Vacuum ball mill for preparation of aluminum powder for fireworks

A technology of vacuum balls and aluminum powder, which is applied in the field of vacuum ball mills, can solve the problems of affecting the ball milling effect, limited ball milling efficiency of aluminum raw materials, and long ball milling time, so as to improve ball milling quality, improve processing efficiency and production quality, and facilitate mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

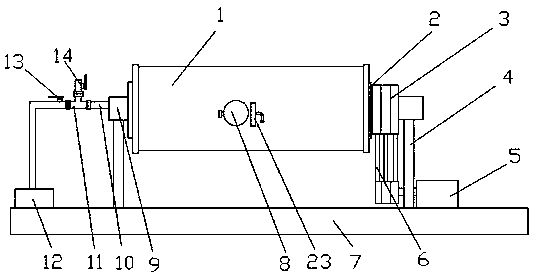

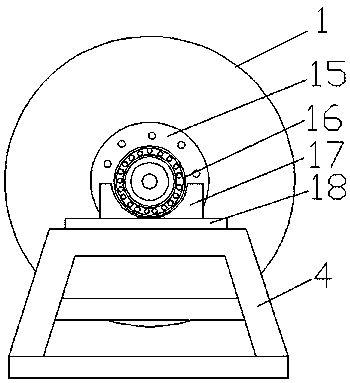

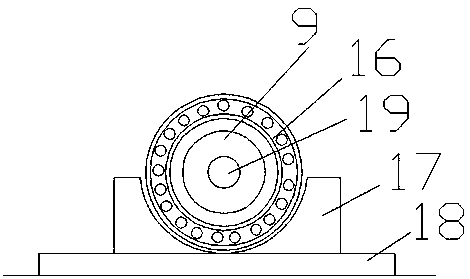

[0030] As shown in the figure, a vacuum ball mill for preparing firework aluminum powder includes a barrel-shaped mill body 1, a mounting base 4 and a drive motor 5. The two ends of the mill body 1 are respectively provided with concentric shafts 9, and the concentric shafts 9 pass through bearings. 16 is installed and fixed on the mounting seat 4, one end of the grinding body 1 is provided with a belt pulley 3, the belt pulley 3 is connected to the driving motor 5 through a belt 6, the concentric shaft 9 is provided with a through hole 19 communicating with the inside of the grinding body 1, and the concentric shaft 9 includes The left concentric shaft 9 and the right concentric shaft 9 are provided with a through hole 19 corresponding to the concentric shaft 9. The through hole 19 includes a left through hole 19 and a right through hole 19, an observation window is set in the left through hole 19, and the right through hole 19 passes through the pipe 10. Connect with the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com