Ultrasonic cleaning device for film coated graphite frame

An ultrasonic and cleaning tank technology is applied in the field of cleaning devices for graphite frames for silicon wafer coating, which can solve the problems of long soaking time, large number of turnover graphite frames, and low cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

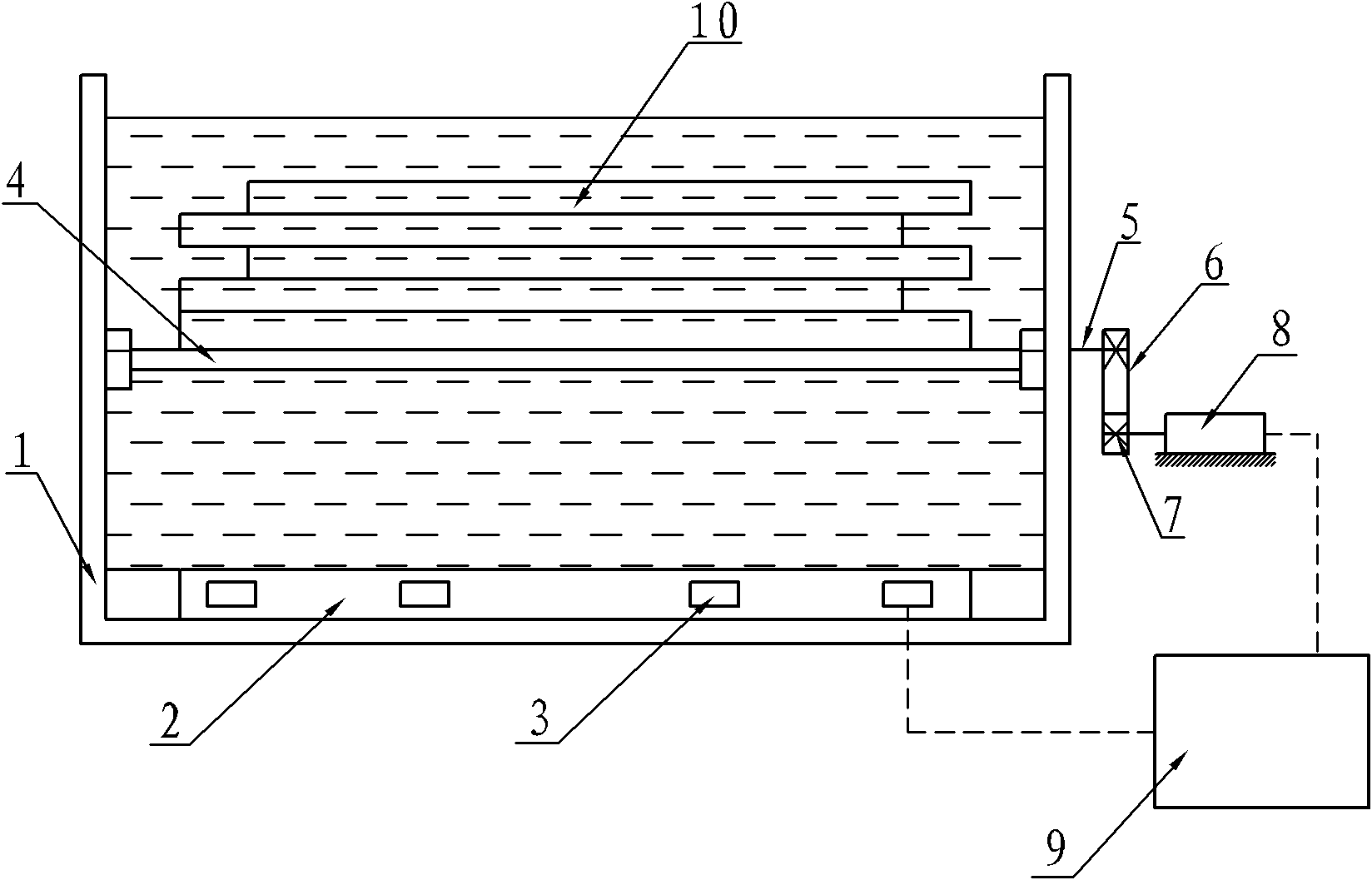

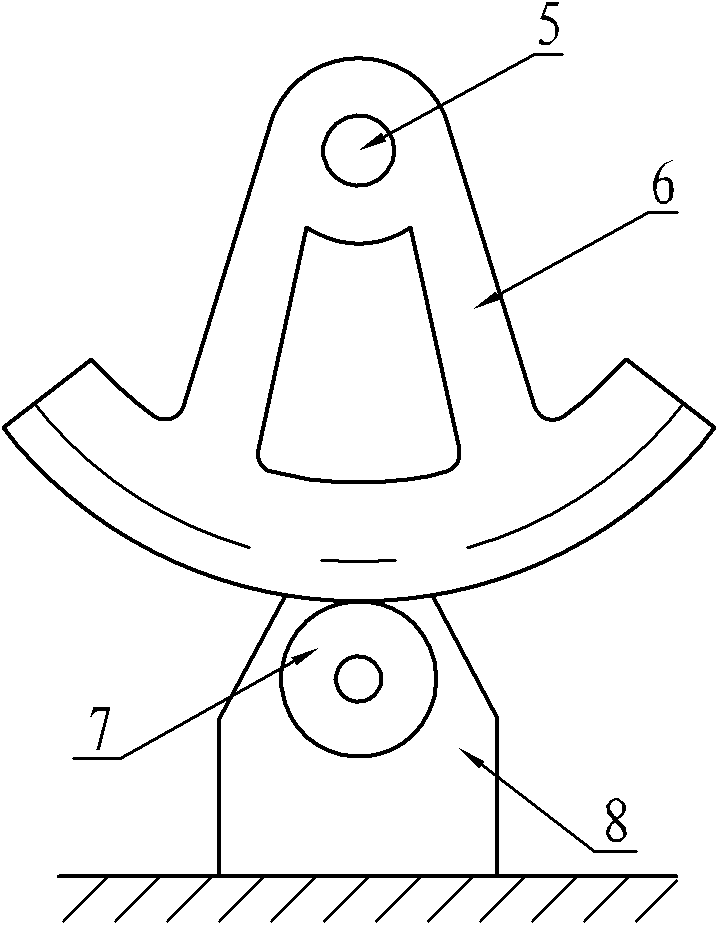

[0012] Such as Figure 1~2 As shown, an ultrasonic cleaning device for a coated graphite frame includes a cleaning tank 1, an ultrasonic vibrator mounting frame 2, an ultrasonic generator 3, a swing bearing frame 4, a supporting shaft 5, an bevel gear 6, a driving gear 7, and a servo motor 8 and the electronic control part 9, the ultrasonic generator 3 is arranged in the ultrasonic vibrator installation frame 2, the ultrasonic vibrator installation frame 2 is arranged at the bottom of the cleaning tank 1, the swing bearing frame 4 is installed in the cleaning tank 1 through the support shaft 5, and the support shaft 5 One end protrudes out of the cleaning tank 1, and a bevel gear 6 is installed on the protruding end of the support shaft 5. The driving gear 7 is installed on the output shaft of the servo motor 8, and the driving gear 7 is meshed with the bevel gear 6. The ultrasonic generator 3 and the servo motor 8 are electrically connected with the electric control part 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com