Locomotive main transformer oil tank design method and strength simulation analysis method

A technology for main transformer and simulation analysis, applied in the field of locomotive main transformer oil tank design method and strength simulation analysis, can solve problems such as calculation result deviation, achieve the effect of ensuring accuracy and simplifying the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] -- Entity model creation

[0056] The three-dimensional solid model of the main transformer of a certain type of locomotive is established by using the CAD software Creo.

[0057] -- Finite element meshing

[0058] Import ANSYS Workbench finite element analysis software, after extracting the mid-plane of fuel tank body 1 and tank cover 5, use plate and shell elements to mesh the model. The block 3 and the seat plate 4 are meshed with solid elements. -- body 2 simulation

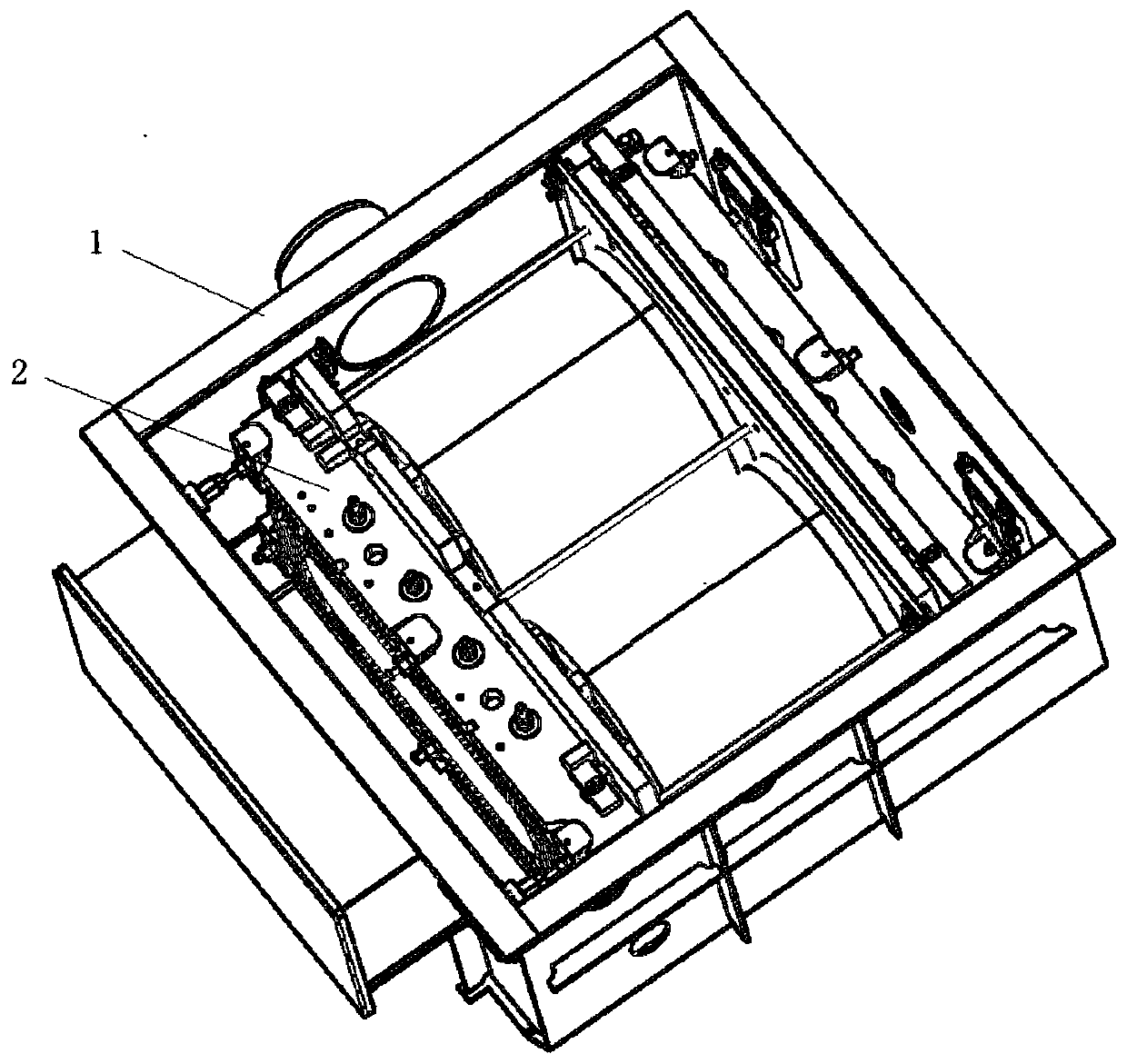

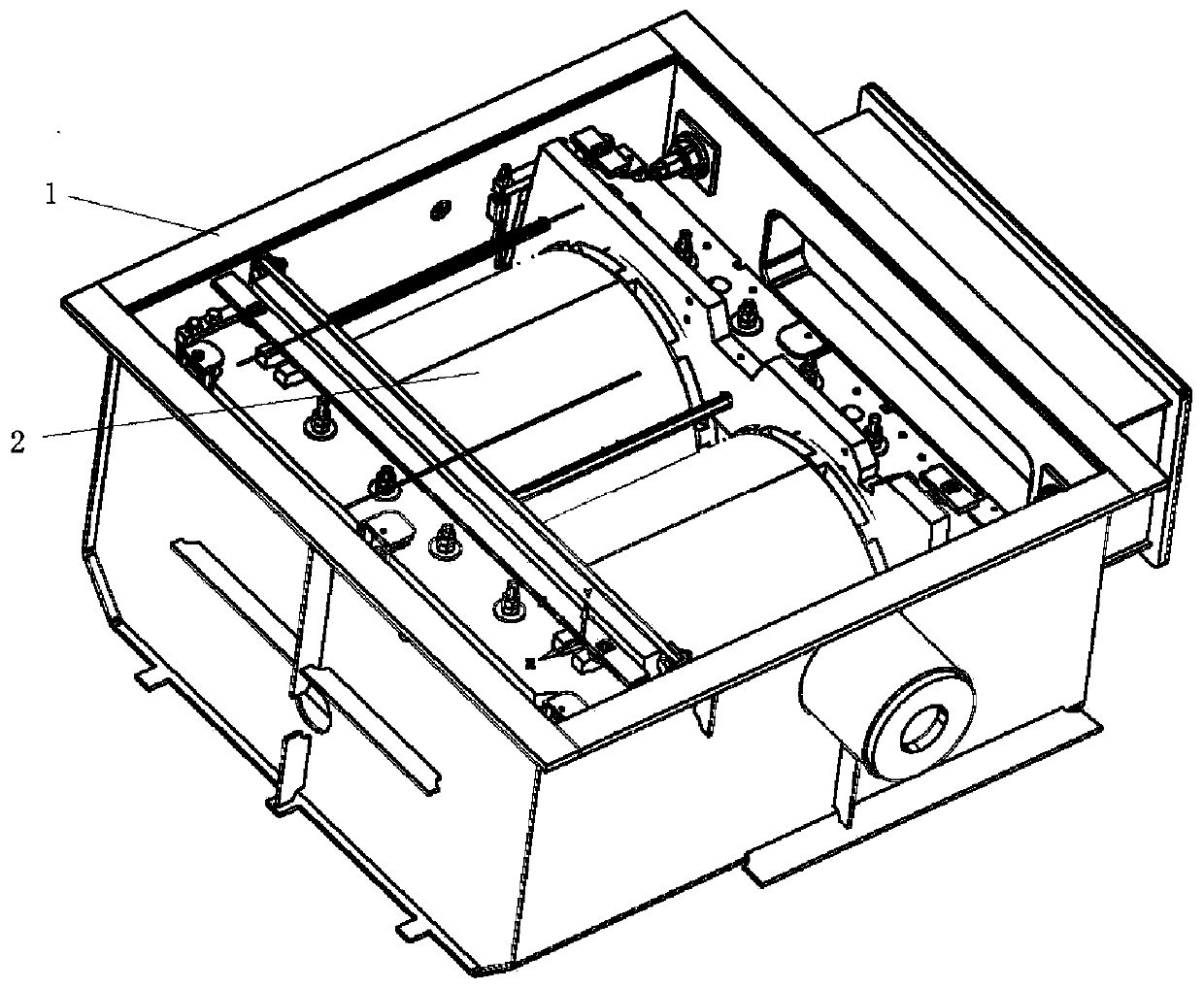

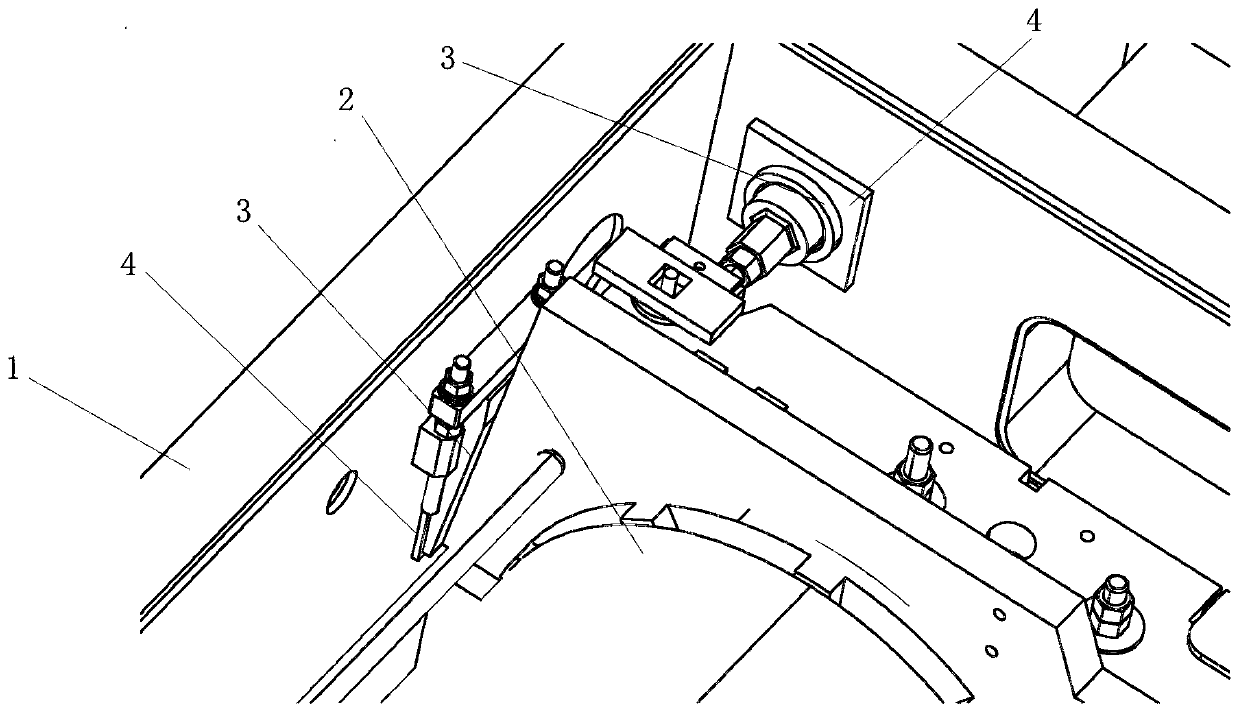

[0059] (1) The body 2 is simplified as a rigid body as a whole. For a schematic diagram of the connection relationship between the body 2 and the fuel tank body 1 and the tank cover 5, see Figure 1 to Figure 5. Among them, the seat plate 4 is welded on the box body 1 or the box cover 5; between the spacer 3 and the body 2, and between the spacer 3 and the seat plate 4 are frictional contact connections; the body 2 is fixed on the body through the spacer 3 Inside the fuel tank body 1; the tank co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com