Clearing device, photoetching apparatus and photoetching method

A technology of cleaning device and lithography equipment, applied in microlithography exposure equipment, optomechanical equipment, photolithography process exposure device, etc., can solve the problem of grating panel being difficult to clean, and reduce the probability of wiping or replacing grating panel, The effect of reducing secondary pollution, improving convenience and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

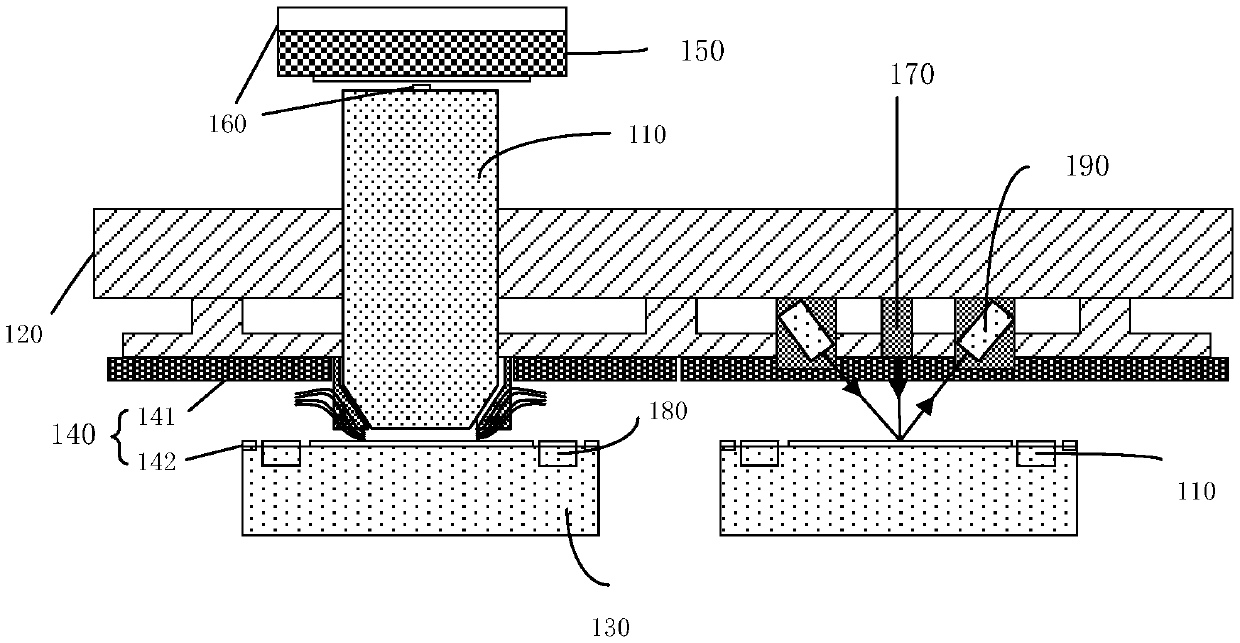

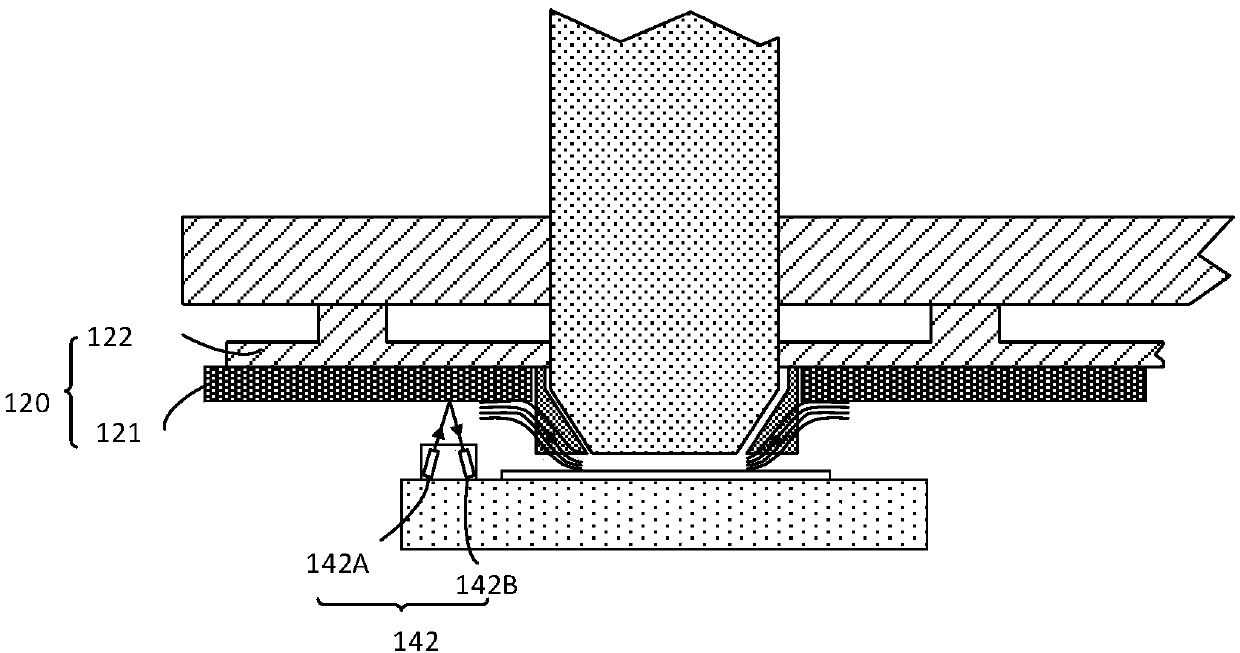

[0043] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

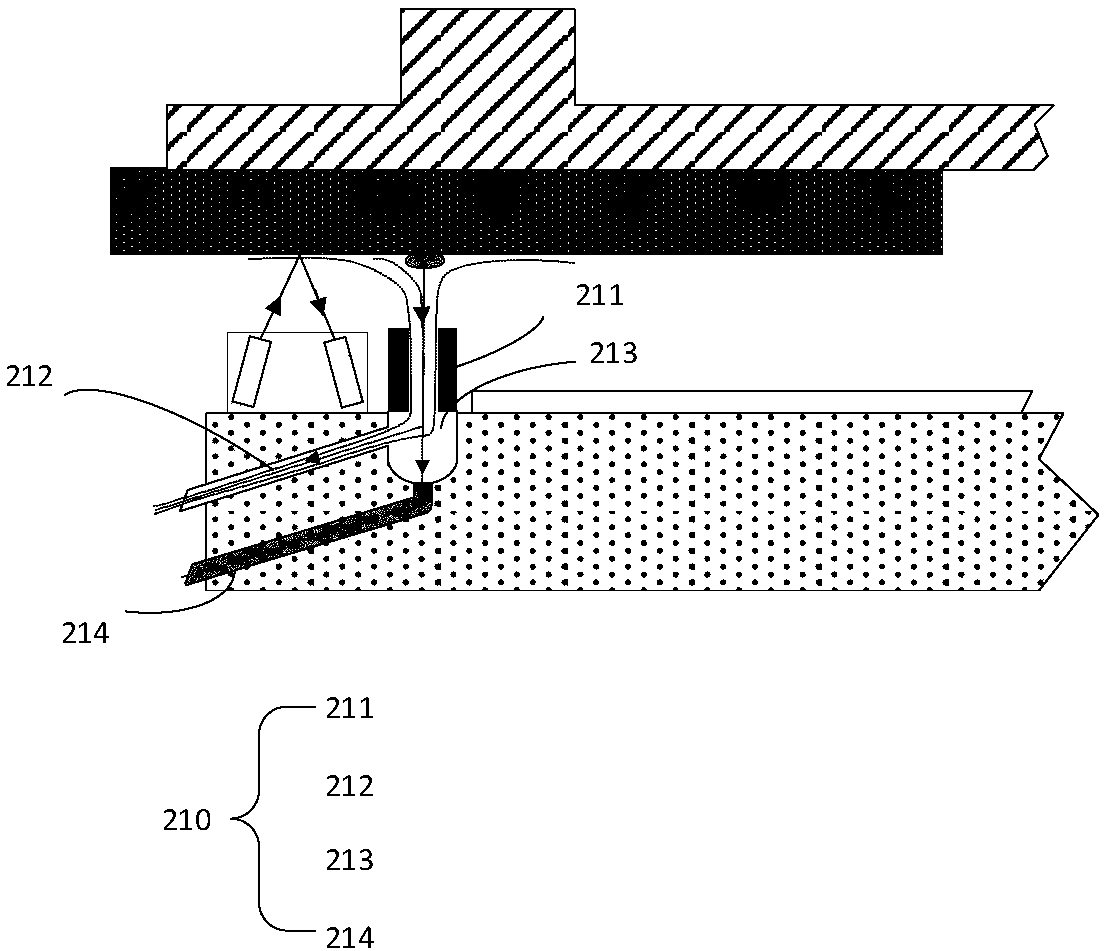

[0044] refer to Figure 3 to Figure 5, the present invention provides a cleaning device 210, the cleaning device 210 includes: an adsorption unit 211 and a negative pressure channel 212;

[0045] The adsorption unit 211 is arranged on the surface of a workpiece table facing the bearing surface of the object to be removed, the negative pressure channel 212 is located inside the workpiece table, and the negative pressure channel 212 communicates with the adsorption unit 211 and communicates with the adsorption uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com