Steel structure hoisting and conveying equipment for steel structure factory building

A technology for conveying equipment and steel structures, which is used in transportation and packaging, load hoisting elements, load pulleys, etc. It can solve the problems of adding steel, falling, deformation and scratching of steel, and achieve the effect of improving stability and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

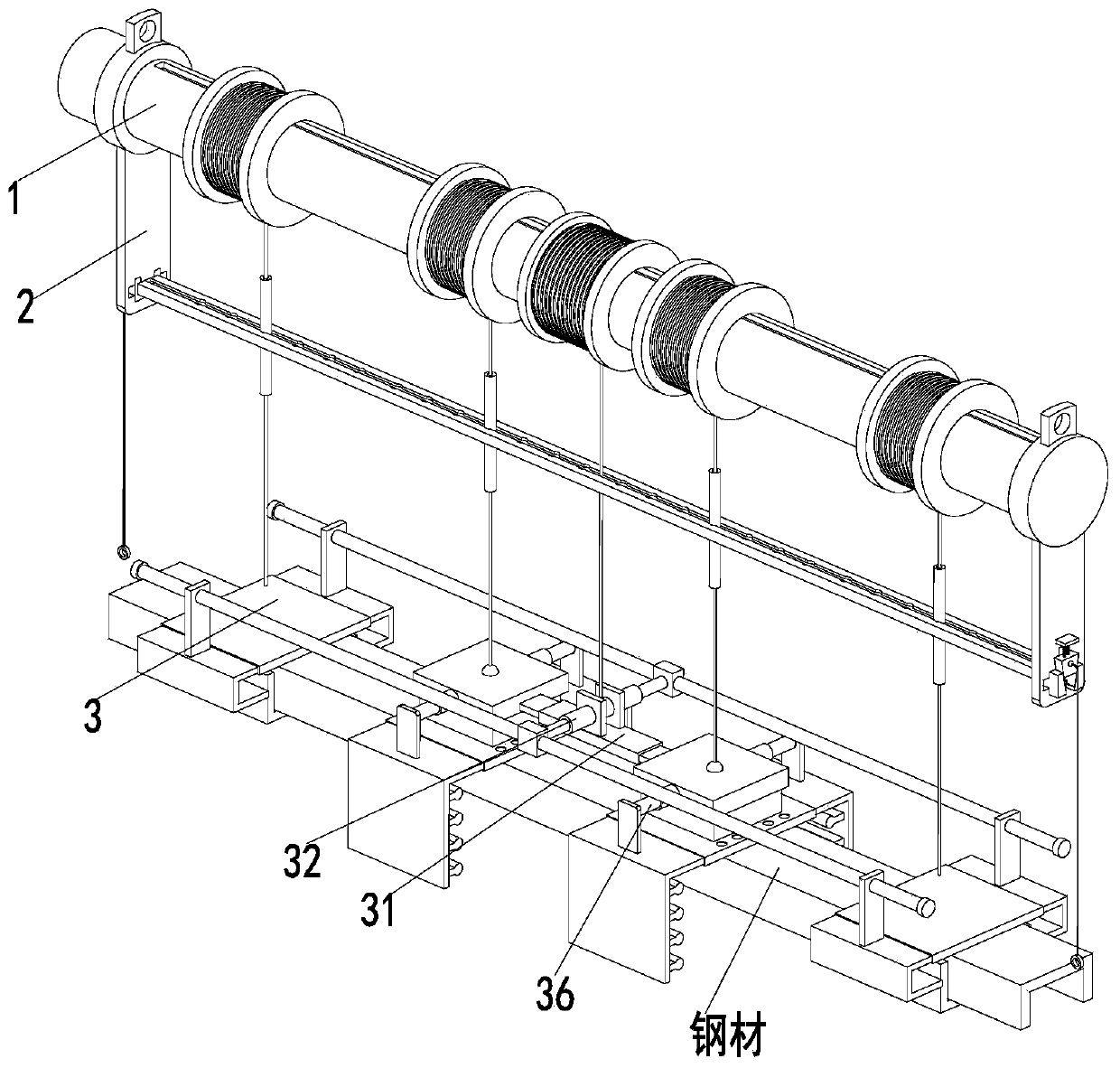

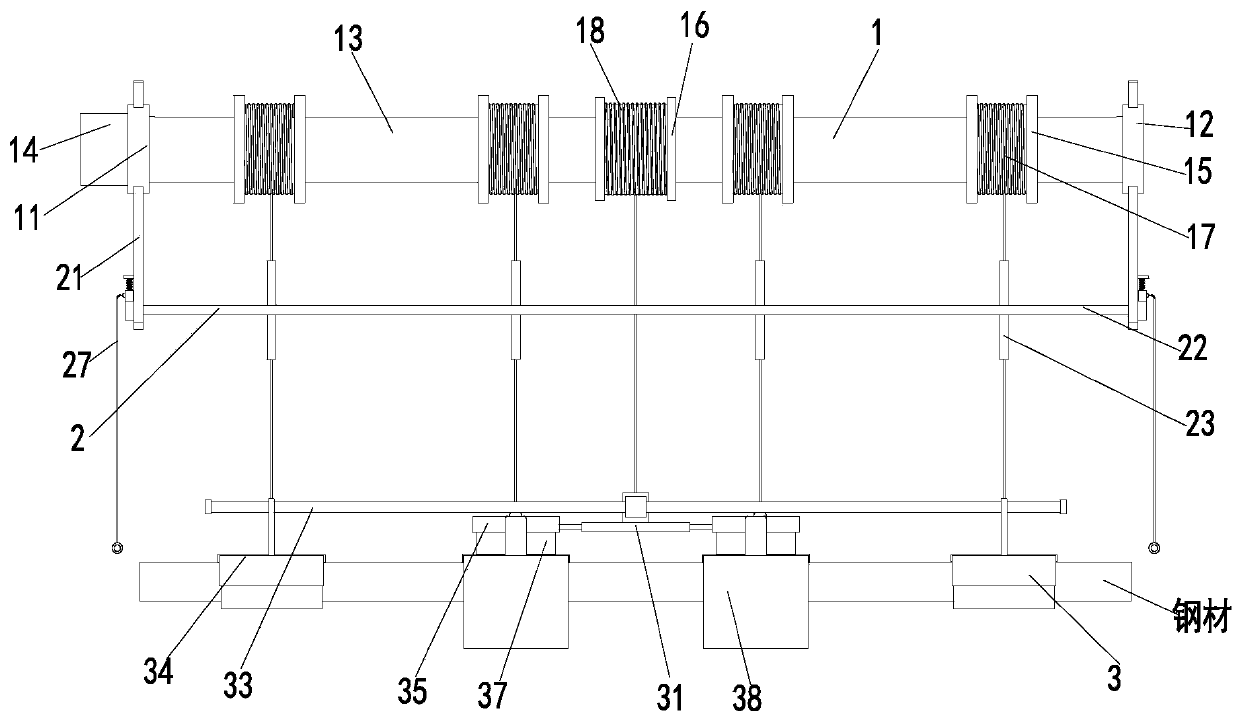

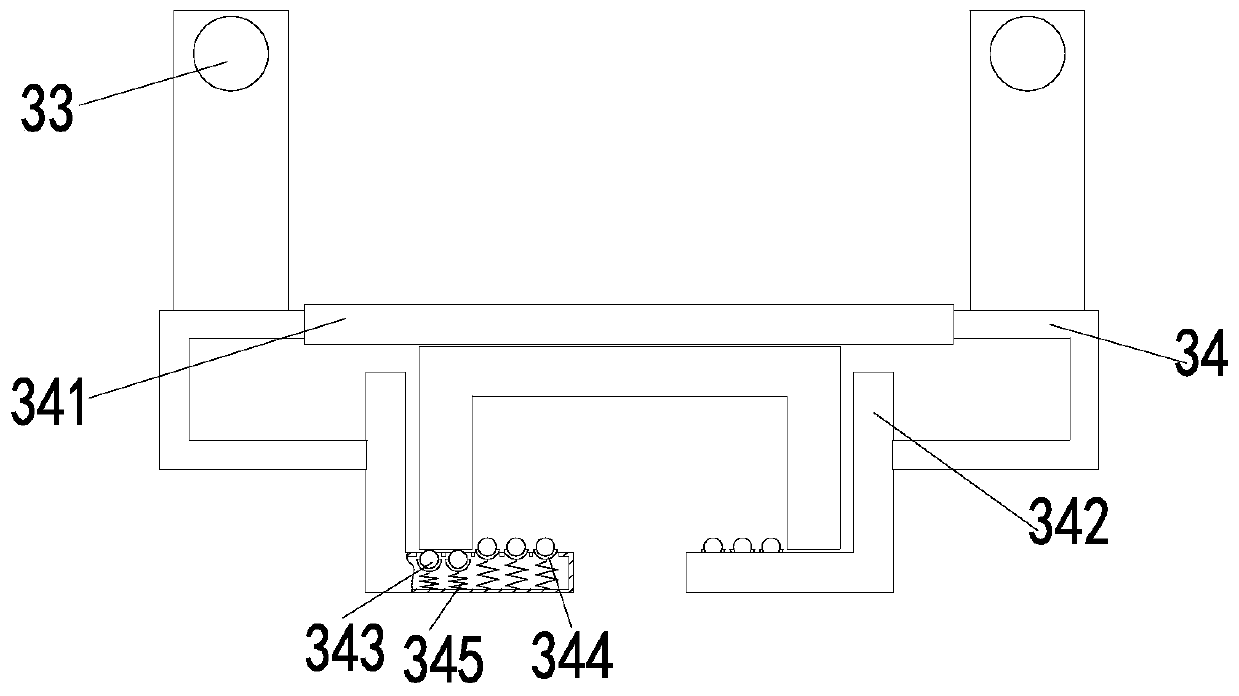

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0031] A steel structure hoisting and conveying equipment for building steel structures, including a retractable mechanism 1, an auxiliary mechanism 2 and a lifting mechanism 3, the lower end of the retractable mechanism 1 is arranged in sequence from top to bottom with an auxiliary mechanism 2 and a lifting mechanism 3, Both the auxiliary mechanism 2 and the hoisting mechanism 3 are connected to the side wall of the retracting mechanism 1; wherein:

[0032]The retractable mechanism 1 includes a No. 1 mounting plate 11, a No. 2 mounting plate 12, a retractable roller 13, a retractable motor 14, a lifting wire drum 15, a pulling wire drum 16, a lifting wire 17 and a pulling wire 18. The No. 1 mounting plate 11 and the No. 2 mounting plate 12 are sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com