Cellucotton opener

A cotton opener and fiber technology, which is applied to fiber opening and cleaning machines, opening and cleaning with toothed tools, and opening and cleaning with suction devices, can solve the problem of preheating fiber cotton raw materials, limited cotton mixing effect, and inability to break down The problem of chip and impurity collection, etc., can speed up the loosening speed, improve the processing quality, and be easy to break up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

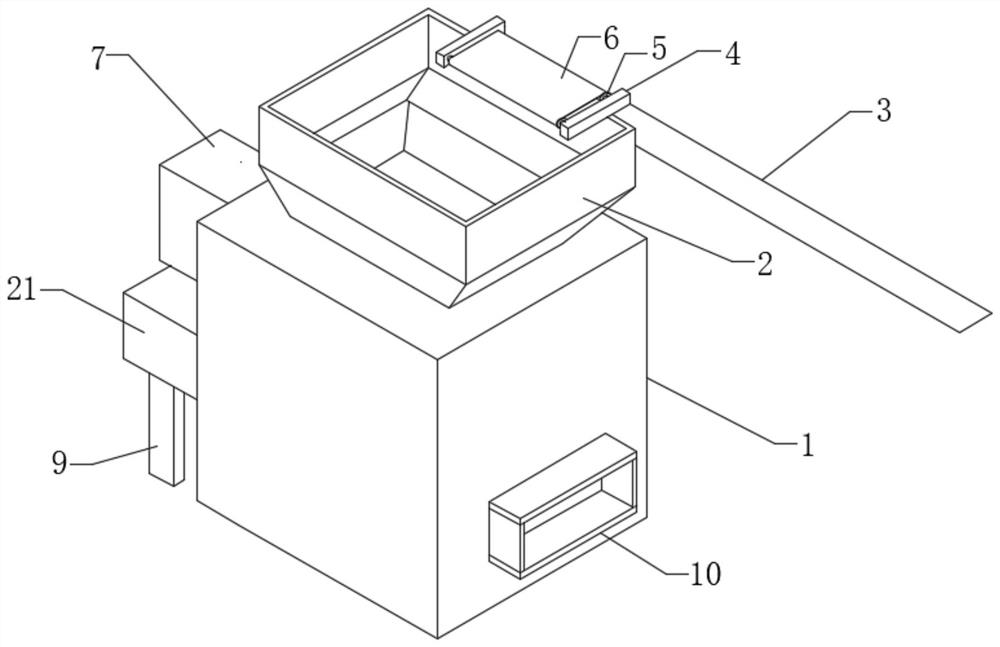

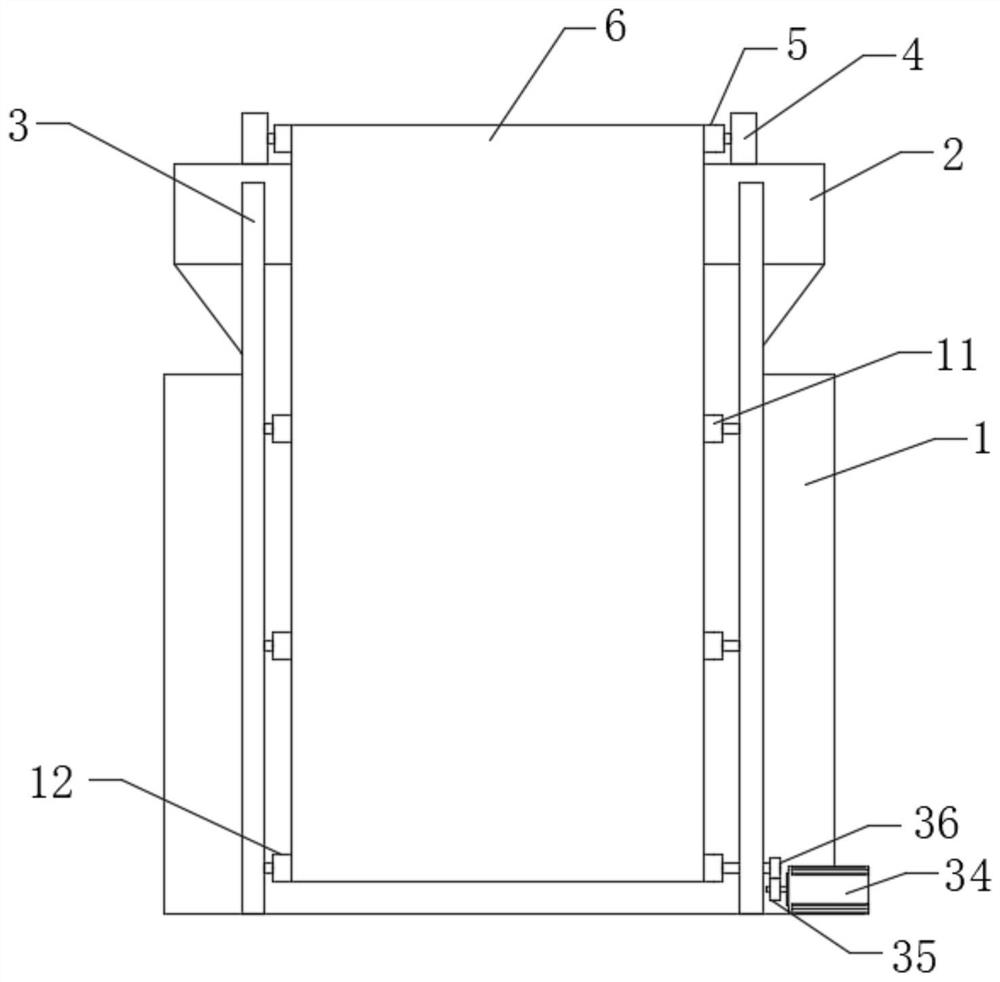

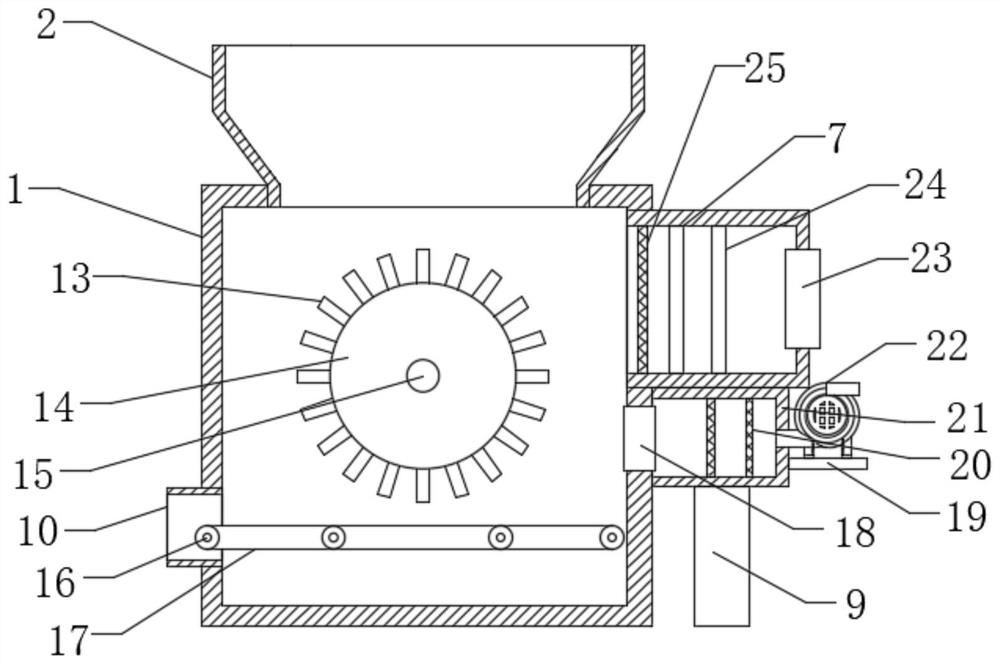

[0021]SeeFigure 1-5The present invention provides a technical solution: a fiber cotton paddress, including the box 1, the inner top wall of the casing 1, in communication, the inner side wall of the casing 1, is transferred by the bearing to connect with a third rod body. 15. The outer wall welding of the third rod 15 is welded, and the outer side wall of the stirring roller 14 is uniformly welded with a second rod body 13, and the inner side wall of the casing 1 has a first housing 7, the first housing 7. The inner side wall is mounted, and the inner side wall of the first housing 7 is sequentially mounted with two heating rods 24, and the inner side wall of the casing 1 is connected to the lower part of the first housing 7, and the fourth housing 21 is connected. The outer wall of the housing 21 is welded with a second plate body 19, and the upper surface of the second plate body 19 is mounted, the air opening of the exhaust opening and the inner side wall of the fourth housing 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com