Straight slot flat tail screw assembly

A technology of screw assembly and flat tail, applied in the direction of screws, threaded fasteners, nuts, etc., can solve problems such as screw heads cannot be replaced, waste, and bolts are scrapped, and achieve good anti-loosening effect, easy to use, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

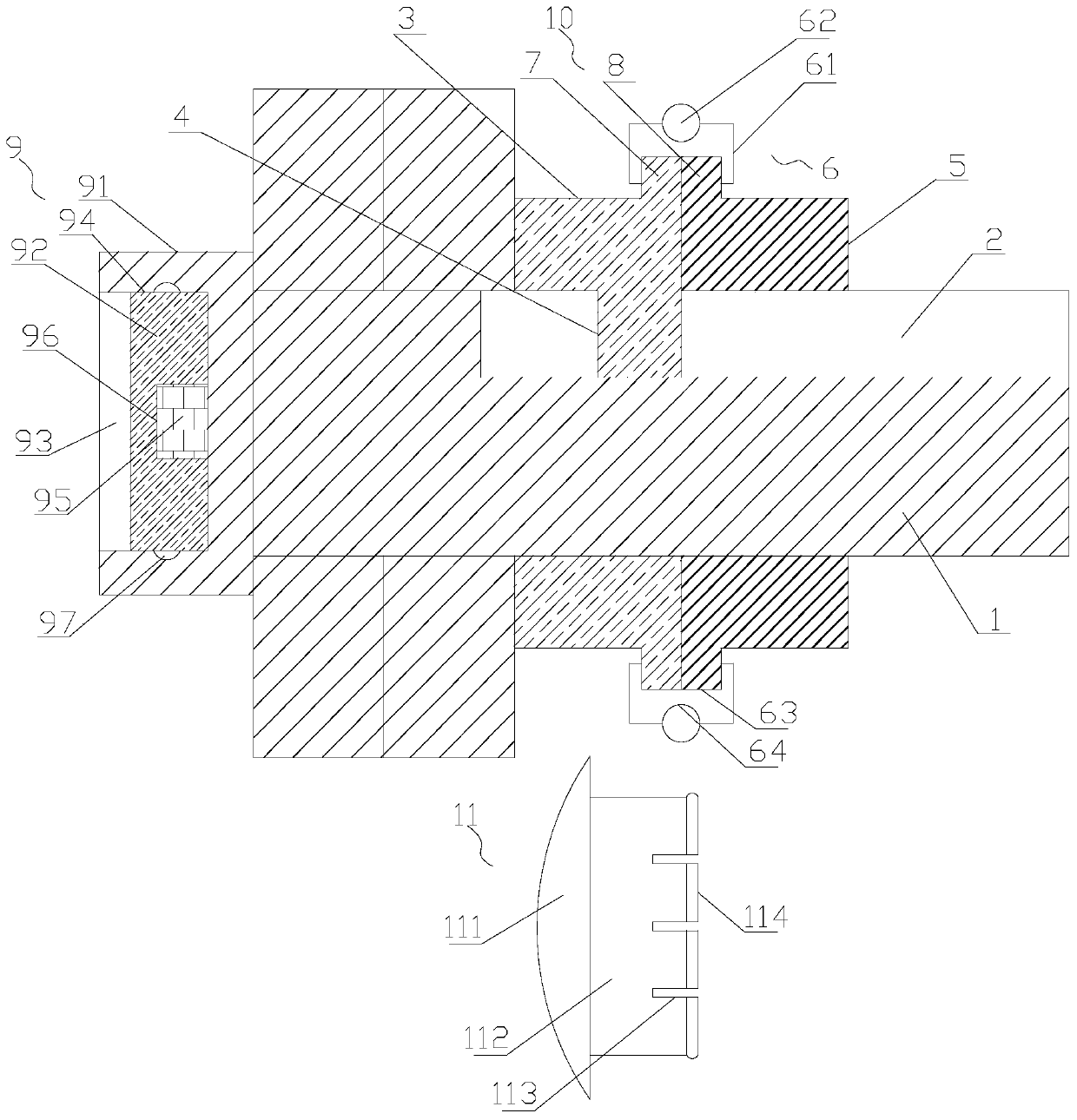

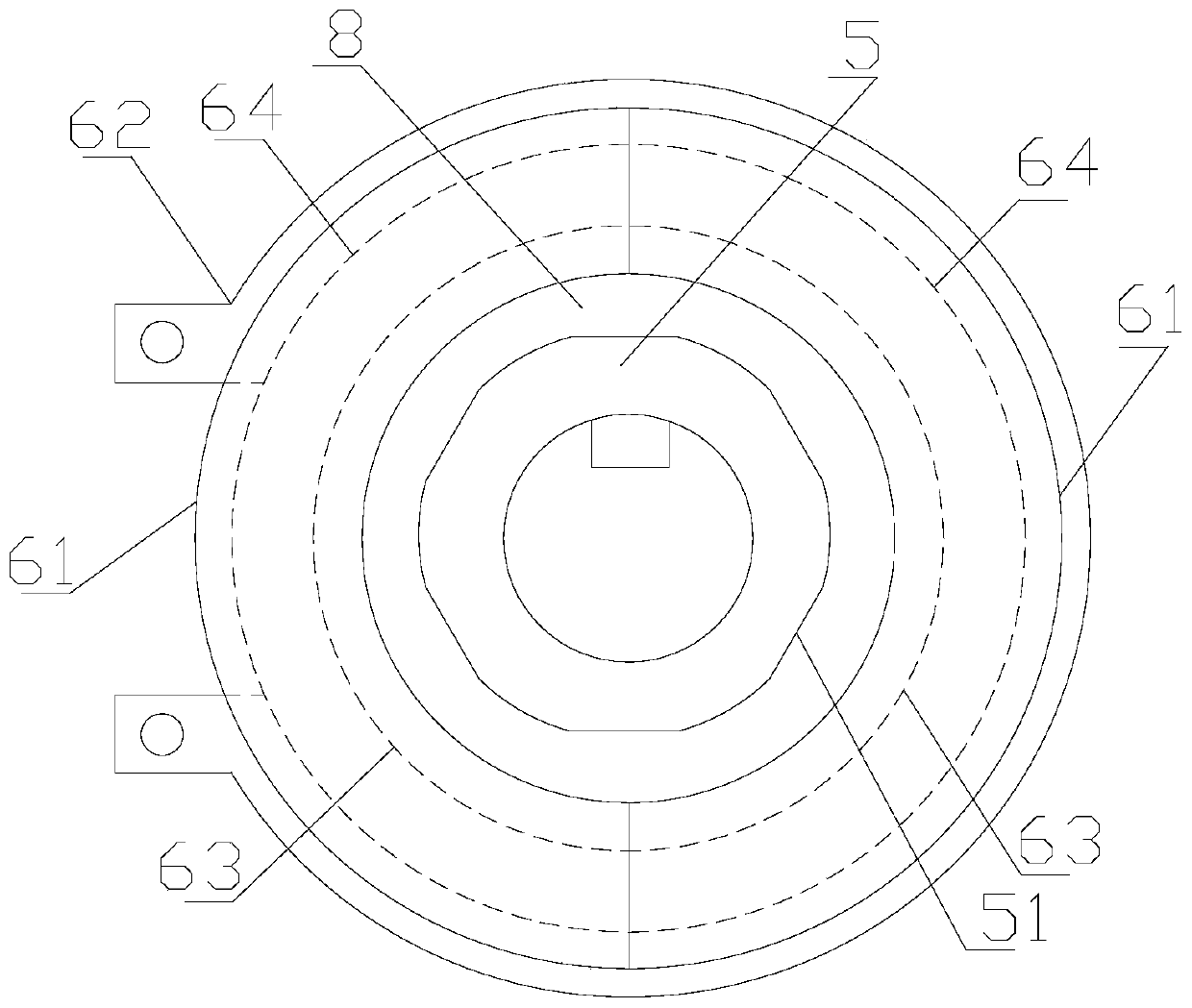

[0017] refer to figure 1 , 2 , a slotted flat tail screw assembly of the present invention, comprising a screw body 1, a chute 2, a pad 3, a positioning body 4, a nut 5, a fixing assembly 6 and a screw head assembly 9, the front end of the screw body 1 is provided with There is a screw head assembly 9, which includes a body 91 integrally formed on the front end of the screw body 1 and a twisting head 92 detachably connected to the body 91, the screw body 1 is provided with an open rear end The chute 2, the screw body 1 is covered with a pad 3, the inner ring surface of the pad 3 is provided with a positioning body 4 matching with the chute 2, and the rear end peripheral surface of the pad 3 is provided There is an annular connecting body I7, the screw body 1 is provided with a nut 5 positioned at the back of the pad 3, the front end peripheral surface of the nut 5 is provided with an annular connecting body II8, and the annular connecting body I7 and the annular The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com