Chemical oxygen generator drug block forming device

An oxygen generator and molding device technology, which is applied to material molding presses, presses, manufacturing tools, etc., can solve the problem that the grain cannot meet the requirements, achieve convenient and quick demoulding, improve the pressing efficiency, and avoid being easily broken. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific examples.

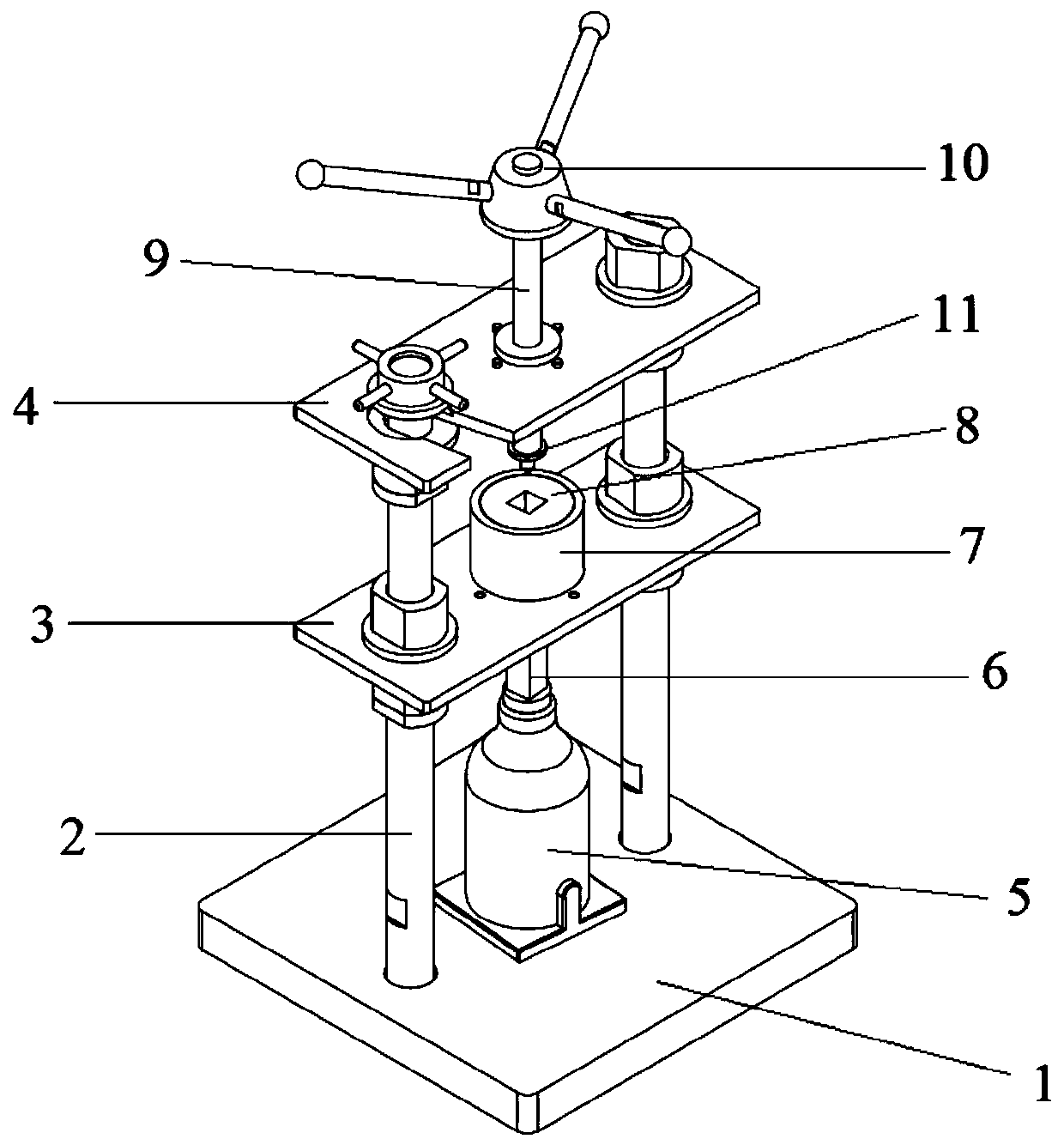

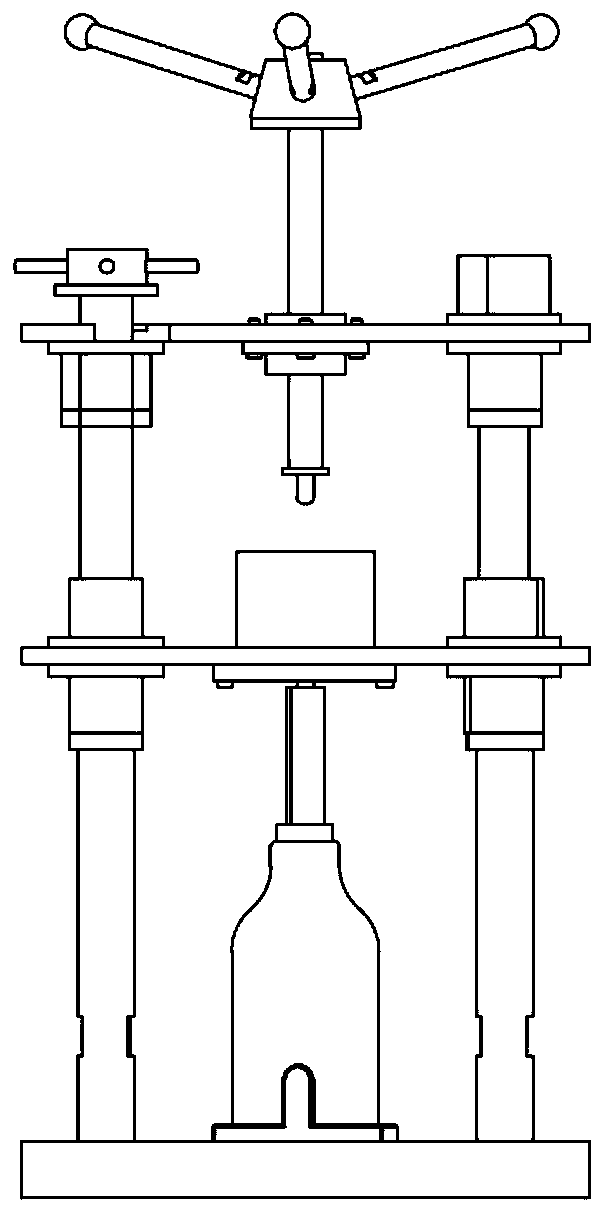

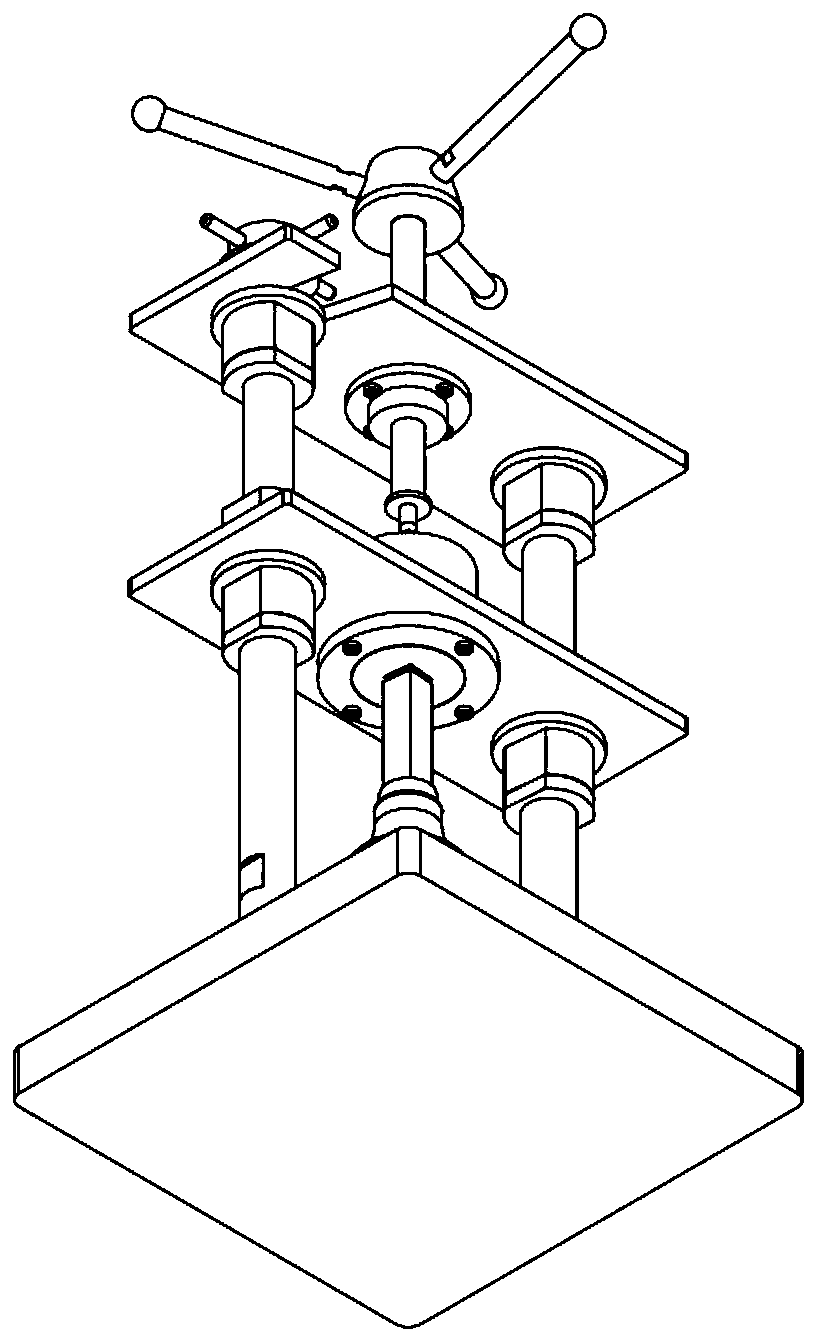

[0021] Such as Figure 1-4 As shown, a chemical oxygen generator drug block forming device, the device includes a base 1, a fixed pillar 2, a mold fixing plate 3, a beam plate 4, a pressure device 5, a core 6, a mold sleeve 8, and a hollow mold 7. Liftable compression lead screw 9, hand wheel 10 and pressure block 11, wherein, fixed pillars 2 are provided on both sides of the base 1, and the mold fixing plate 3 is located directly above the base 1 and fixed in the middle of the fixed pillar 2 , the crossbeam plate 4 is located directly above the mold fixing plate 3 and is fixed on the top of the fixing pillar 2; the center of the mold fixing plate 3 has a through hole, and a mold sleeve 7 is installed at the through hole, and the mold sleeve 7 is provided with The hollow mold 8, the bottom of the mold sleeve 7 has a through hole matching the hollow mold 8; the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com