Method for representing single-crystal Ni-base alloy creep resistance

A technology for creep properties and base alloys, which is applied in the field of research on the mechanical properties of superalloys, and can solve the problems that there is no simple and effective method for describing the creep curve of single crystal Ni-based alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

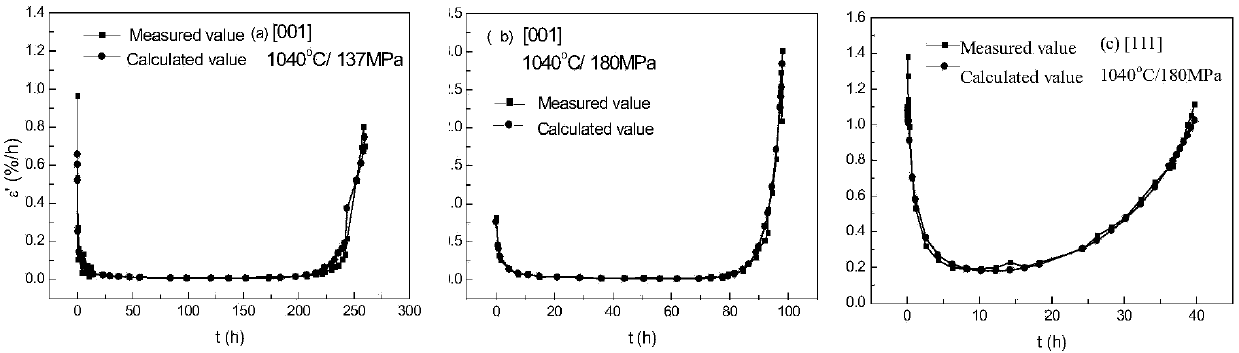

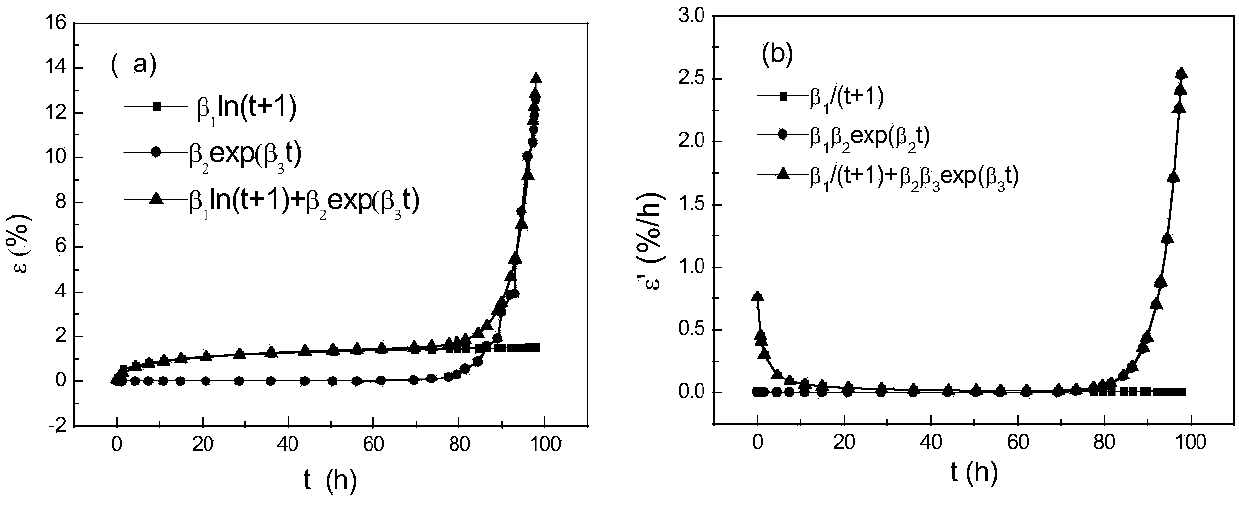

[0108] Example 1. Characterization of the creep properties of DD3 single crystal Ni-based alloys with different orientations

[0109] DD3 single crystal Ni-based alloy is a cost-effective single-crystal Ni-based alloy independently developed by my country. As shown in Table 1, the creep curve model ε=β is used 0 +β 1 ln(t+1)+β 2 exp(β 3 t) Obtain [001] orientation DD3 single crystal Ni-based alloy at 1040°C / 137MPa, 1040°C / 180MPa and [111] orientation alloy at 1040°C / 137MPa, 1070°C / 137MPa, 1040°C / 180MPa and [011] orientation alloy Creep parameter β at 1040℃ / 137MPa i (i=0,1,2,3) value, calculated creep rate, measured creep rate, maximum strain and creep life. Among them, the creep fitting curves of [001] orientation alloy at 1040°C / 137MPa, 1040°C / 180MPa and [111] orientation alloy at 1040°C / 180MPa are as follows figure 1 As shown, the comparison between the corresponding calculated creep rate curve and the measured creep rate curve is as follows figure 2 shown. visible:...

example 2

[0118] Example 2. Characterization of creep properties of a [001] orientation rhenium-free single crystal Ni-based alloy

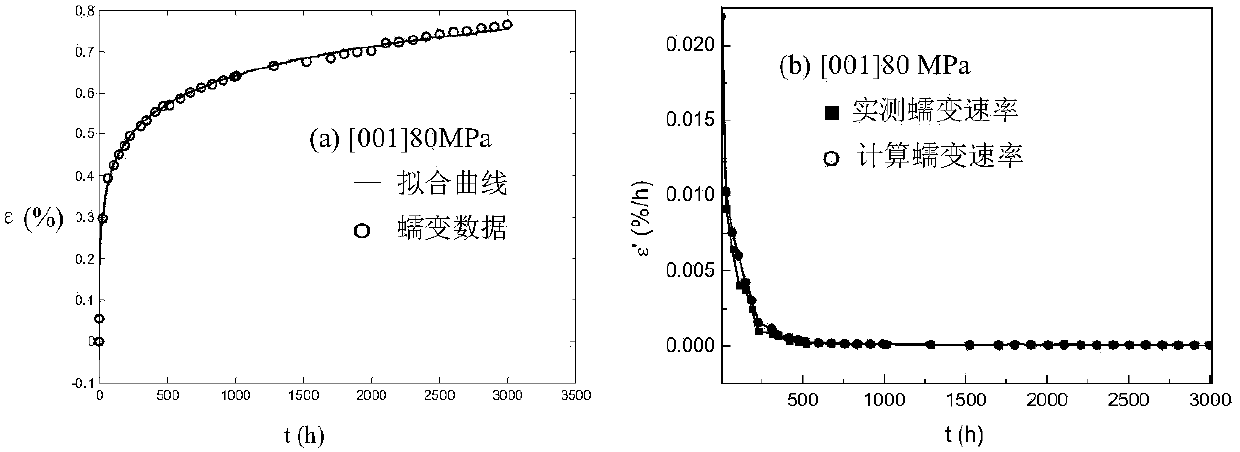

[0119] Using this creep curve model, the parameters of the creep curve of a [001]-oriented rhenium-free single crystal Ni-based alloy at 1040°C / 80MPa for 3000h are obtained: β 0 = 0.0615, β 1 = 0.1017, β 2 =0.0206,β 3 =-0.0091. ie beta 3 -5 % / h; at 3100h, the creep strain is only 0.75%, and the creep rate is only 3.28065×10 -5 % / h. The calculation results show that the strains at the early stage of creep and at the late stage of creep respectively meet: ε=0.1017ln(t+1)-0.0206exp(-0.0091t) and ε=0.1017ln(t+1); due to β 2 and |β 3 |The value is very small, therefore, the strain is basically dominated by ε=0.1017ln(t+1), and the creep rate variation trend is ε'=0.1017 / (t+1), β 1 Basically represents the creep performance of the alloy.

[0120] like Figure 4 (a) and (b) respectively show the creep fitting curve of the alloy creeping at 1040℃ / 80MPa f...

example 3

[0121] Example 3. Characterization of creep properties of a [001] orientation containing 4.5% Re single crystal Ni-based alloy under high temperature medium stress and medium temperature high stress conditions

[0122] The single crystal Ni base alloy containing 4.5% Re is a representative single crystal Ni base alloy. Table 2 shows the strain and creep life of the alloy at 1100oC / 137MPa and 830oC / 820MPa, as well as the creep parameter values obtained by using this creep curve model, the calculated creep rate and its comparison with the measured creep rate. The corresponding creep fitting curve and creep rate curve are as follows: Figure 5 , 6 shown. visible:

[0123] (1) This model also describes the whole creep process of the alloy relatively completely, and the calculated creep rate is in good agreement with the measured creep rate, indicating that this model is still suitable for expressing the creep of single crystal Ni-based alloy containing 4.5% Re curve.

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com