Up-conversion light-emitting nano-crystal material, preparation method and applications thereof

A nanocrystalline and fluorescent technology, applied in nanotechnology, nanotechnology, nano-optics, etc., can solve the problems of probe material temperature calibration curve and temperature measurement performance change, temperature measurement error, etc., to shorten the ion distance and improve the energy level The effect of relevance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

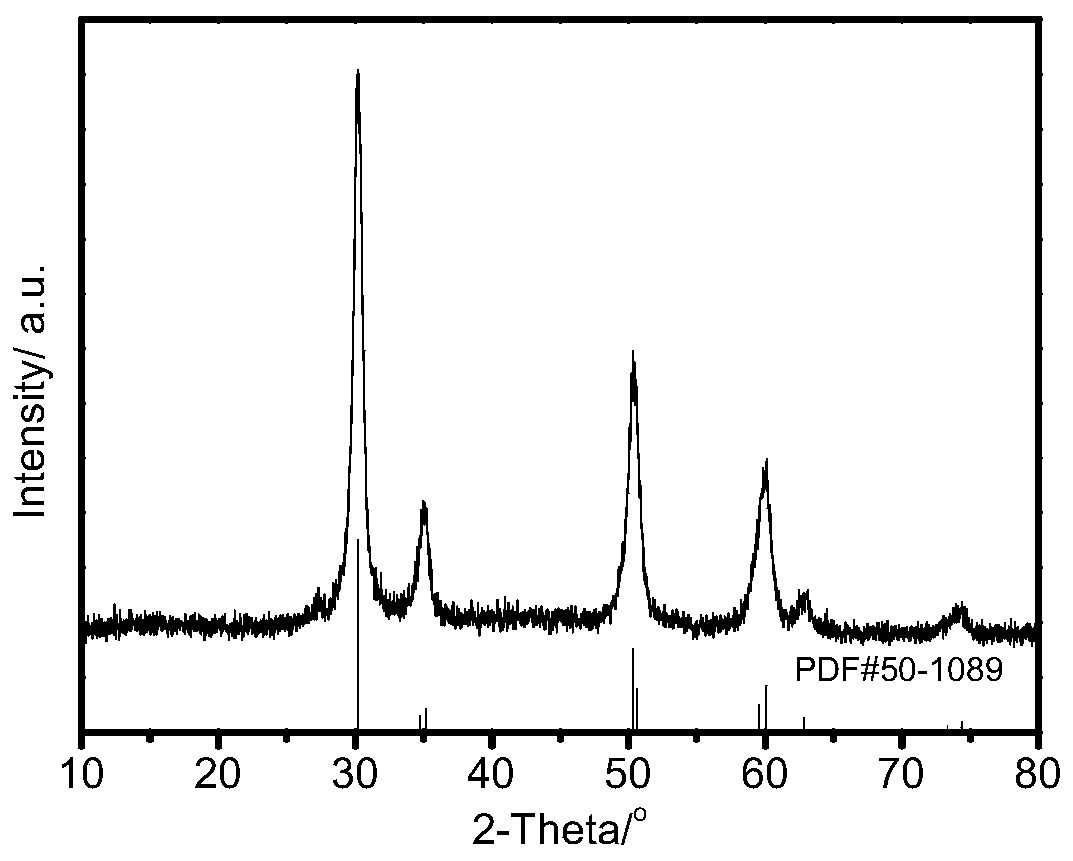

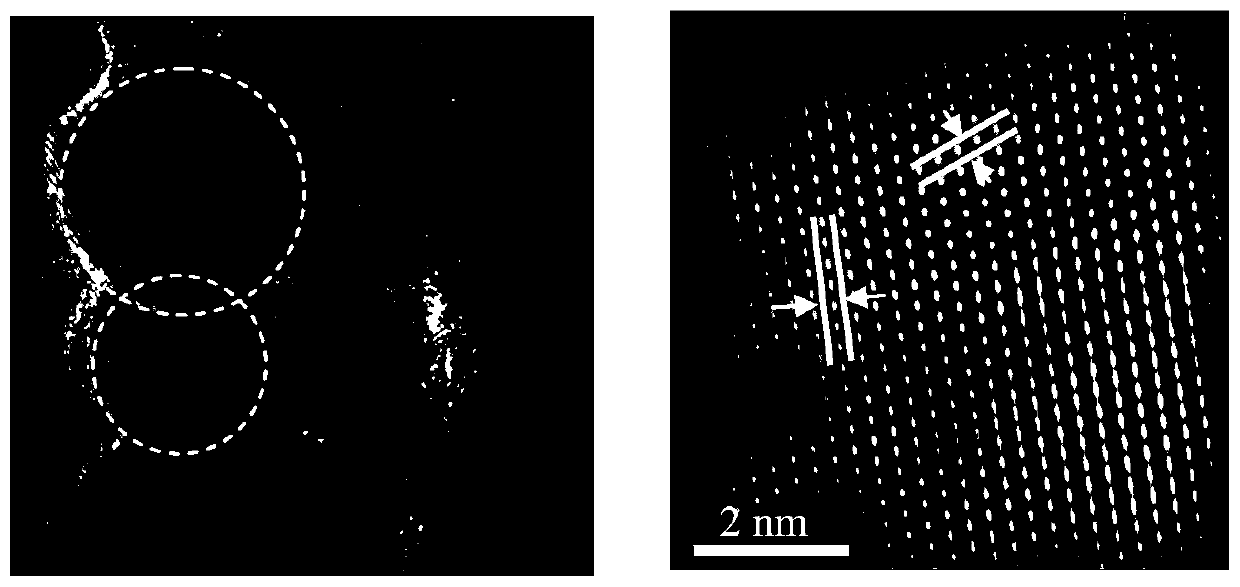

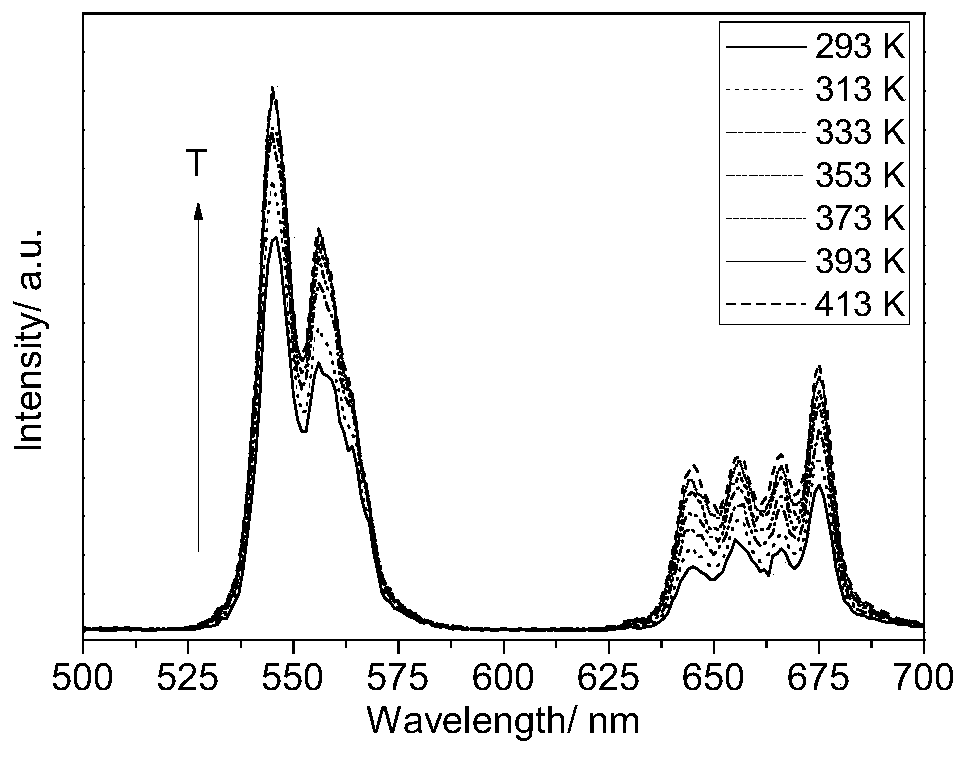

[0026] Weigh Zr(NO 3 ) 4 aqueous solution and Nb(NO 3 ) 5 Aqueous solutions of 92.5 and 2ml each were placed in a beaker and stirred for 10 minutes, then 19.2g of citric acid was added and stirred at 40°C on a magnetic stirrer to completely dissolve the citric acid; then 0.5mol / L of Ho(NO 3 ) 3 Aqueous solution and Yb(NO 3 ) 3 The aqueous solutions were 0.5 and 5ml respectively, and then ammonia water was added to adjust the pH value to 6, and a transparent solution was formed after stirring evenly. Afterwards, the mixed solution was placed in a constant temperature oven and kept at 90° C. for 8 hours to obtain a transparent wet gel, and then heated to 120° C. for 8 hours to form a dry gel. The obtained gel was put into a corundum crucible, placed in a well-type furnace, and heated from room temperature to 300 °C at a rate of 5 °C / min, and kept for 2 h. After the self-propagating combustion reaction, the gel transformed into a white precursor. Grind the white precursor ...

Embodiment 2

[0037] Weigh Zr(NO 3 ) 4 and Nb(NO 3 ) 5 Each solution was 76.8 and 10ml, placed in a beaker and stirred for 10min, then added 38.4g of citric acid; stirred at 50°C on a magnetic stirrer to completely dissolve the citric acid; then added dropwise 0.5mol / L of Ho(NO 3 ) 3 and Yb(NO 3 ) 3 The solutions were 1.2 and 12ml respectively, and then ammonia water was added to adjust the pH value to 7, and a transparent solution was formed after stirring evenly. Afterwards, the mixed solution was placed in a constant temperature oven and kept at 80°C for 12 hours to obtain a transparent wet gel, and then heated to 140°C for 9 hours to form a dry gel. The obtained gel was put into a corundum crucible, placed in a well-type furnace, and heated from room temperature to 400 °C at a rate of 8 °C / min, and kept for 2 h. The gel transformed into a white precursor after completing the self-propagating combustion reaction. Grind the white precursor evenly and put it into a tube furnace. Und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com