Guided inspection of a semiconductor wafer based on systematic defects

A semiconductor, defect technology, used in the field of guided inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

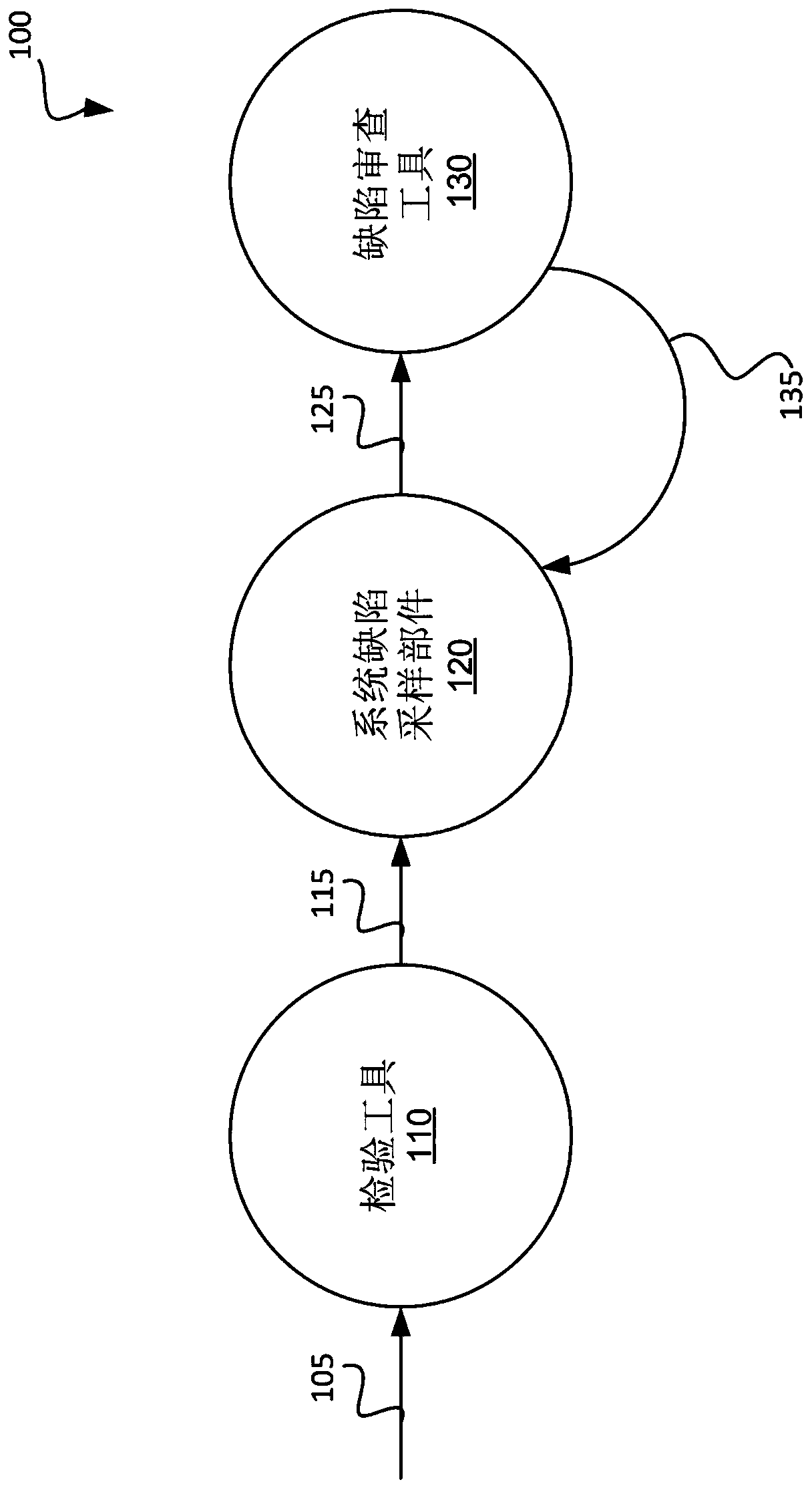

[0020] Aspects of the present disclosure relate to systematic defect-based guided inspection of semiconductor wafers. In general, semiconductor wafer inspection systems may be used to perform inspection of semiconductor wafers. For example, semiconductor wafer inspection systems may be used to identify defects at semiconductor wafers.

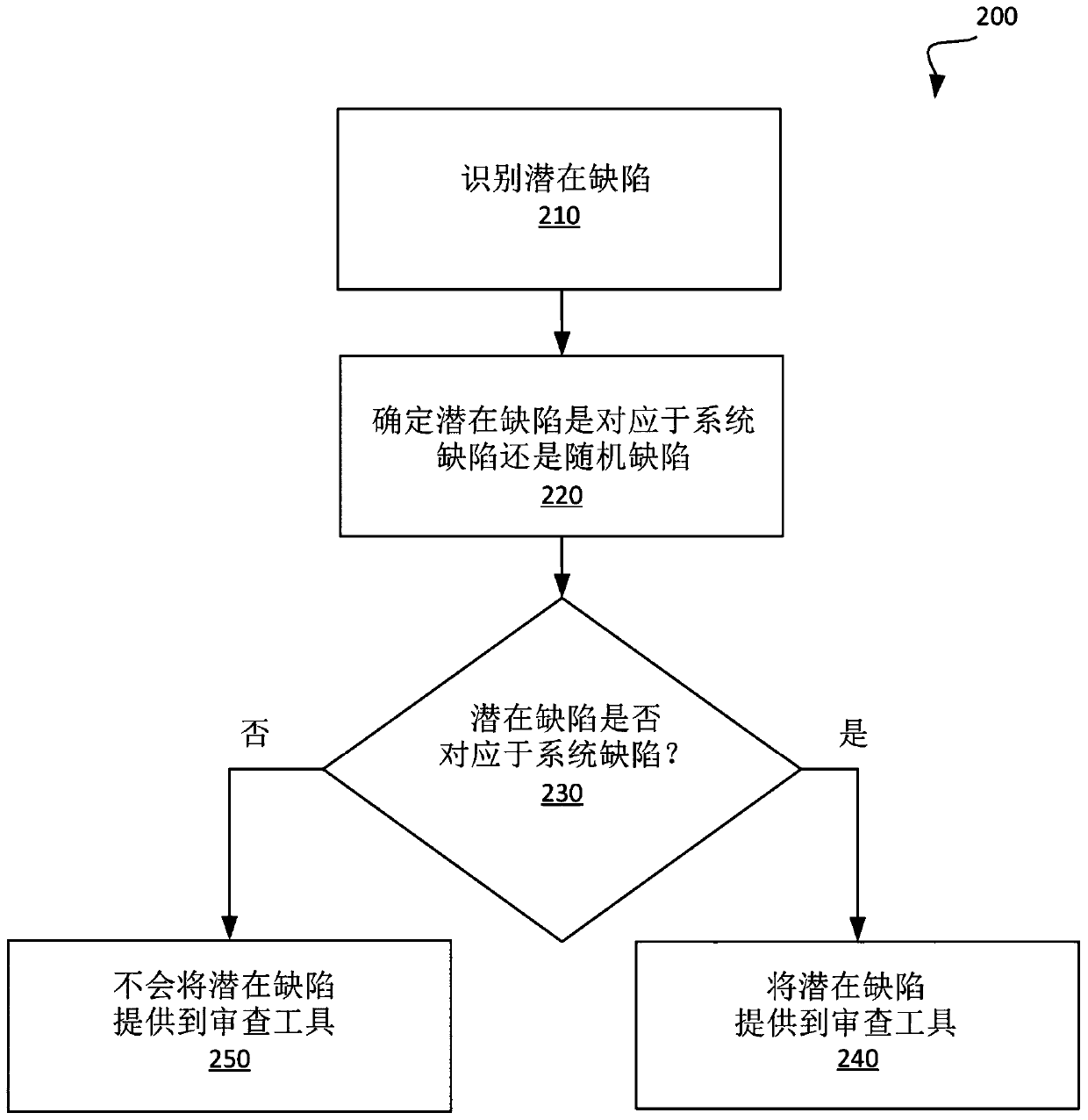

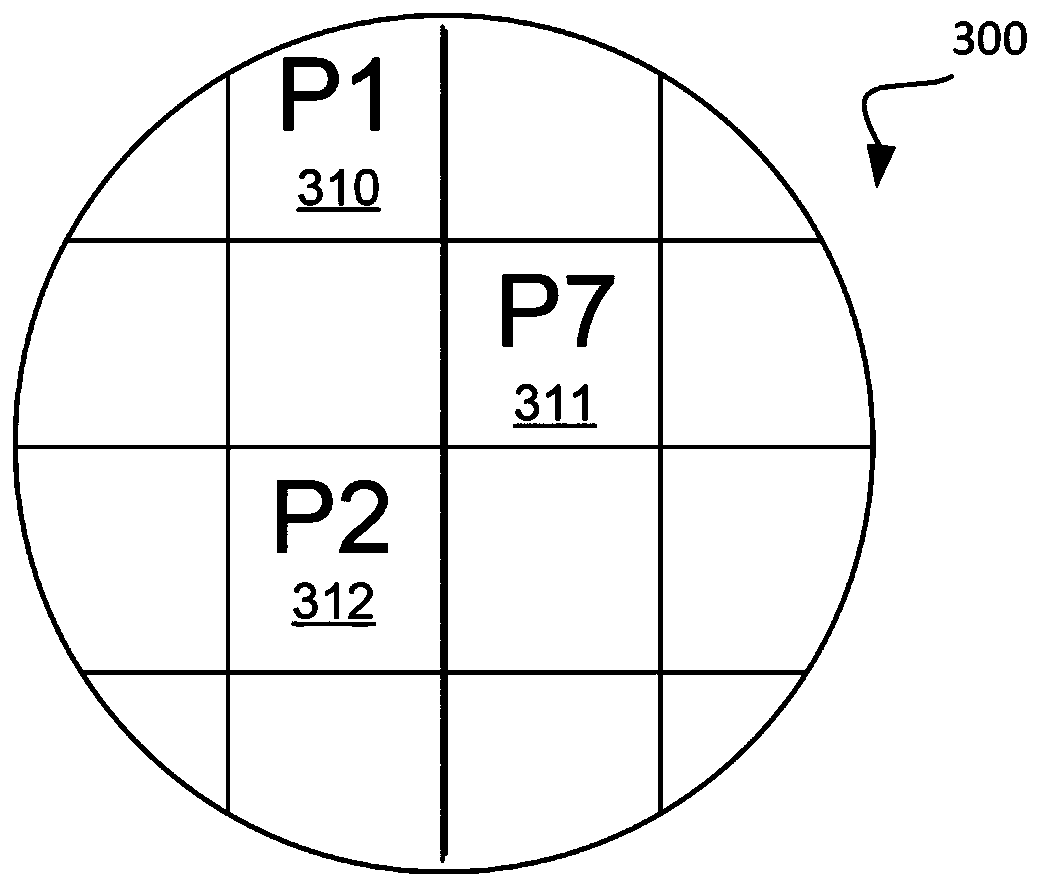

[0021] A semiconductor wafer inspection system may include optical tools and defect review tools. For example, optical tools may be used to identify potential or candidate defects at semiconductor wafers after or during the manufacturing process. Subsequently, a defect review tool may be used to examine, classify, or determine whether a candidate defect is an actual defect or not (eg, a "false alarm"). Where the design of the semiconductor wafer or other such technology (eg, fabrication process, material usage, or design features) is new, the fabrication process of the semiconductor wafer may be unstable and result in lower yields of semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com