Microwave resonant cavity and electron paramagnetic resonance probe using same

An electron paramagnetic resonance and microwave resonant cavity technology, applied in the field of microwave resonant cavity and electron paramagnetic resonance probe, can solve the problems of poor coupling ability of low-frequency modulation field, low Q value, single coupling structure and function, etc., and achieve strong coupling ability. , the effect of improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

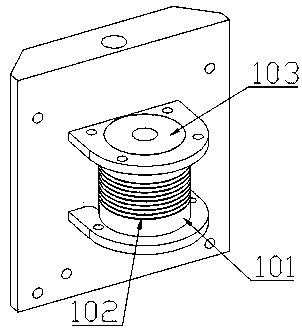

[0026] A microwave resonator 1 with low-frequency modulation field coupling capability, such as figure 1 shown, including vertically arranged ring-shaped sapphire crystals ( figure 1 not shown) and a metal sleeve 101 sleeved on the outside of the ring-shaped sapphire crystal, and a plurality of slits 102 are provided on the metal sleeve at equal intervals horizontally. The ring-shaped sapphire crystal preferably has an outer diameter of 10 mm, an inner diameter of 5 mm, and a height of 13 mm; preferably 10 gaps, each with a height of 0.18 mm, and the distance between two adjacent gaps is 1 mm.

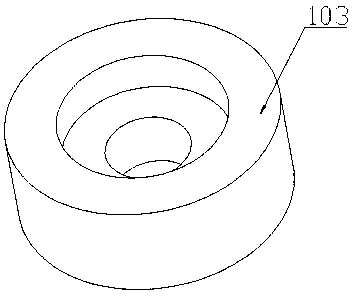

[0027] The upper and lower sides of the ring-shaped sapphire crystal are limited and fixed by the Teflon gasket 103 with internal steps to ensure that the ring-shaped sapphire crystal is stably arranged inside the metal sleeve, and the size of the steps matches the size of the ring-shaped sapphire crystal. Teflon gasket structure such as figure 2 shown. Teflon has a small dielectri...

Embodiment 2

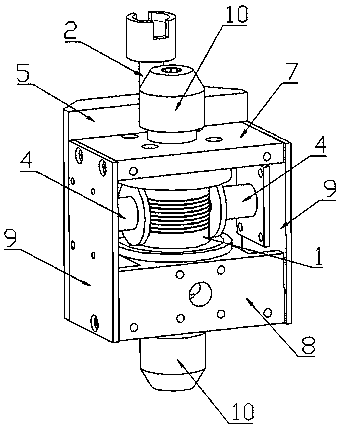

[0030] An electron paramagnetic resonance probe, such as Figure 3-5 As shown, it includes the microwave resonant cavity 1 described in Embodiment 1, a tuning unit fixedly connected to the microwave resonant cavity, and a coupling unit between the tuning unit and the microwave resonant cavity. The side is provided with a Helmertz coil 4, and the Helmertz coil 4 is composed of a horizontally fixed coil fixing mechanism and an enameled wire coil wound thereon, and the coil fixing mechanism is made of an insulating material; the microwave resonator 1 and the Helmhertz coil 4 are enclosed in the housing.

[0031] Specifically, in this embodiment, the size of the annular sapphire crystal is 10mm in outer diameter, 5mm in inner diameter, and 13mm in height; the size of the metal sleeve is 18mm in outer diameter, 16mm in inner diameter, and 16mm in height; the enameled wire coil is preferably made of enameled wire with a diameter of 0.51mm It is made by winding 110 turns on the coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap