Fixed-length forming matrix warp let-off device

A matrix-type, let-off technology, applied in the direction of textiles, textiles, papermaking, looms, etc., can solve problems such as unclear openings, uneven warp tension, and easy damage to yarns, and achieve force balance, reduce friction, and The effect of increasing the opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

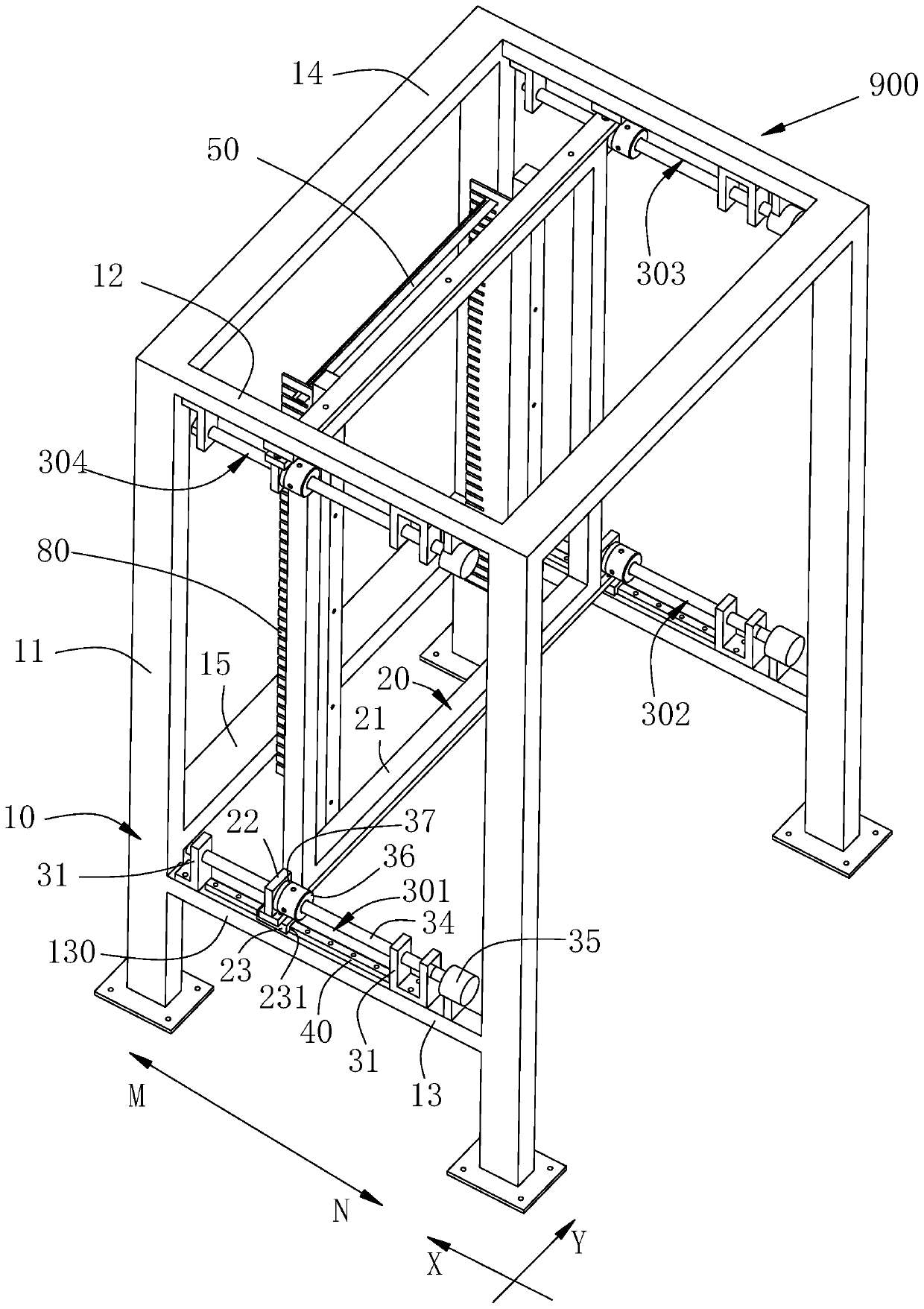

[0029] refer to figure 1 , in the figure 1 Among them, the direction of the arrow X indicates the width direction of the equipment, which corresponds to the warp direction of the fabric, the arrow Y indicates the length direction of the equipment, which corresponds to the weft direction of the fabric, and the direction of the arrow N is the drawing direction of the warp yarn, The side of the device facing the drawing direction of the warp yarn is called the weaving side, and the side opposite to the weaving side is called the non-woven side, that is, the direction of the arrow M is the non-woven side.

[0030] A fixed-length forming matrix let-off device 900, which includes a frame 10, the frame 10 includes four columns 11 arranged in a rectangular shape, and an upper beam is arranged between every two columns arranged along the width direction X 12 and the lower beam 13, wherein the upper beam 12 is positioned between the tops of the two columns, and the lower beam 13 is pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com