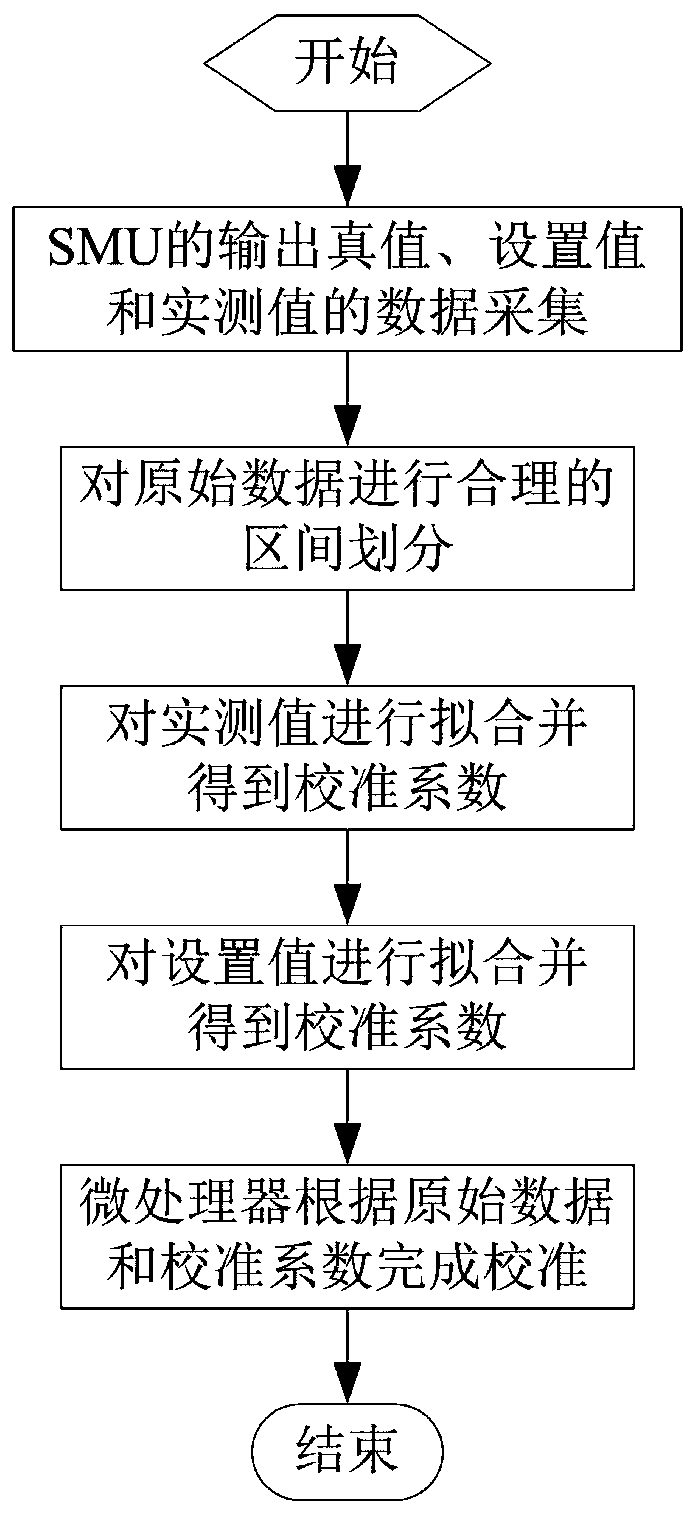

Novel calibration method for high-precision source-meter integrated measuring equipment

A technology of measuring equipment and calibration method, which is applied to measuring devices, measuring electrical variables, complex mathematical operations, etc., can solve the problems of large calculation amount, unstable system, poor practicability, etc., and achieves easy implementation, small calculation amount, and applicability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The following takes the voltage of the SMU as the calibration object, and describes the specific implementation method in the range of 100-1000V under the condition of 50Hz.

[0029] The following table is the raw data obtained:

[0030] Table 1

[0031]

[0032] First, the measured value of the SMU is calibrated, and the calibration expression is obtained by using the nonlinear least square method through formula (1):

[0033] X'=-9.4847*10 -11 *X 3 +1.91653913*10 -7 *X 2 +0.999189812*X-0.0992891821 (3)

[0034] Substitute the measured value X of the SMU before calibration to get the measured value X' after calibration.

[0035] Then the setting value of the SMU is calibrated, and the calibration expression is obtained by using the nonlinear least square method through formula (2):

[0036] Z'=-4.394824*10 -9 *Z 3 +6.63190422*10 -6 *Z 2 +0.998267961Z+0.183169069 (4)

[0037] Substitute the setting value Z of the SMU before calibration to get the setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com