Method for processing rectangular micropore mould of diamond with laser

A micro-hole mold and laser processing technology, applied in the field of mold processing, can solve the problems of difficult to ensure tolerance size, difficult to process small hole electrodes, consumption of precious metal materials, etc., to achieve high hole shape dimensional accuracy, shorten production cycle, and hole shape good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for laser machining diamond rectangular micro-hole mold provided in this embodiment comprises the following steps:

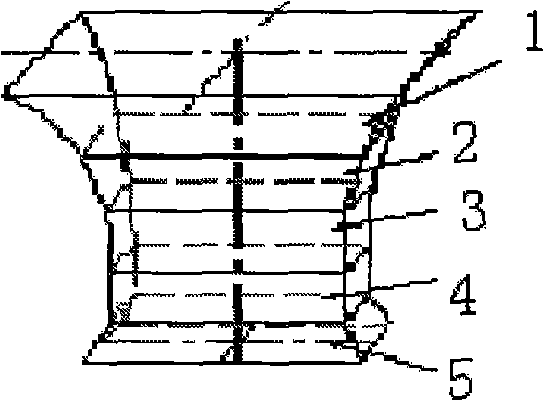

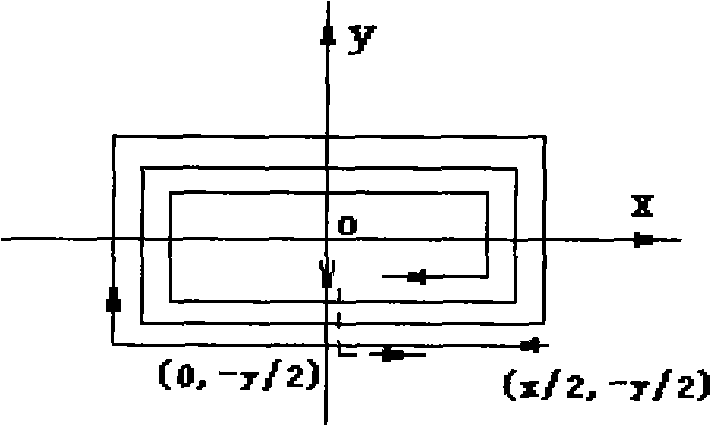

[0027] (1) Design the hole shape of the die hole so that the longitudinal section in the length direction of the die hole--Y direction and the width direction--X direction has a wire introduction area 1, a lubrication area 2, an extrusion deformation area 3, a fixed Path area 4 and lead-out area 5 (such as figure 1 shown);

[0028] (2) According to the shape of the hole, design and compile the computer operation program;

[0029] (3) The three-dimensional motion platform is controlled by a computer program for three-dimensional motion in space; the X-axis and Y-axis strokes are each 50 mm, and a grating displacement digital measurement system is installed with a resolution of less than 0.5 microns for closed-loop monitoring and control of displacement. Z The displacement is controlled by the motor;

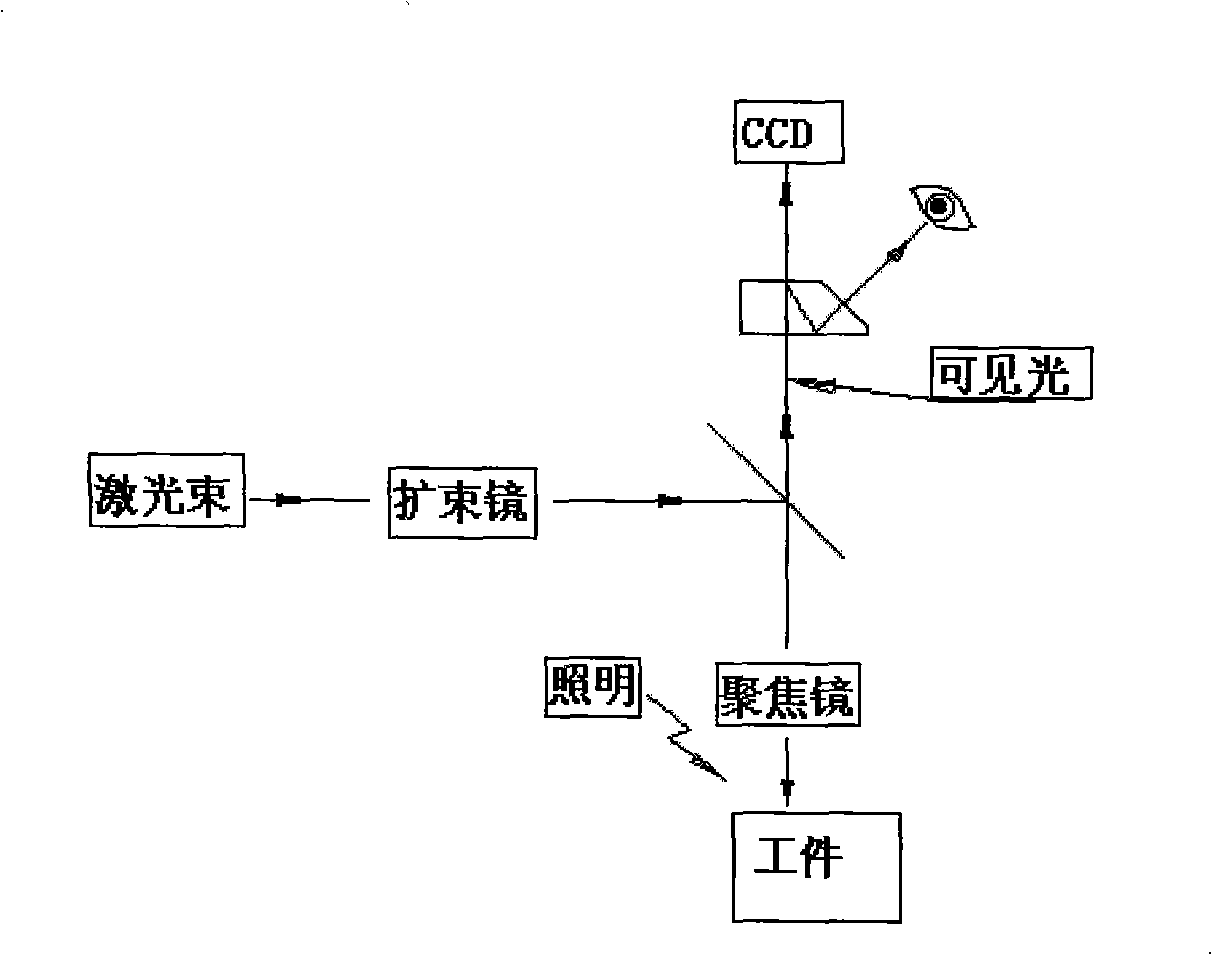

[0030] (4) Using light-emitting diode pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com