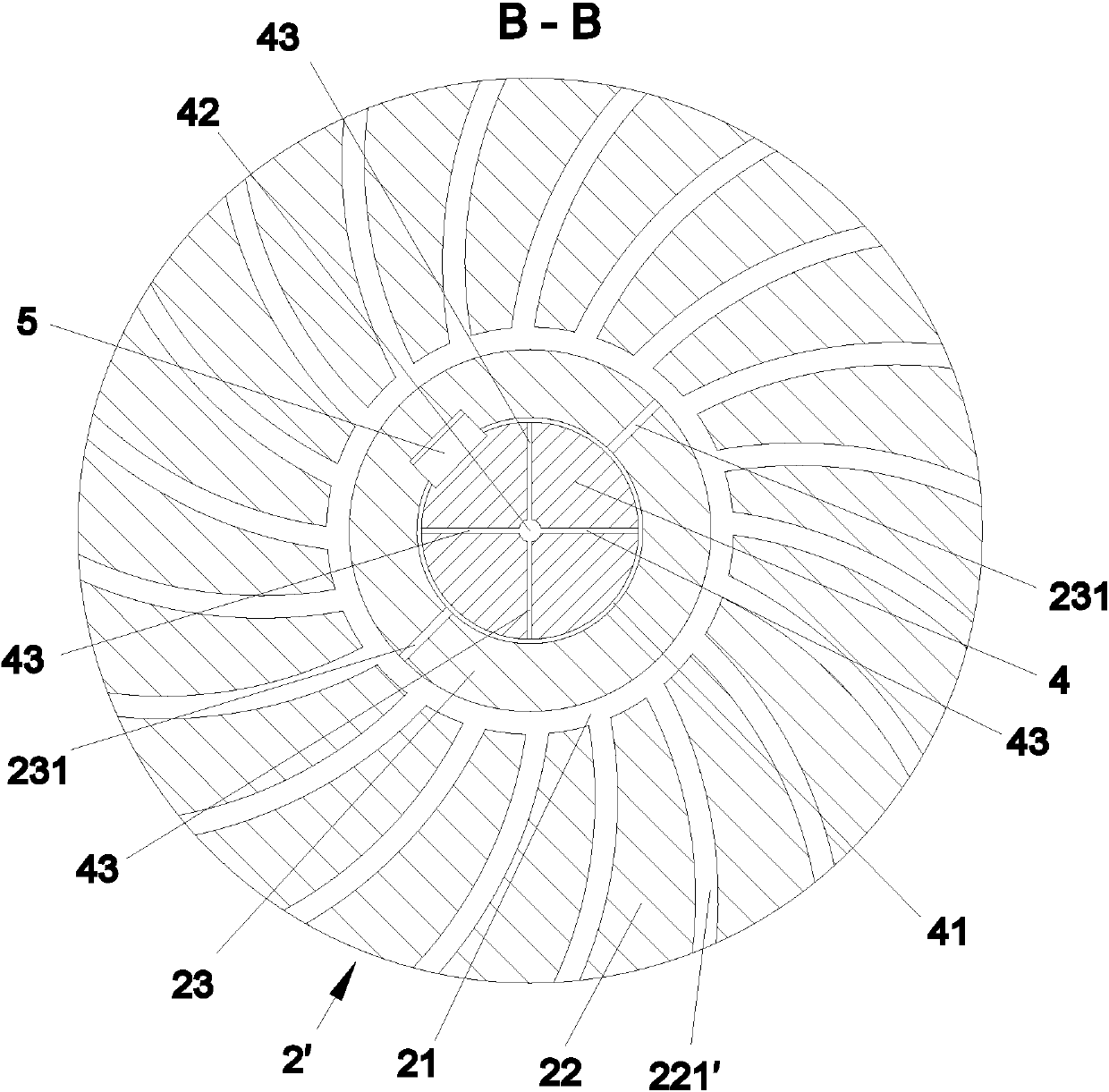

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: figure 1 to attach image 3 As shown, a self-lubricating gear includes a gear part 1, and a rolling shaft 4 is arranged in the center of the gear part 1. The gear part 1 is composed of two toothed discs with the same material. The toothed discs shown It is divided into a toothed disc 2 and a second toothed disc 2'. The circular end surface of the first toothed disc 2 is provided with an inner ring groove 21, and the inner ring groove 21 is connected with several arc-shaped guide grooves radiating to the outer circular surface. 221, the outlet of the arc guide groove 221 is located at the root of the tooth, the inner ring groove 21 is connected with an outer oil pipe 231, and the outer oil pipe 231 is symmetrically arranged and leads to the inner circular surface; the rolling shaft 4. The outer circular surface is provided with an outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com