Cement concrete pavement grooving equipment for standardized construction of highway engineering

A technology of cement concrete and engineering, which is applied in the field of cement concrete pavement groove equipment for standardized construction of highway engineering. It can solve problems such as improper adjustment, lack of dust collection function, and impact on health, so as to increase applicability and prevent dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

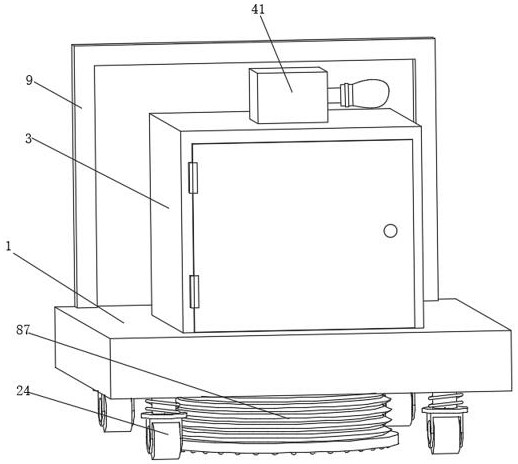

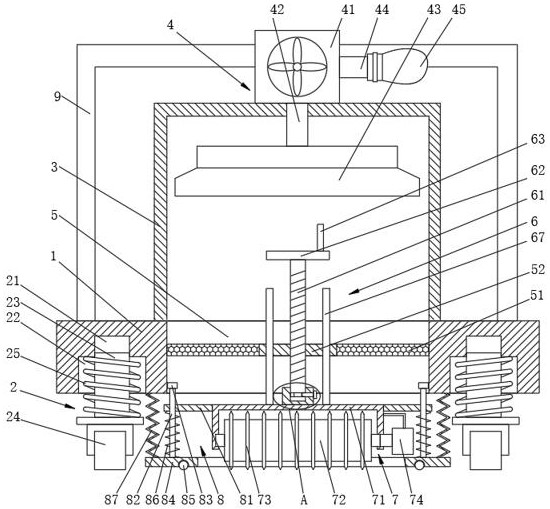

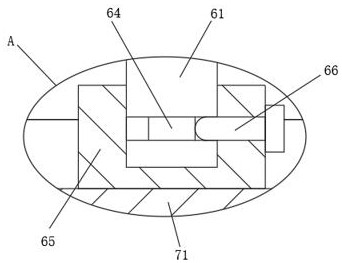

[0026] A kind of highway engineering standardization construction cement concrete pavement slotting equipment, including base 1, mobile mechanism 2, box 3, exhaust device 4, channel 5, depth adjustment mechanism 6, slotting mechanism 7, diversion mechanism 8 and push handle 9, the bottom of the base 1 is provided with a mobile mechanism 2, the base 1 is fixed to the upper end of the box 3, the top of the box 3 is provided with an exhaust device 4, the middle of the base 1 is opened with a channel 5, the channel 5 is fixed connected to the filter plate 51, The central fixed connection of the filter plate 51 is connected to the center plate 52, the center plate 52 is provided with a depth adjustment mechanism 6, the bottom of the depth adjustment mechanism 6 is provided with a slot mechanism 7, the slot mechanism 7 is provided with a diversion mechanism 8, the base 1 is welded with a push handle 9.

[0027] Wherein, the moving mechanism 2 includes a movable groove 21, a storage groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com