Rubber extruding machine head with vacuumizing function

A technology of extruding rubber and vacuuming, which is applied in the direction of conductor/cable insulation and coating, which can solve the problems of insufficient tightness of cable sheath and wire core coating, failure to meet the requirements of cable use, and affecting the use effect of cables, etc. , to prevent and reduce the air from entering the cable sheath, simple structure, tight covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

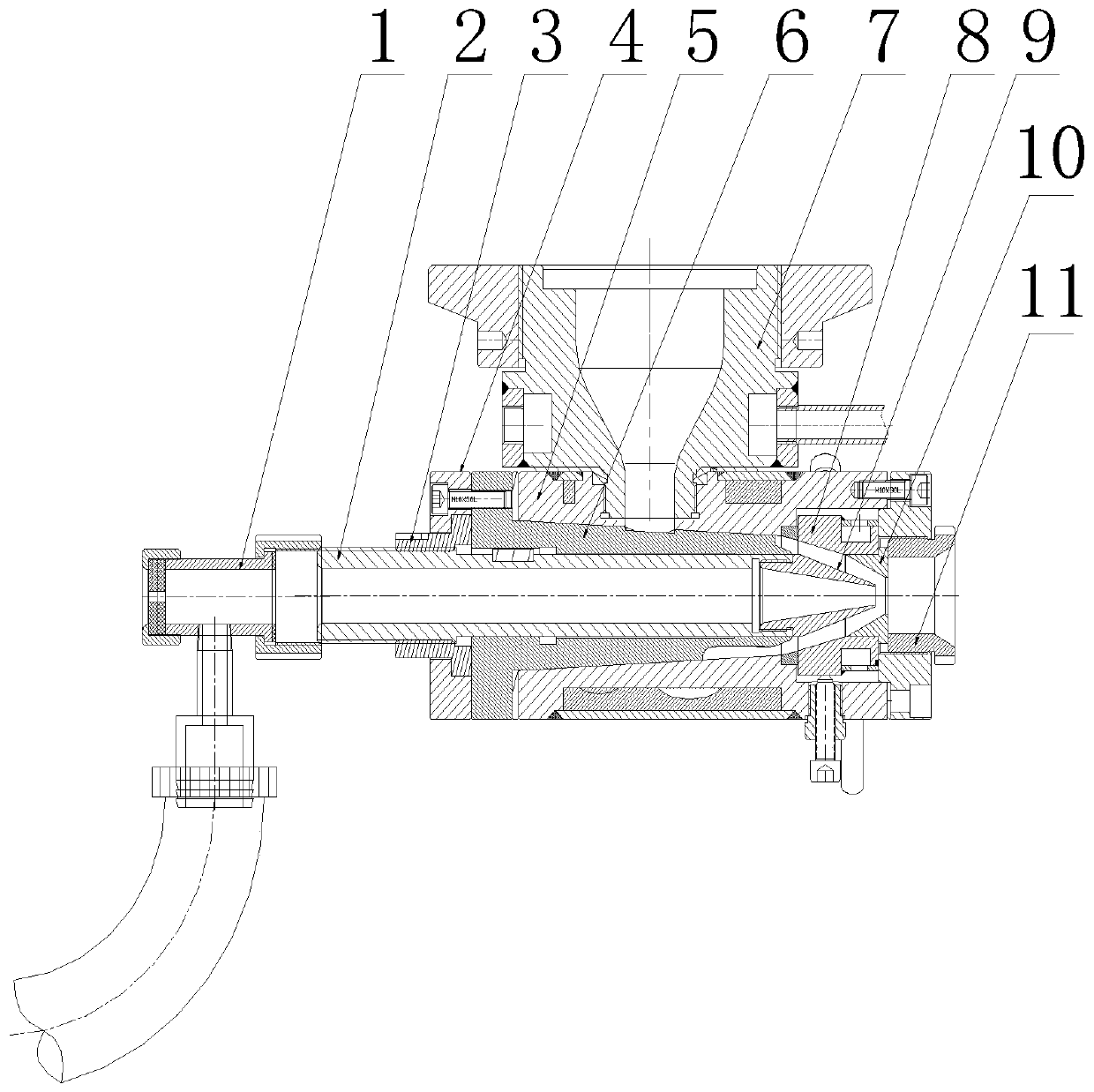

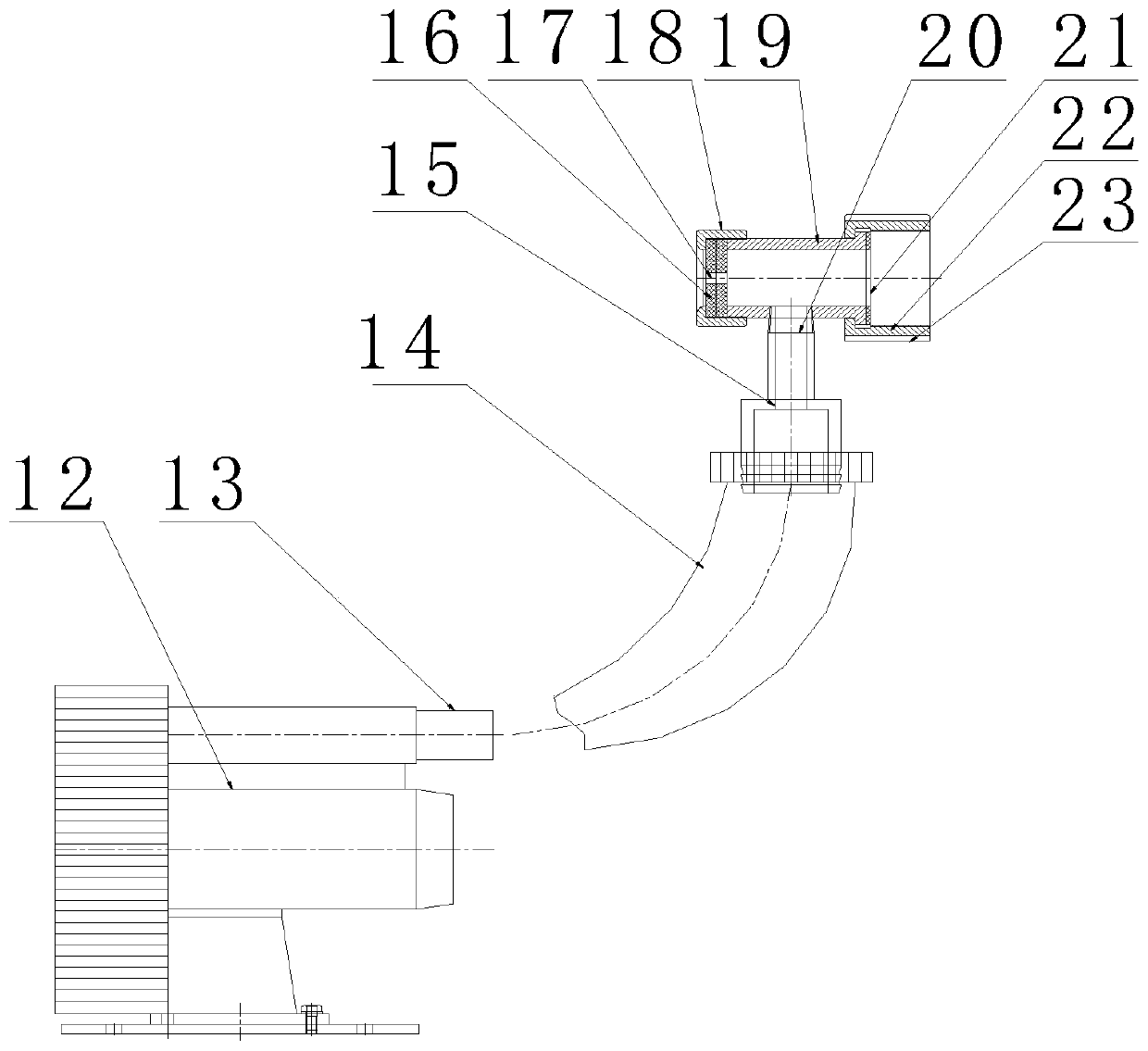

[0018] A head of a rubber extruder with a vacuum function, comprising a machine neck 7, a head body 5, a fluid divider 6, a line passing pipe 2, a connecting sleeve 11, an adjusting sleeve 3, an outlet mold sleeve 10, a mold sleeve base 8, Outlet core 9, gland 4, also includes a vacuum device 1. The machine neck is screwed on the upper part of the machine head body, the fluid distribution and the line pipe are coaxially installed inside the machine head body, the connecting sleeve is installed at the front end of the machine head body, and the adjusting sleeve and gland are installed at the rear end of the machine head body. The front end of the wire-passing pipe in the body of the machine head is fixedly equipped with an outlet mold core, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com