Thermochromic coating, preparation method thereof, heating device and cooking equipment

A technology for temperature-sensitive discoloration and heating appliances, which can be applied to coatings, devices for coating liquids on surfaces, special surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

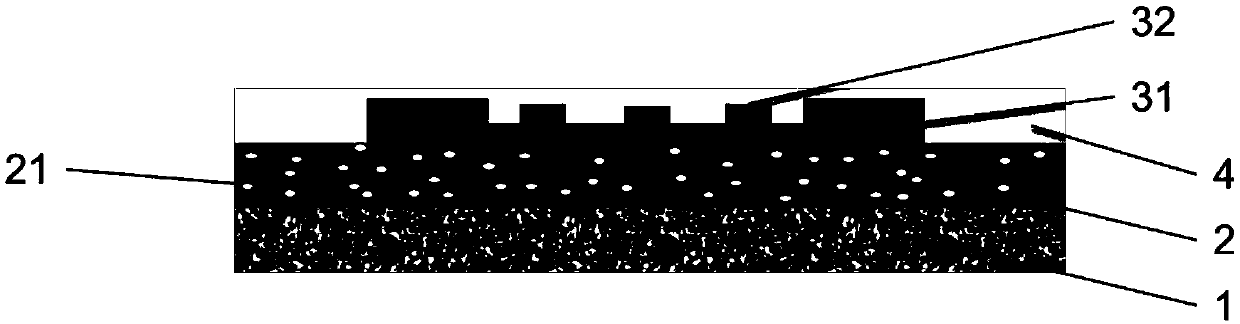

[0052] The second aspect of the present invention provides a method for preparing a thermochromic coating, wherein the method comprises the following steps:

[0053] (1) substrate 1 is pretreated;

[0054] (II) roughening the substrate obtained through step (I);

[0055] (III) coating paint on the surface of the substrate obtained through step (II) and carrying out the first surface drying treatment to form the primer layer 2;

[0056] (IV) Coating a thermochromic decorative layer 3 on the base coat 2 and carrying out a second surface-drying treatment; and

[0057] (V) Coating a top coat 4 on the thermochromic decorative layer 3 and performing sintering treatment.

[0058] According to the present invention, in step (1), the substrate 1 is pretreated, wherein the pretreatment method includes carrying out degreasing and derusting treatment on the substrate 1, the method for deoiling and derusting is not particularly limited, and can be respectively Various methods commonly u...

Embodiment 1

[0078] This embodiment is used to illustrate the thermochromic coating prepared by the method of the present invention, as well as heating appliances and cooking equipment.

[0079] (1) Pretreat the base of the aluminum pan (thickness 2.5mm), the pretreatment method includes: a) degreasing at 55°C for 8 minutes; b) cleaning with deionized water; c) drying at 100°C 5min;

[0080] (2) Roughening treatment: d) Use 60-80 mesh brown steel grit to sandblast the inner surface of the aluminum pot base under the pressure of 0.6MPa jet airflow to make the surface roughness Ra3μm, and then use airflow (air) Blow off the remaining powder particles on the inner surface of the base of the pot body; e) use 40% by weight of NaOH solution for alkaline washing at 80°C for 1 minute; f) neutralize with 20% by weight of nitric acid solution for 3 minutes; g) use deionized After washing with water, dry at 300°C for 12 minutes;

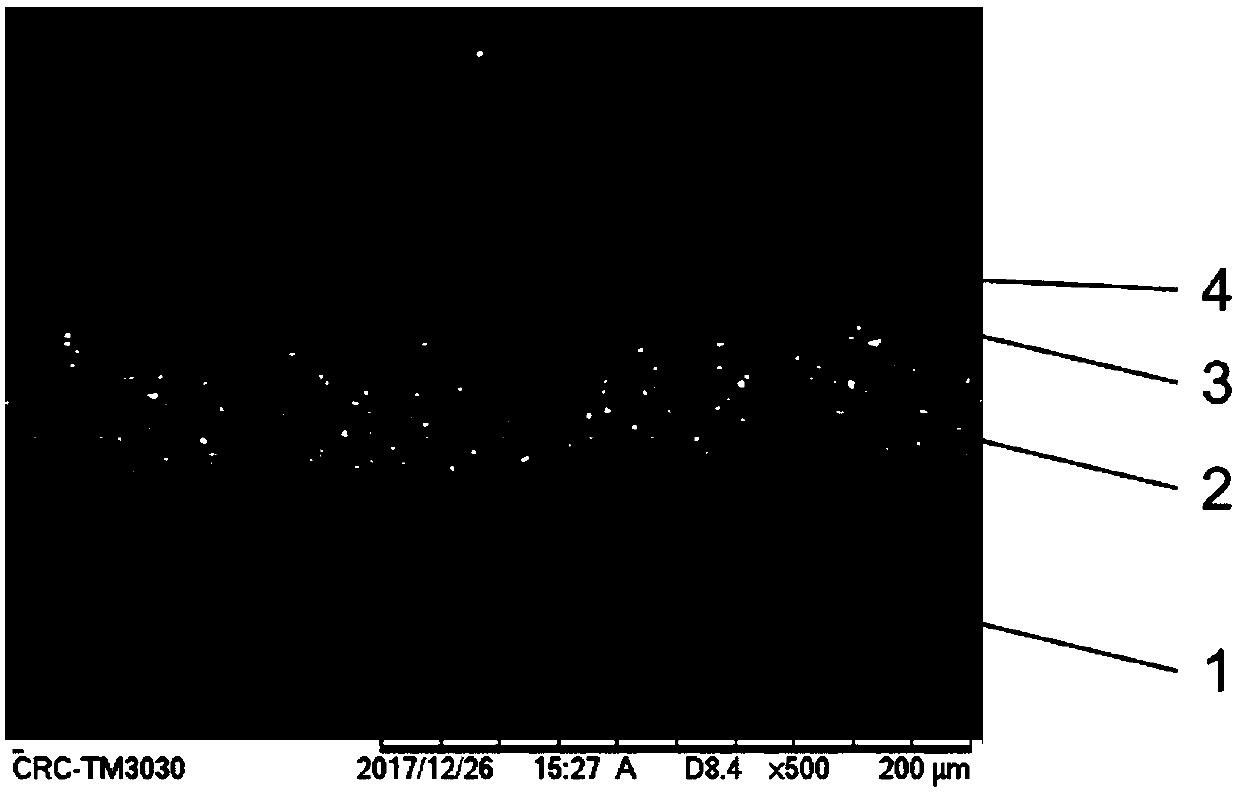

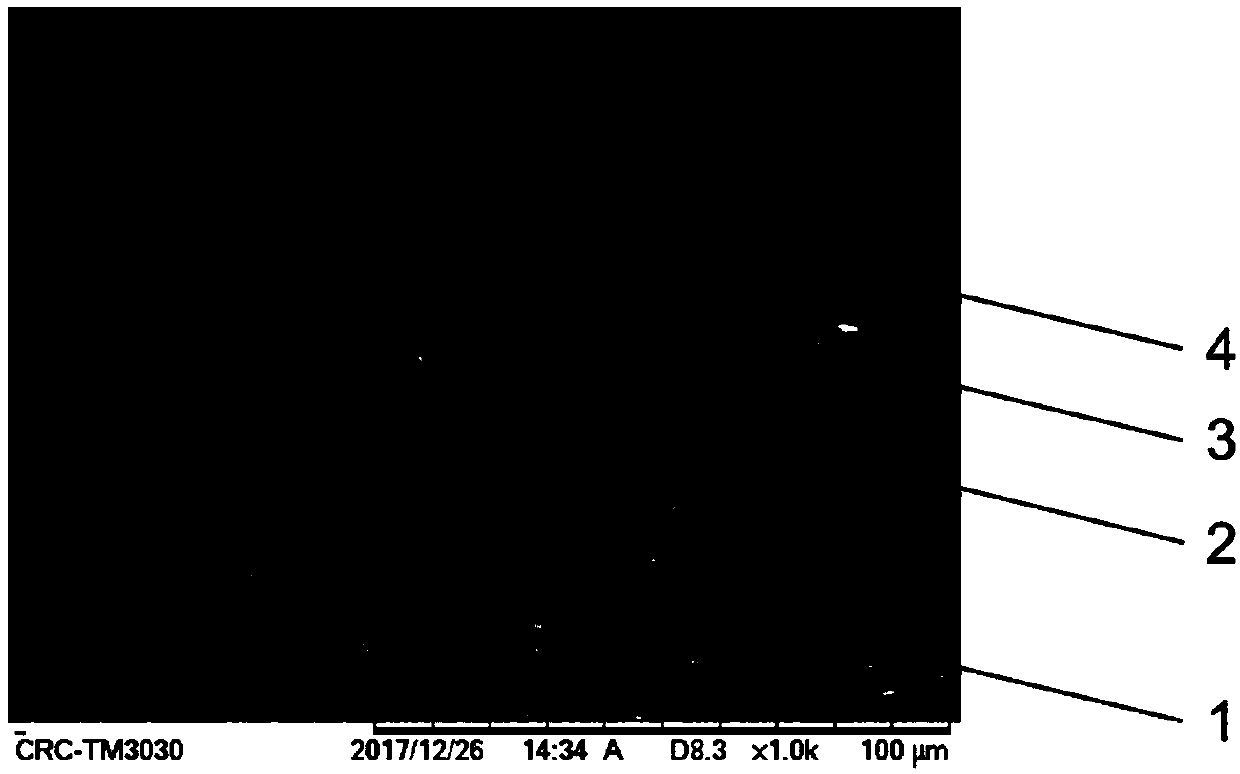

[0081]On the inner surface of the substrate 1, a color lining layer ...

Embodiment 2

[0089] This embodiment is used to illustrate the thermochromic coating prepared by the method of the present invention, as well as heating appliances and cooking equipment.

[0090] The thermochromic coating is prepared according to the method of Example 1, the difference being that: the coating is specifically as shown in Table 1; the roughness Ra of the substrate surface obtained through step (2) is 3 μm; and

[0091] On the inner surface of the base 1, a color lining layer 31 is applied to a local area, and a primer layer 2 is applied to other areas, and a discoloration layer 32 is applied to a local area of the upper surface of the color lining layer 31; and

[0092] In step (3), the conditions of the first surface drying treatment: the temperature is 150° C., and the time is 8 minutes;

[0093] In step (4), the conditions of the second surface drying treatment: the temperature is 100°C, and the time is 1min;

[0094] In step (5), the conditions of the sintering treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com