Two-dimensional printing nozzle test charts

A technology for testing patterns and nozzles, which is applied in printing, printing devices, transfer materials, etc., and can solve problems such as the inability to obtain the quality of test pattern printing nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

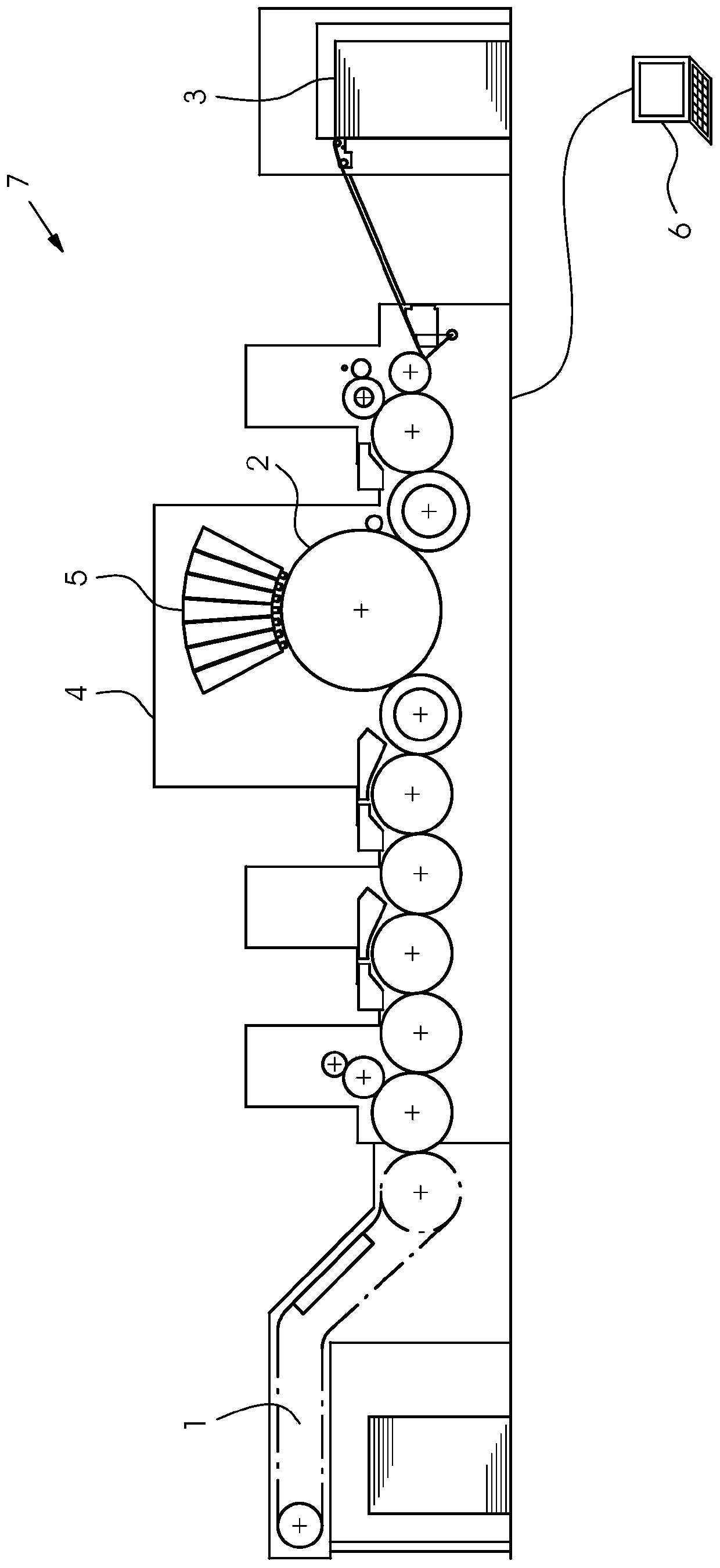

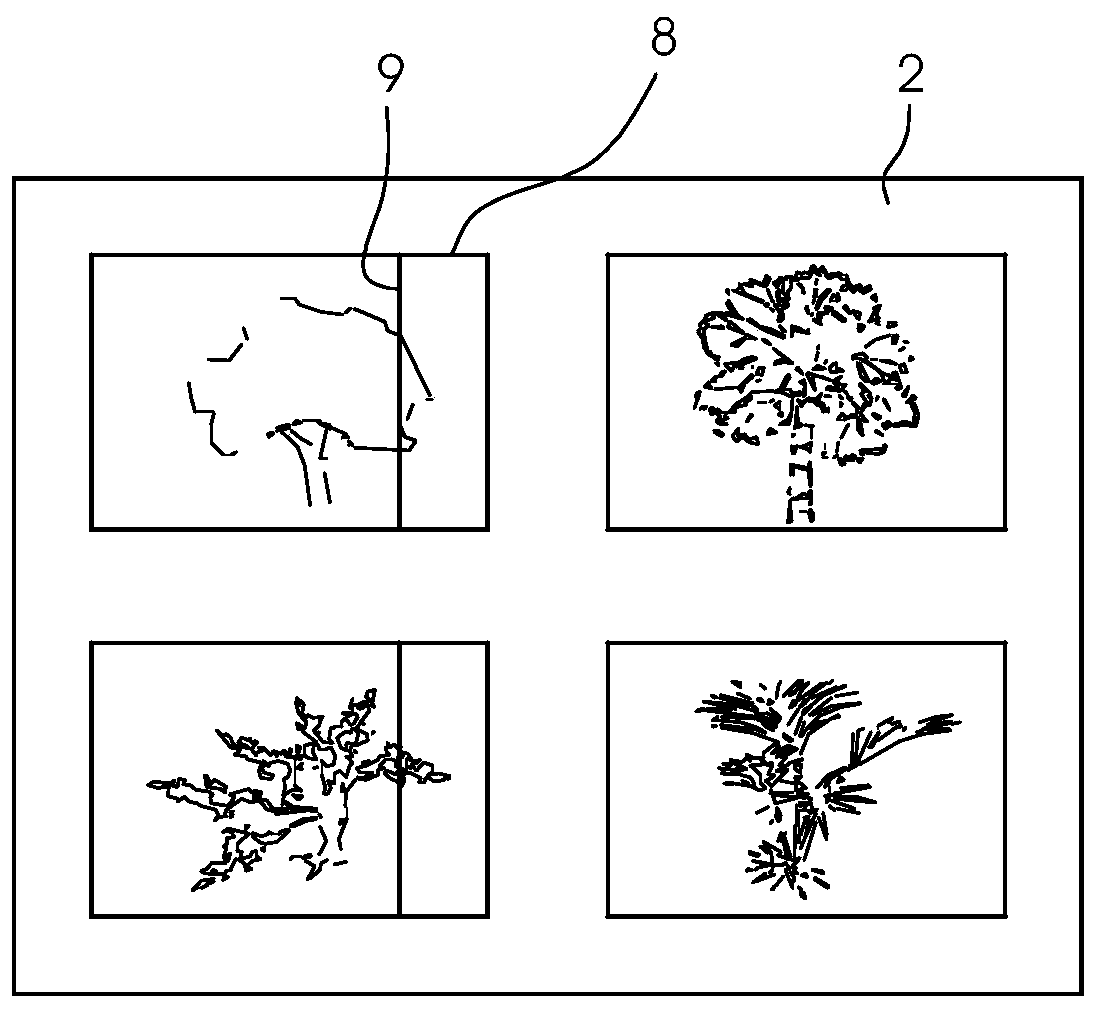

[0026] A preferred field of application for implementing the variant is the inkjet printer 7 . figure 1 An example of the basic structure of a machine 7 of this type is shown, comprising a feeder 1 for feeding a printing substrate 2 into a printing mechanism 4 where the printing substrate 2 is printed by a printing head 5 up to a take-up. Feeder 3. This is a sheet inkjet printer 7 controlled by a control computer 6 . As already described, it may occur that individual print nozzles in the print heads 5 in the printing unit 4 fail during operation of the printing press 7 . The consequence is white lines 9, or distorted color values in the case of multicolor printing. figure 2 An example of such a white line 9 is shown in the printed image 8 .

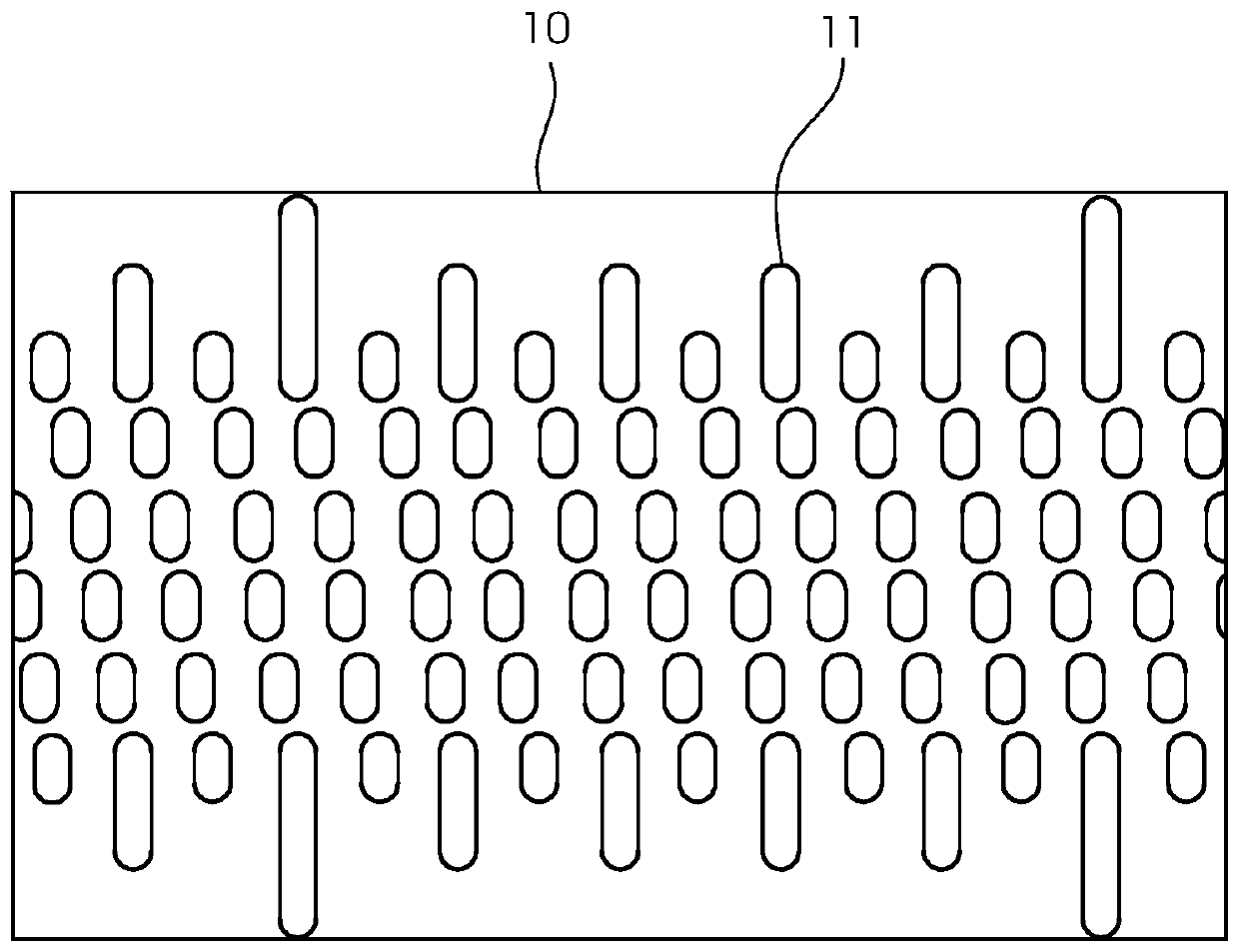

[0027] The object of the method according to the invention is to apply a test pattern 12 for detecting characteristic values of the printing nozzles, which test pattern 12 provides information both in the transverse direction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com