Exciting load loading method for water-jet propeller

A water jet propulsion, water jet propulsion technology, applied to ship components, ships, transportation and packaging, etc., can solve problems such as excitation loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

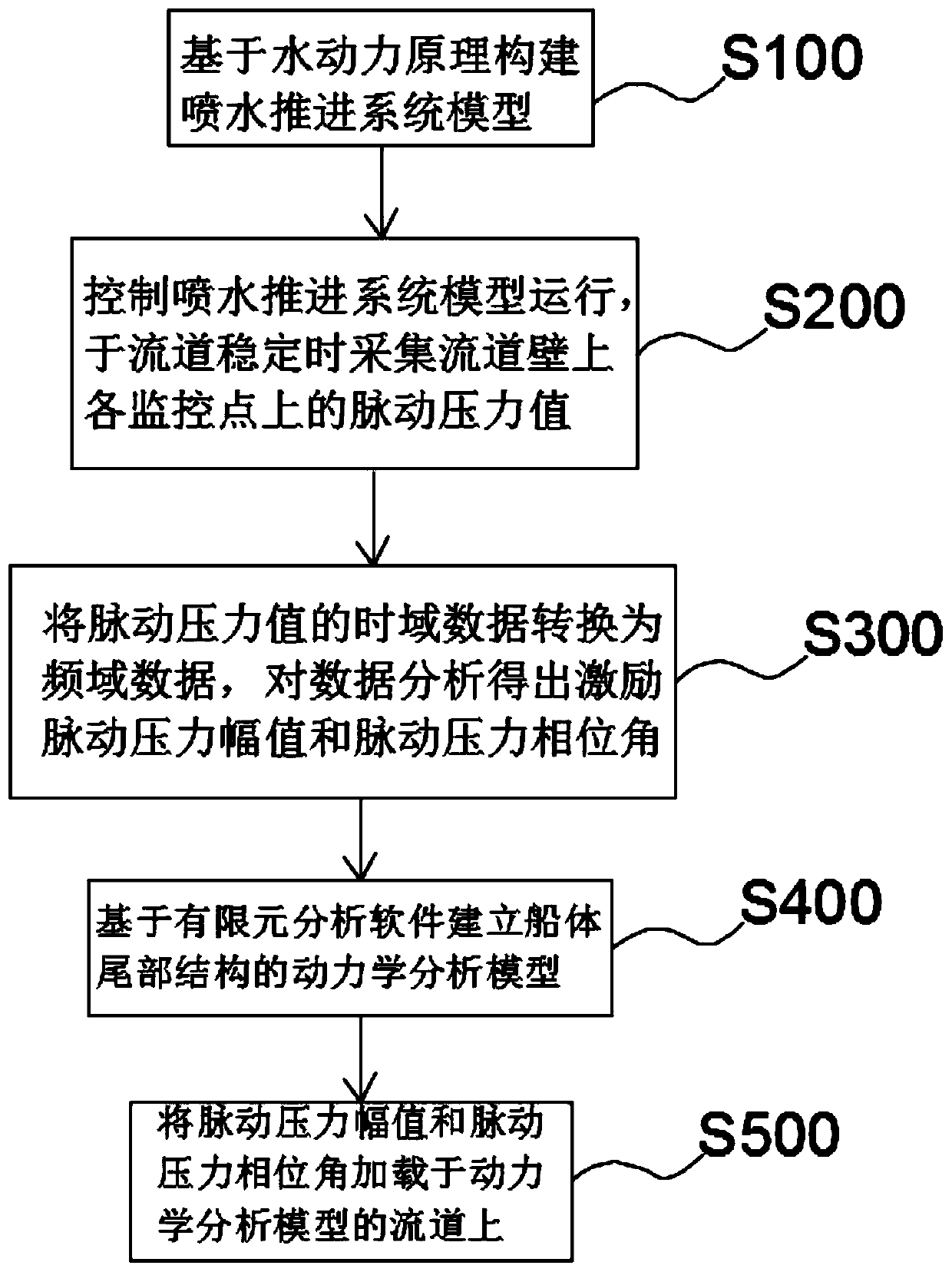

Method used

Image

Examples

Embodiment approach

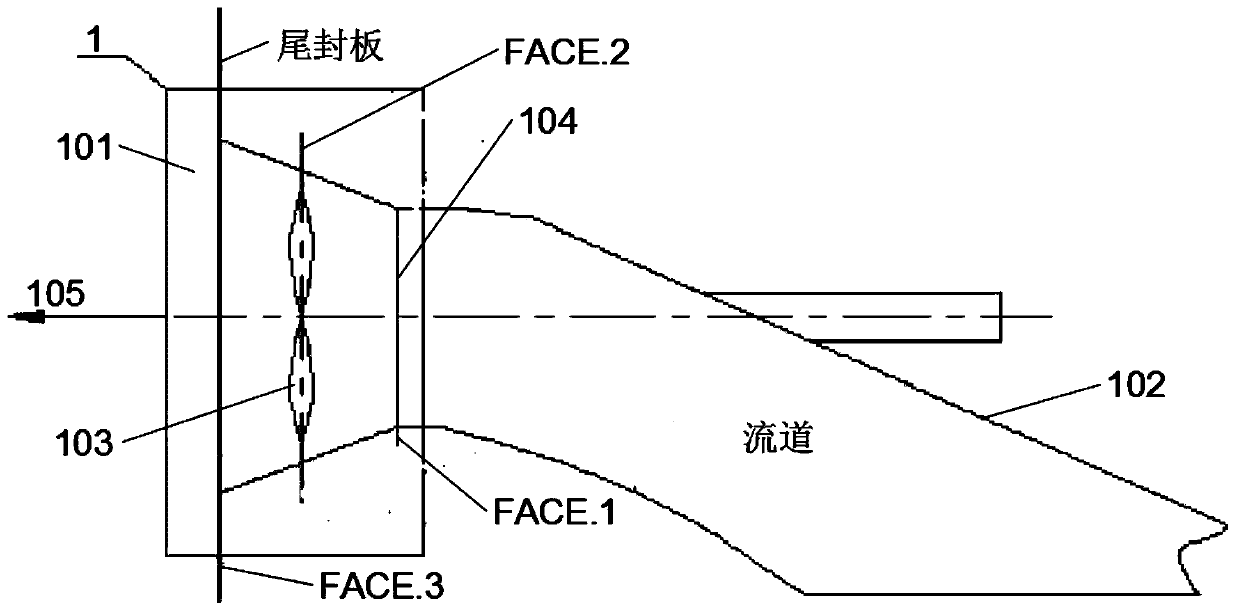

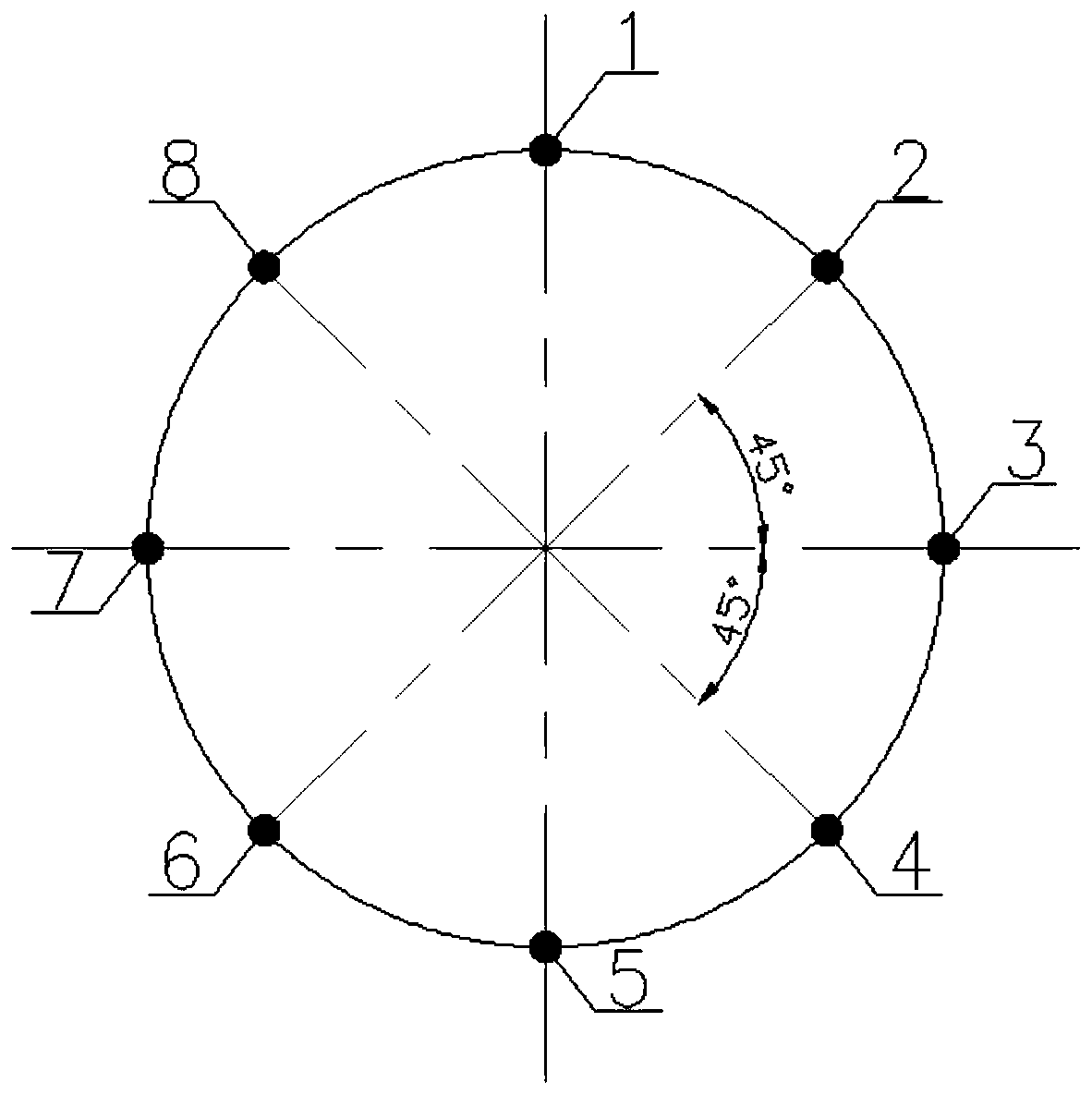

[0048] As a preferred embodiment of the present invention, the monitoring points include the first pressure monitoring group, the second pressure monitoring group and the third pressure monitoring group, and the first pressure monitoring group, the second pressure monitoring group and the third pressure monitoring group are all set Several pressure monitoring points;

[0049] The first pressure monitoring group is arranged on the water inlet section of the flow channel, the second pressure monitoring group is arranged on the impeller section, and the third pressure monitoring group is arranged on the water outlet section of the flow channel. Specifically, 8 pressure monitoring points are uniformly set in each section, and there are 24 monitoring points in three sections.

[0050] Through Fourier transform, the time-domain results of the pulsating pressure at the 24 monitoring points obtained by the above-mentioned measurement and acquisition are converted into frequency-domain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com