Control device for internal combustion engine

A technology for internal combustion engines and control devices, applied in mechanical equipment, engine control, engine components, etc., can solve the problems that the condensate may be transported and damaged when the internal combustion engine is restarted, and reduce the risk of freezing the control device , reduce exhaust emissions, and avoid freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

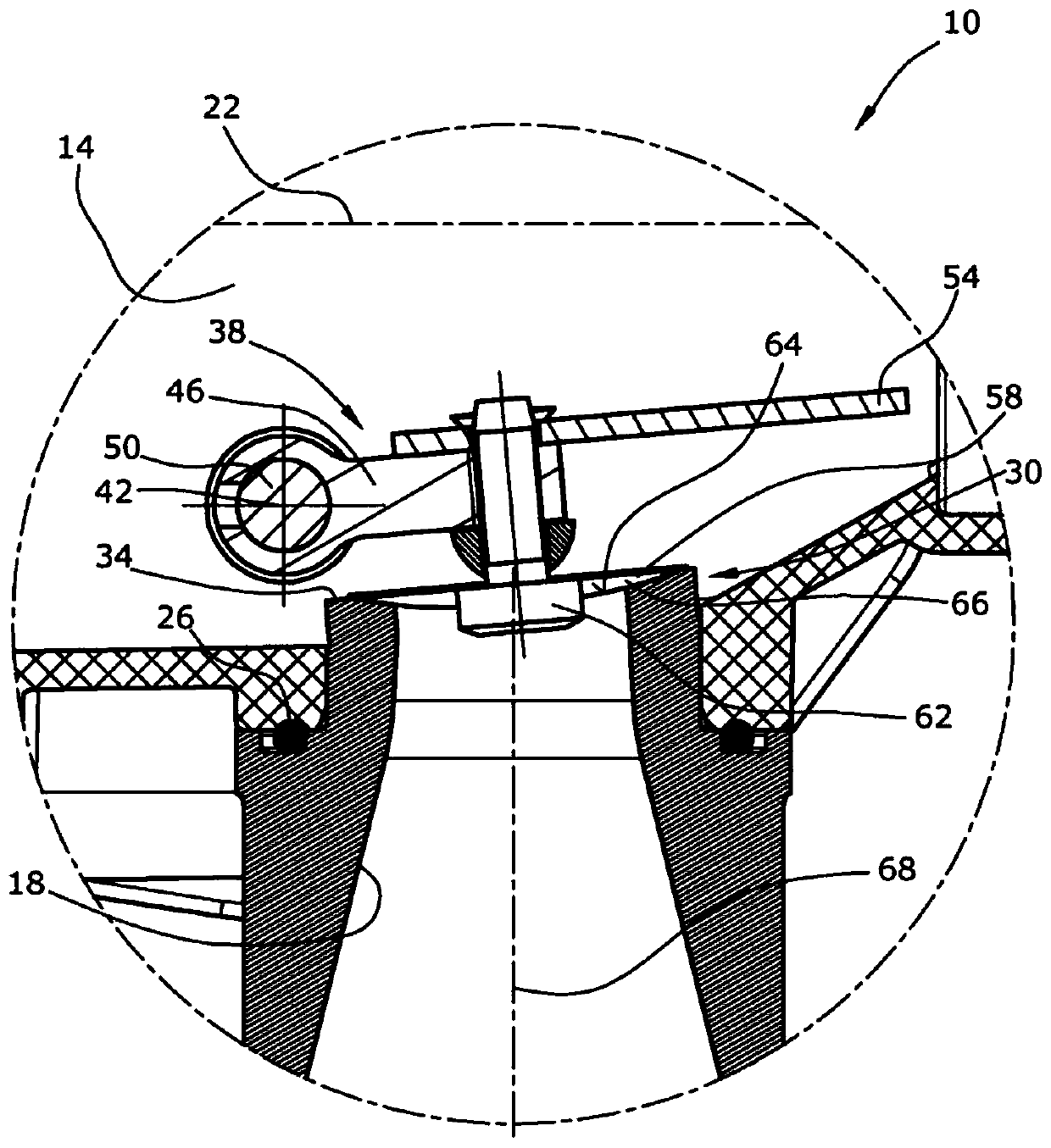

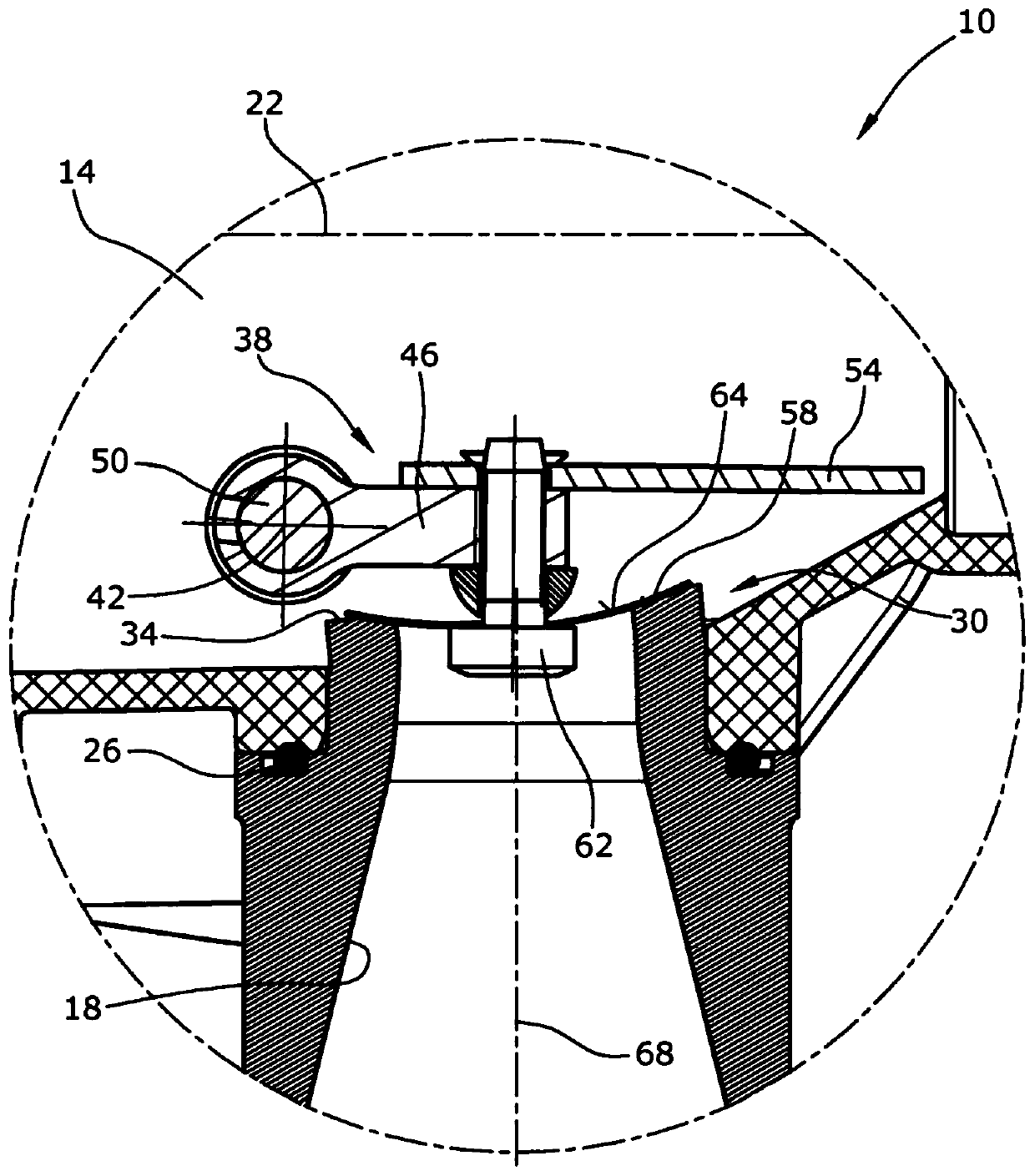

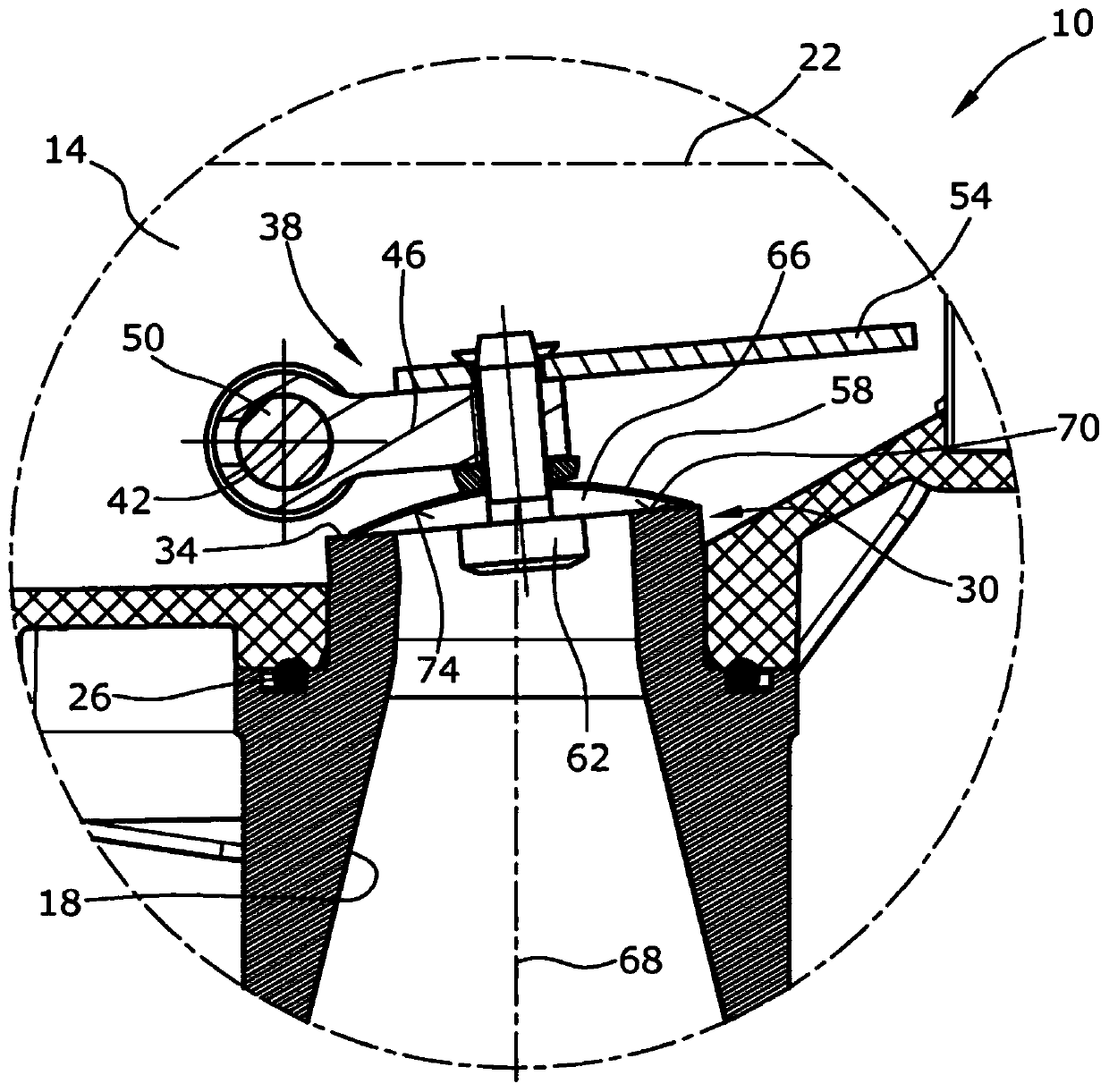

[0028] figure 1 A control device 10 for an internal combustion engine according to a first exemplary embodiment of the invention is shown. The regulating device 10 includes an intake passage 14, through which air is delivered to the internal combustion engine; and an exhaust gas recirculation passage 18, which is perpendicular to the central axis 22 of the intake passage and leads into the intake passage 14, and the exhaust gas can pass through the intake passage 14 for recirculation. The exhaust gas recirculation channel 18 is sealed relative to the intake channel 14 by a seal 26 .

[0029] A valve seat 34 is formed at the end opening 30 of the exhaust gas recirculation channel 18 . Arranged in the intake channel 14 is a control body 38 , via which control body the recirculated exhaust gas flow from the exhaust gas recirculation channel 18 can be controlled. The control body 38 is pivotable by means of an actuator (not shown) along a pivot axis 42 orthogonal to the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com