Real-time calibration method for array type MEMS magnetic sensor

A technology of magnetic sensor and calibration method, applied in the field of MEMS magnetic sensor, capable of solving problems such as bias error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0135] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0136] A specific application scenario of the present invention is introduced below:

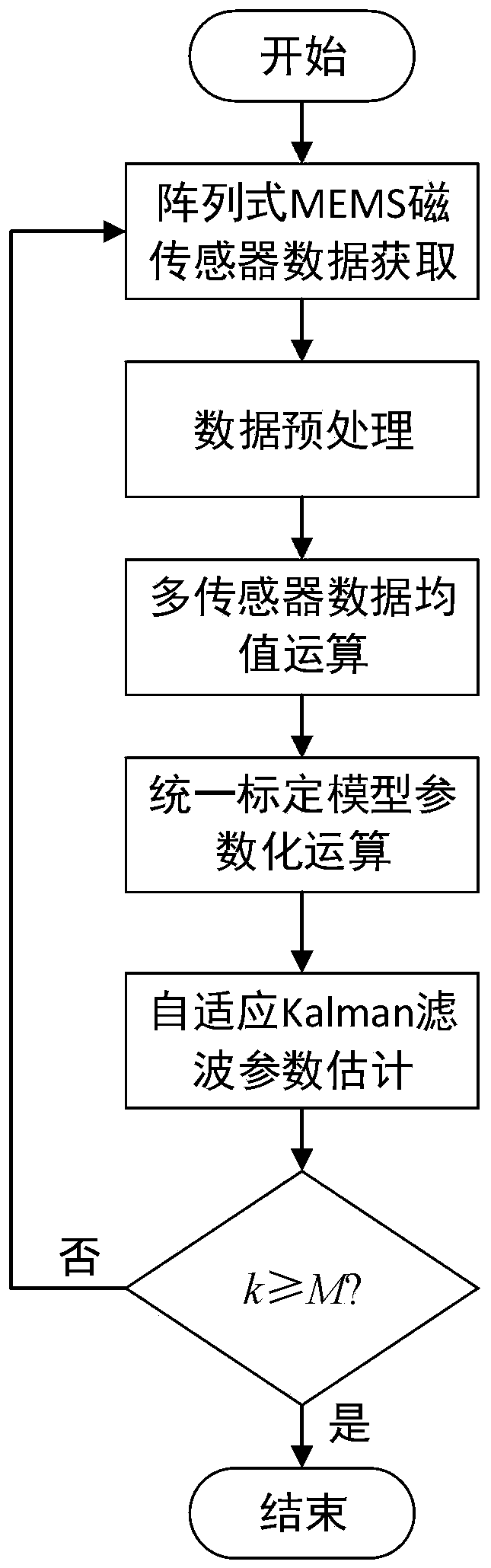

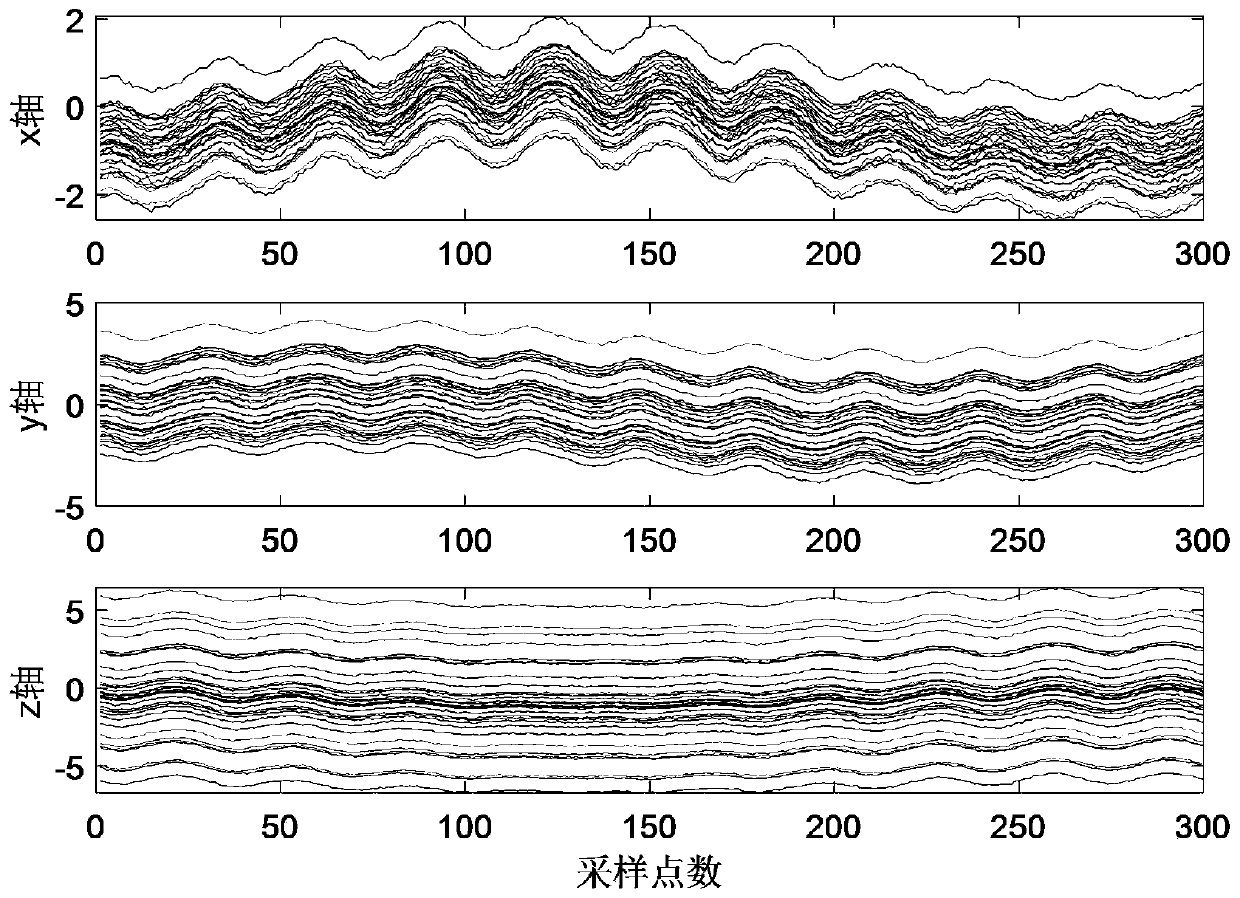

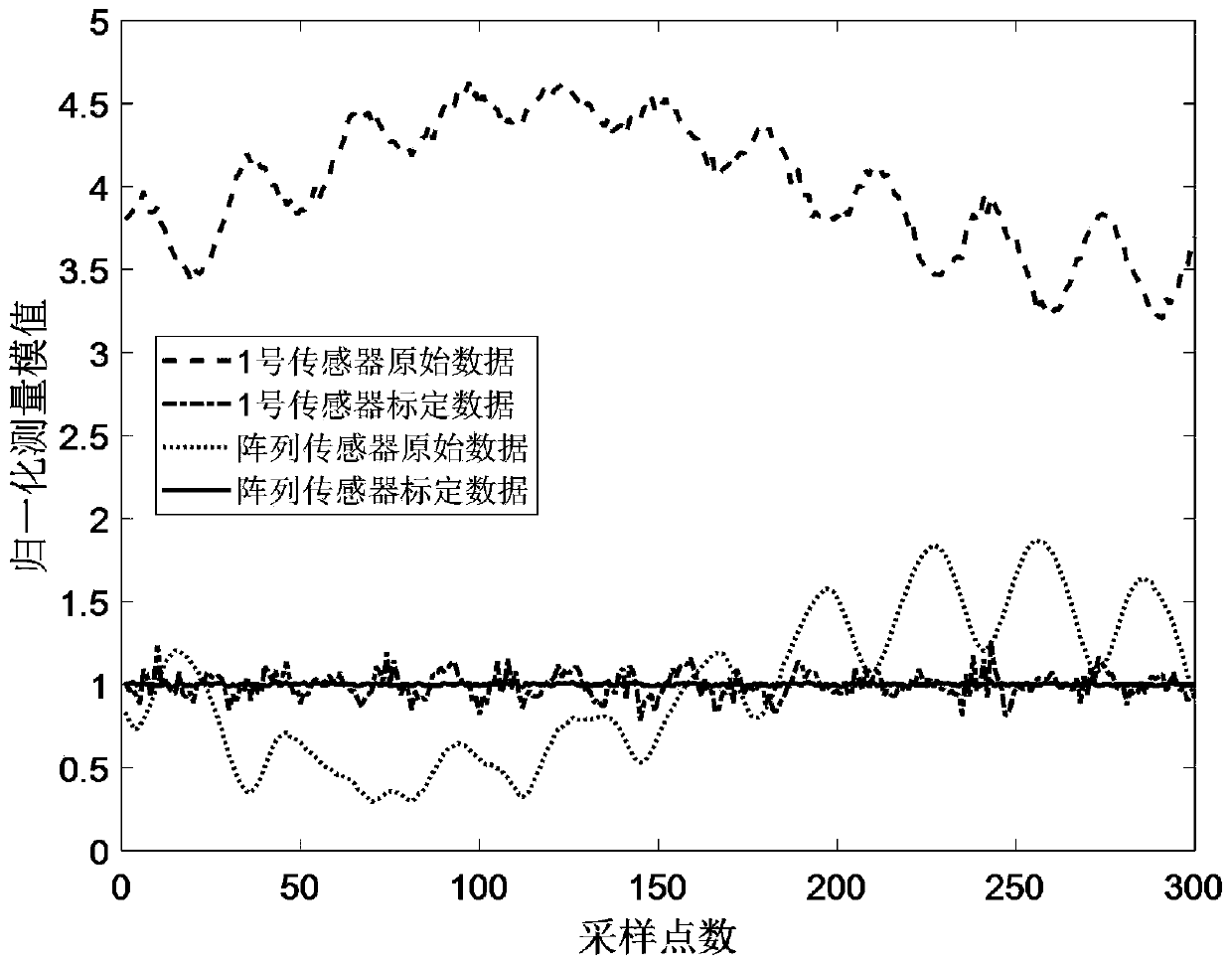

[0137] In this embodiment, a real-time calibration method for an arrayed MEMS magnetic sensor proposed by the present invention is simulated and verified by Matlab simulation software, thereby proving the accuracy of the calibration result of the arrayed MEMS magnetic sensor. The simulation hardware environment is Intel(R) Core(TM) T9600 CPU 2.80GHz, 4G RAM, Windows 7 operating system. Such as figure 2 Shown is the data acquisition curve of the array MEMS magnetic sensor, and the illustrated results show that the array MEMS magnetic sensor has a uniform result when measuring the magnetic field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com