Pipeline descaler for oil production workers

A descaling device and pipeline technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as difficult cleaning, difficult cleaning, and inability to rotate pipelines, and achieve flexible use and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

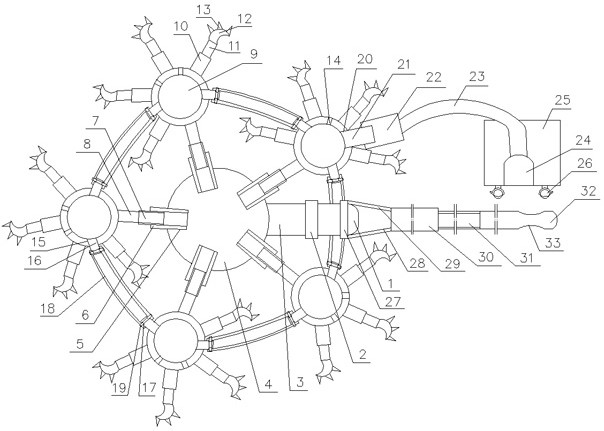

[0017] A pipeline descaler for oil production workers, comprising: a forward and reverse motor 1, the forward and reverse motor is connected to a shaft coupling 2, the shaft coupling is connected to a rotating shaft 3, and the rotating shaft is welded with a ball 4. The ball has a set of internally threaded holes 5, the internally threaded holes are connected to an externally threaded sleeve 6, and the externally threaded sleeve protrudes from the outside of the ball, and the externally threaded sleeve has internal thread, the external thread sleeve is connected to the adjusting screw 7, the adjusting screw is connected to the support rod 8, the support rod is welded with a hollow ball 9, and the outer surface of the hollow ball is welded with a set of fixed thread sleeves 10, The fixed threaded sleeve is connected with an externally threaded rod 11, the outer end of the externally threaded rod has a hook 12, and the outside of the hook has a cone point 13, and the hollow ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com