Preparation method of titanium alloy thin-wall lightweight covering cap part

A lightweight, titanium alloy technology, applied in the field of titanium alloy processing, to achieve good integrity, ensure strength and rigidity, and achieve the effect of lightweight and high strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

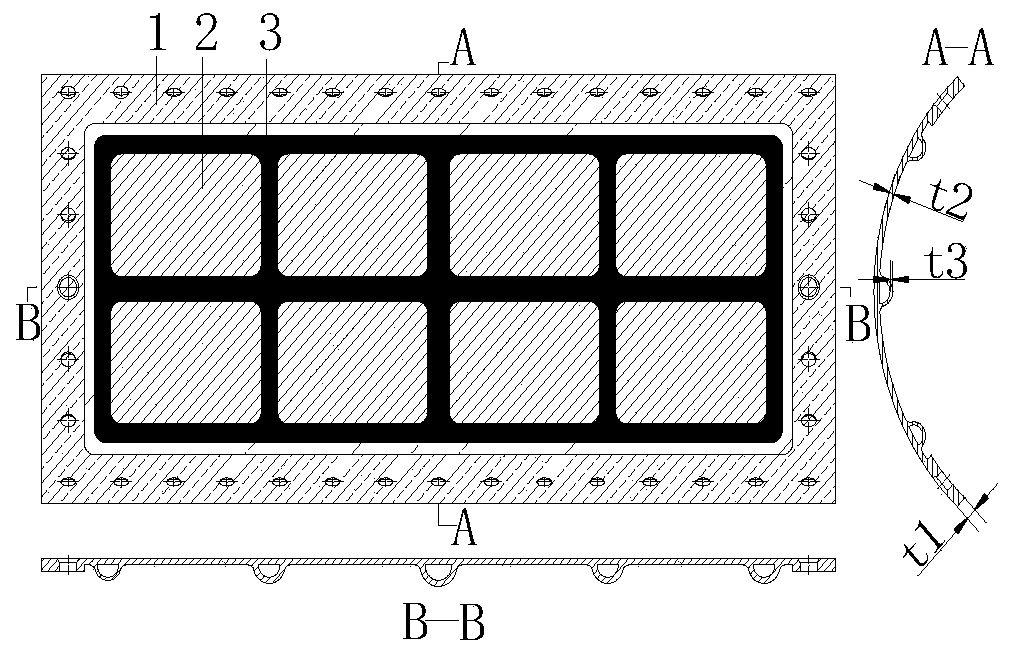

[0038] This example proposes a method for preparing a titanium alloy thin-walled lightweight flap. The shape of the prepared flap is as follows figure 1 As shown, it has a surrounding mounting surface 1 , a middle diffusion welding area 2 and a rib area 3 . Wherein, the thickness t1 of the surrounding mounting surface 1 is 4 mm, the thickness t2 of the middle diffusion welding area 2 is 2 mm, and the thickness t3 of the rib area 3 is 0.5 mm.

[0039] The preparation method of the titanium alloy thin-walled lightweight cover specifically includes the following steps:

[0040] S1. Mold design

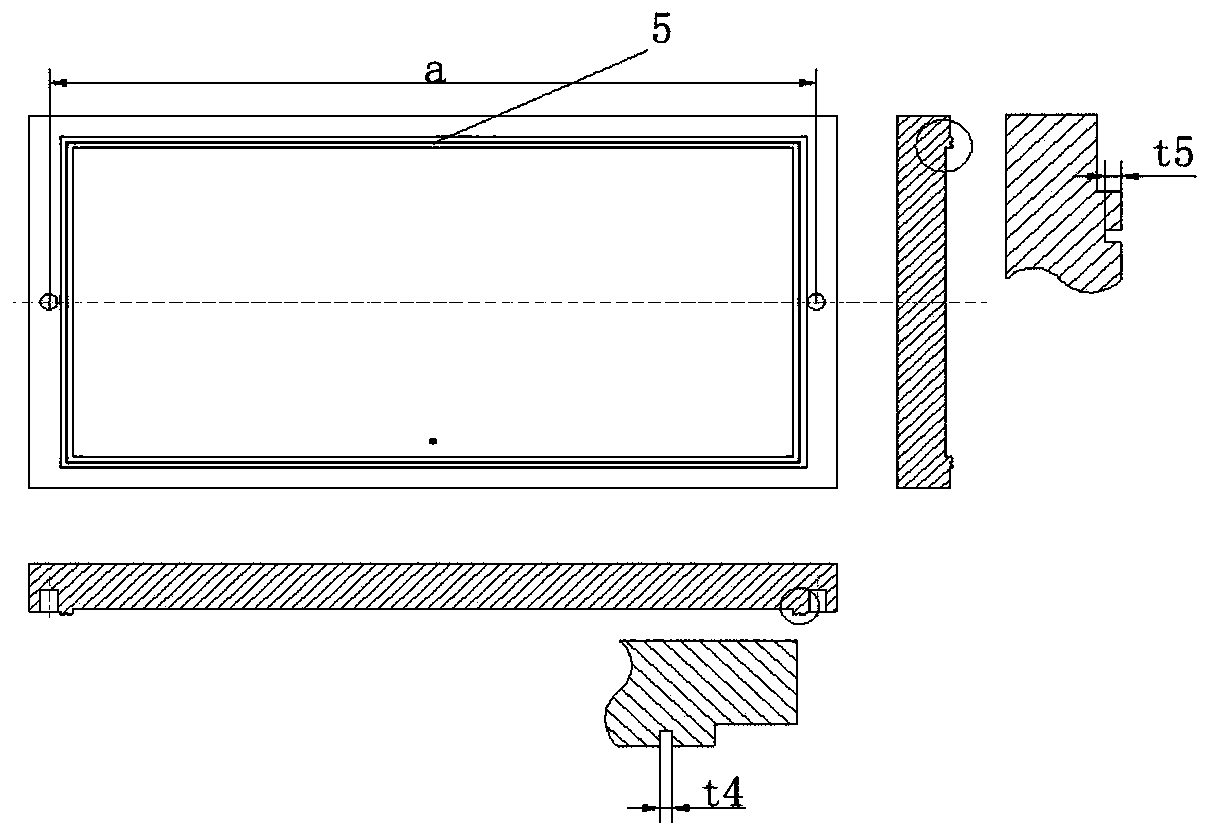

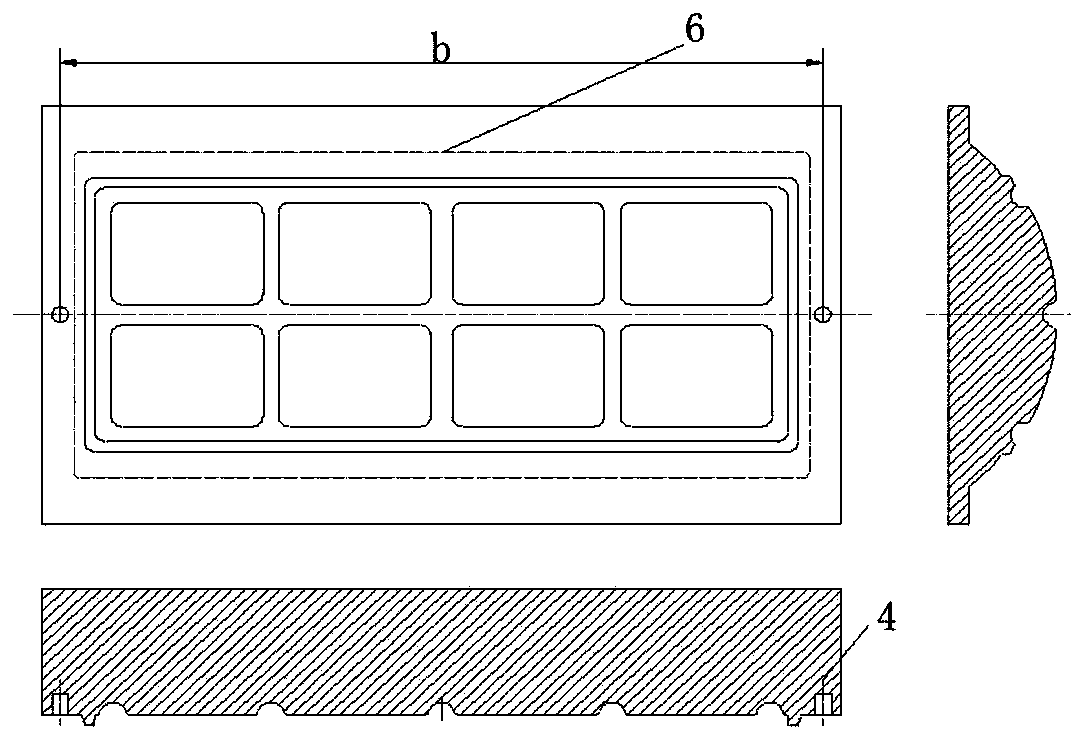

[0041] According to the final theoretical shape of the part, the flat diffusion welding mold and the hot pressing superplastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com