Non-contact disassembly detection mutual inductor

A non-contact, transformer technology, applied in the field of transformers, can solve problems such as hidden safety hazards, current transformer damage, equipment damage, etc., and achieve the effect of increasing opening loosening or opening detection, quick disconnection detection, and sensitive magnetic induction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

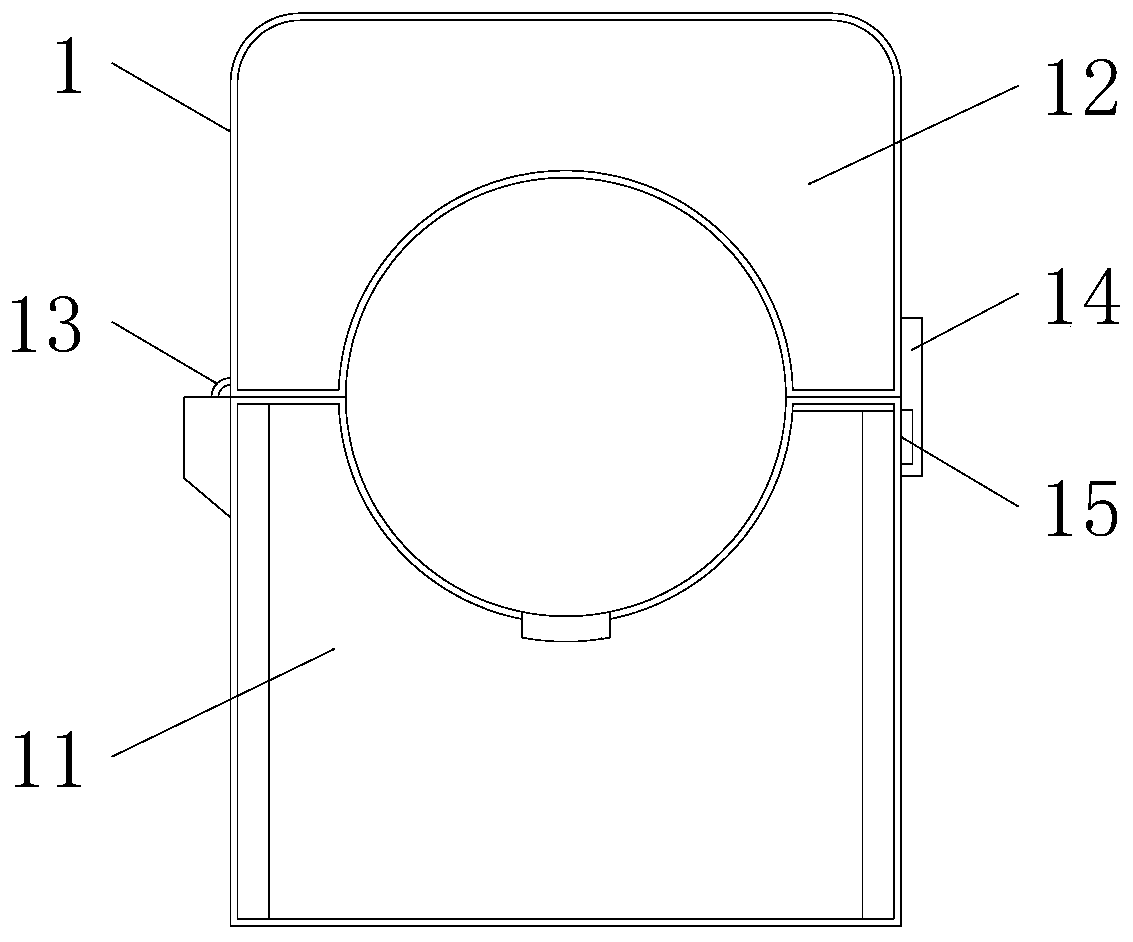

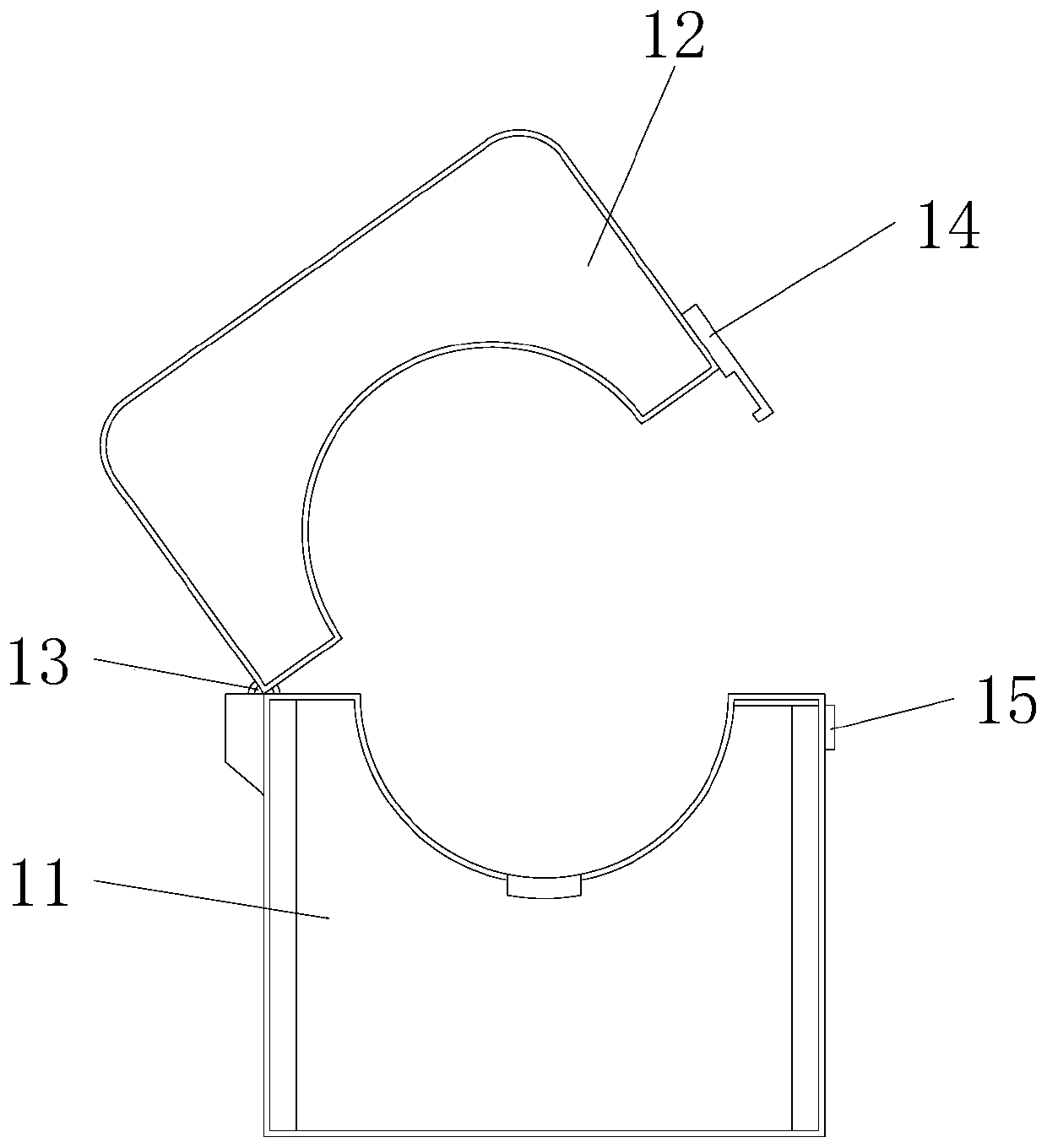

[0024] see Figure 1-2 The present invention provides a non-contact disassembly detection transformer. The transformer 1 includes a cable holder 12 and a cable base 11 arranged up and down. One end of the connection between the cable base 11 and the cable holder 12 is provided with a Hinge 13, the cable base 11 and the cable holder 12 are rotatably connected by the hinge 13, and the end of the conflict between the cable base 11 and the cable holder 12 is symmetrically provided with an arc-shaped cable groove , the cable holder 12 is fixed with a raised buckle 14, the cable base 11 is fixed with a raised buckle locator 15, and the buckle 14 is provided with a groove matching the buckle locator 15, The cable holder 12 and the hinge 13 are fixedly connected by a buckle 14 and a buckle positioning member 15 .

[0025] As an example of the opening and closing of the transformer: the hinge 13 on the top of the cable base 11 is turned over, and the hinge between the cable holder 12 ...

Embodiment 2

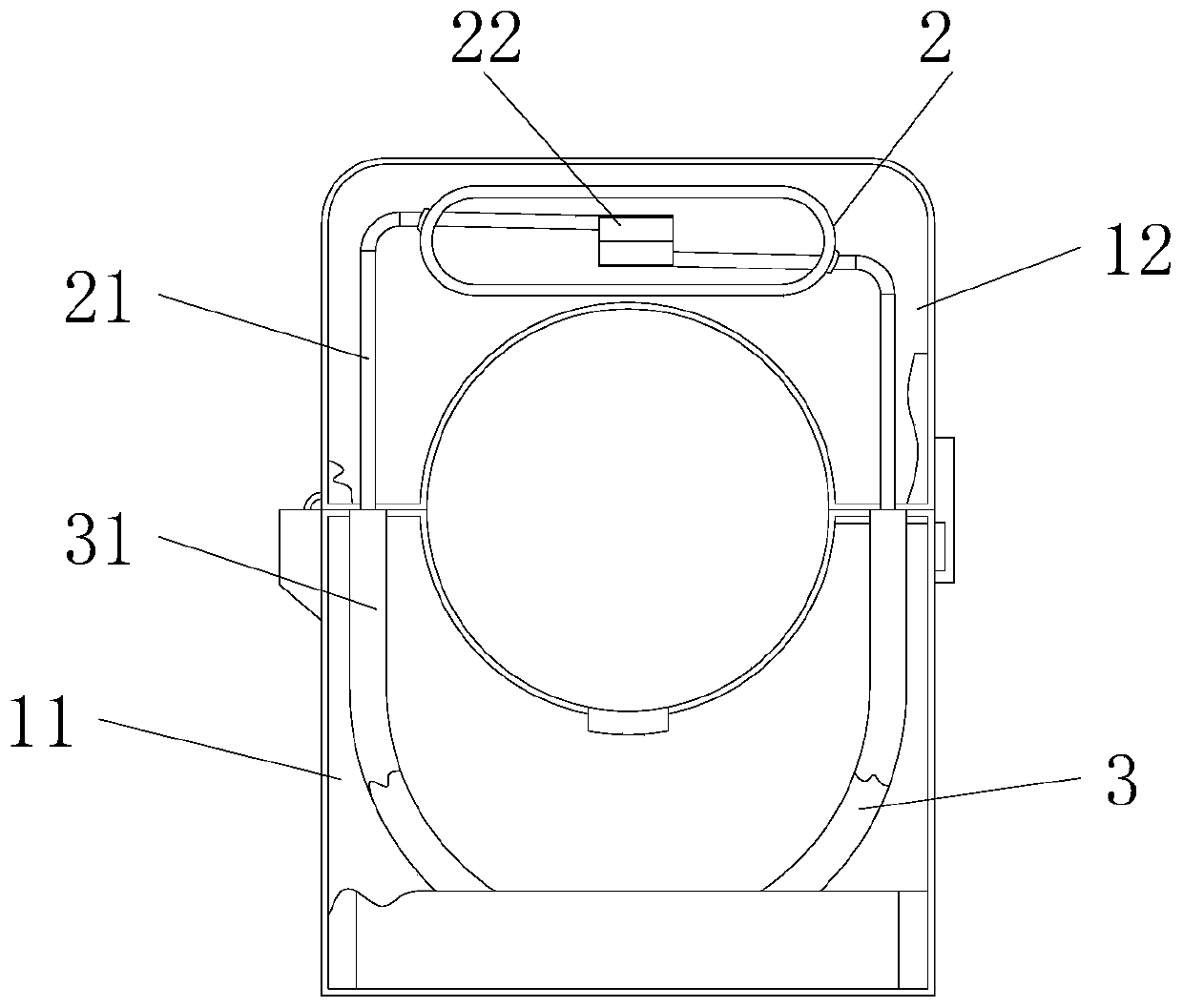

[0027] see Figure 3-4 , the present invention provides a non-contact disassembly detection transformer, a magnet 3 is installed inside the cable base 11, and the two magnetic poles 31 on the magnet 3 both penetrate the upper surface of the cable base 11, symmetrically , a reed switch 2 is installed inside the cable holder 12, and two reeds 21 are arranged inside the reed switch 2, and the close ends of the two reeds 21 are symmetrically connected to a contact part 22, and the reed switch 2 The two reeds 21 both pass through the lower surface of the cable holder 12 .

[0028] It should be noted:

[0029] 1. When the cable base 11 and the cable holder 12 are closed, the end surface of the magnetic terminal post 31 penetrating the cable base 11 and the end surface of the reed 21 penetrating the cable holder 12 are adsorbed, and the reed 21 and the magnetic terminal post 31 During suction, the two contact parts 22 on the two reeds 21 are closed.

[0030] 2. When the cable base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com