A compound processing equipment for non-woven powder cover

A composite processing, non-woven technology, applied in mechanical equipment, material gluing, cosmetic powder containers, etc., can solve problems such as affecting the cleanliness of the powder cover, sticking to the workbench, and artificially applying glue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0027] see Figure 1-Figure 10 , the specific embodiments of the present invention are as follows:

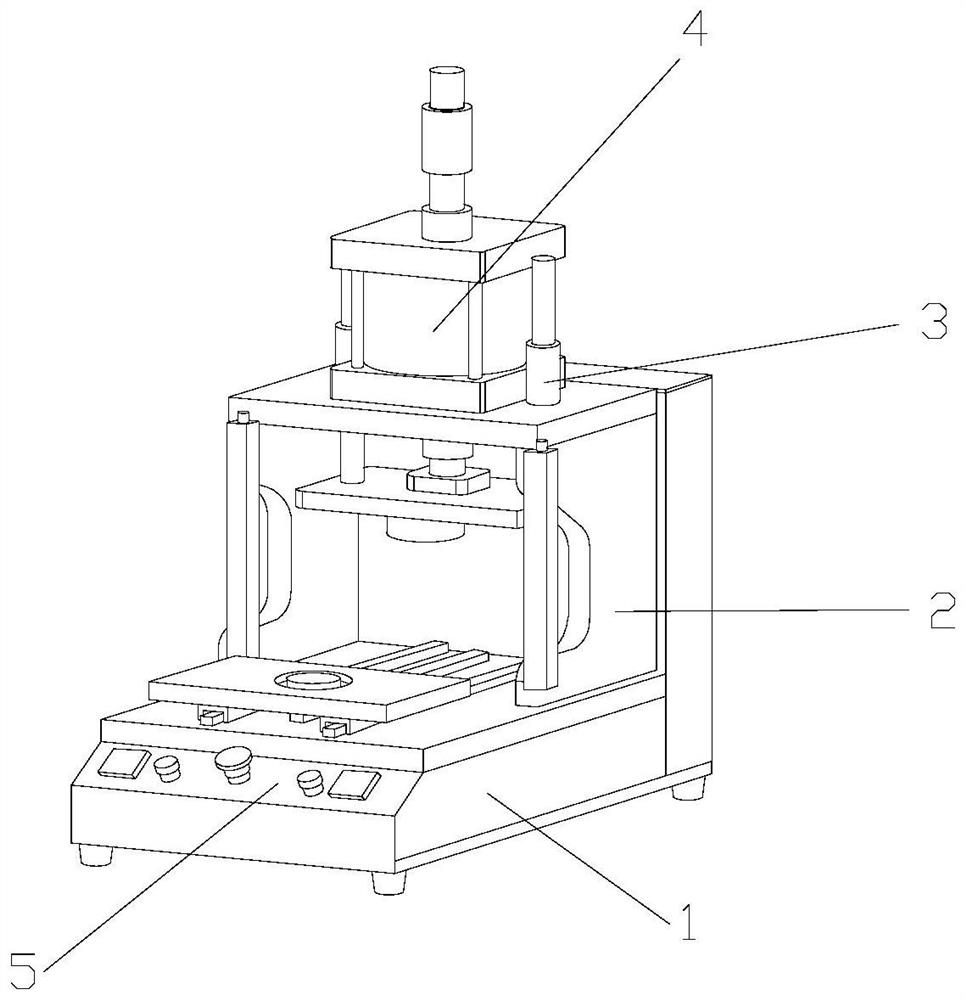

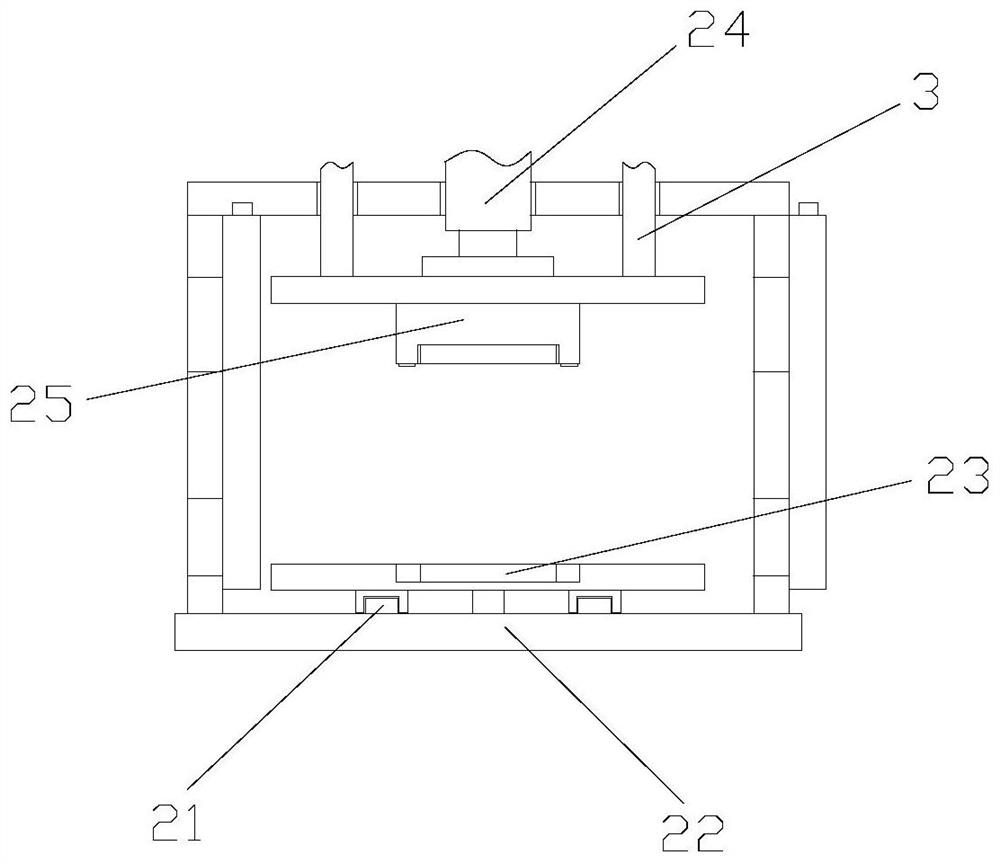

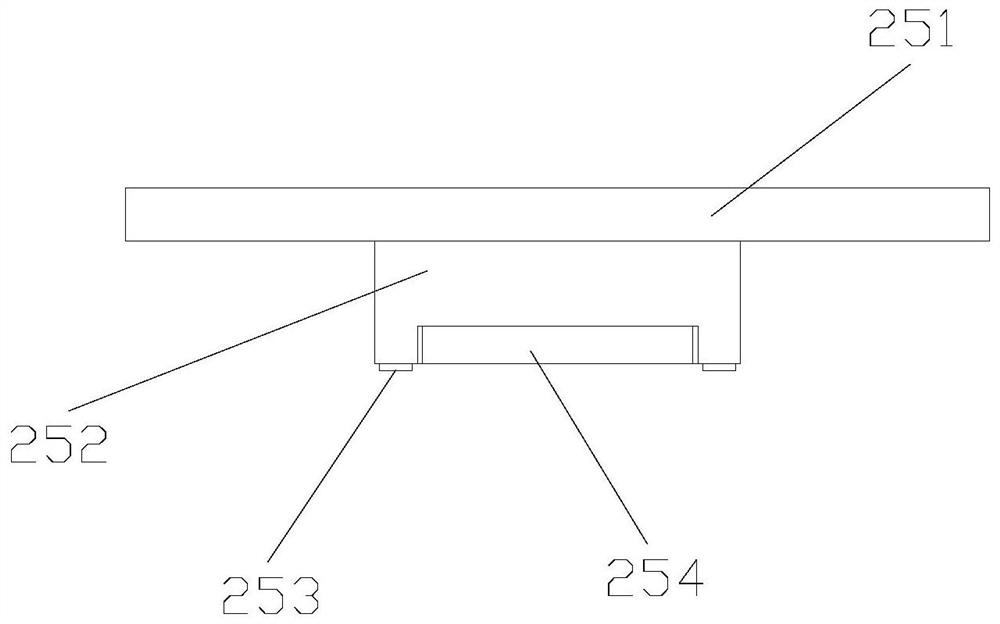

[0028] Its structure includes an underframe 1, a composite structure 2, a guide rod 3, a cylinder 4, and a control panel 5. The composite structure 2 is vertically installed on the upper end of the underframe 1 and is mechanically connected. The guide rod 3 runs through the composite structure 2. The upper end, the cylinder 4 is vertically installed on the upper end of the composite structure 2 and is mechanically connected, the control panel 5 is arranged at the front end of the chassis 1; the composite structure 2 includes a slide rail 21, a frame 22, a placement table 23, a piston Rod 24, press-fit structure 25, described slide rail 21 is horizontally installed on the inner bottom of frame 22, and described placement table 23 is arranged on frame 22 upper end and is connected with slide rail 21 flexibly, and described guide bar 3 is embedded and installed in the frame The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com