Variable-diameter coiling machine

A technology of coiling machine and reel, which is applied in the direction of coiling strips, thin material processing, transportation and packaging, etc. It can solve the problems of limited reel size, inability to realize diameter change, inability to realize ultra-thin stainless steel high-precision coiling, etc. , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

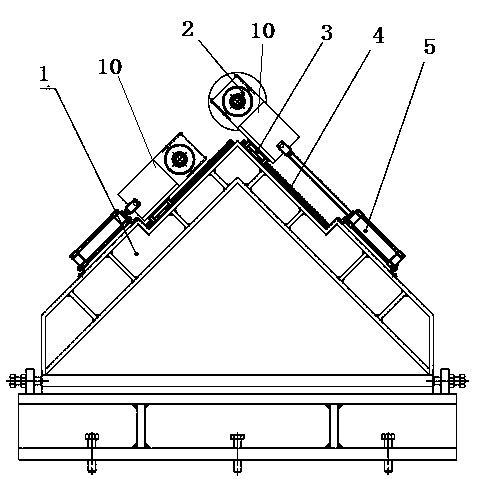

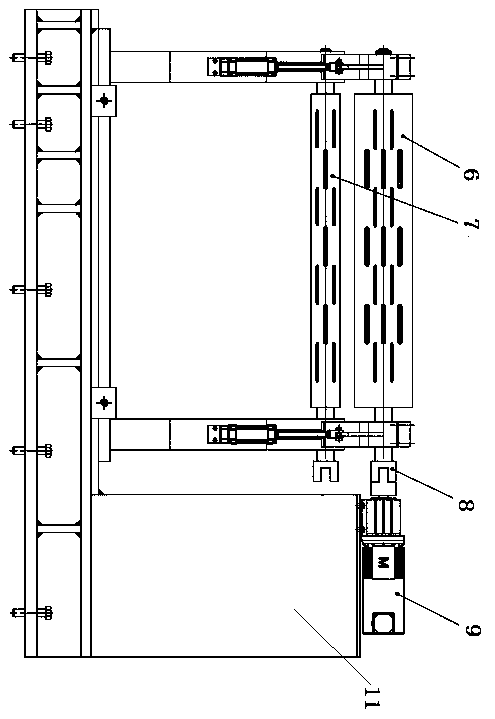

[0021] figure 1 , figure 2 As shown, a variable-diameter coiler includes a frame 1, and the two ends of a 6-inch reel 6 are fixed on one side of the frame 1 through a bearing seat 10. Holes and fixing bolts are arranged on the frame 1 to ensure that the reel is working. stability in the state. 6 inch reels 6 right-hand ends extend out bearing block 10 and are connected with motor 9 by shaft coupling 8, and the bearing blocks at 6 inch reels 6 two ends are respectively connected to a cylinder 5 by hinged ear hinge.

[0022] 3 inch reel two ends are fixed on the other side of frame 1 by bearing seat 10, and 3 inch reel 7 two ends bearing seats respectively connect a cylinder 5 by hinged ear, when changing reel, cylinder promotes spare reel to enter working position.

[0023] The bearing seat is connected with the linear slider, and the linear slider is set on the linear guide rail and slides on the linear guide rail;

[0024] The linear guide rail is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com