A pipeline driving robot for in-situ detection of loess

An in-situ detection and robot technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of pipeline robots that cannot be positioned accurately and robot design is complicated, and achieve the effect of simple structure, good adaptability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

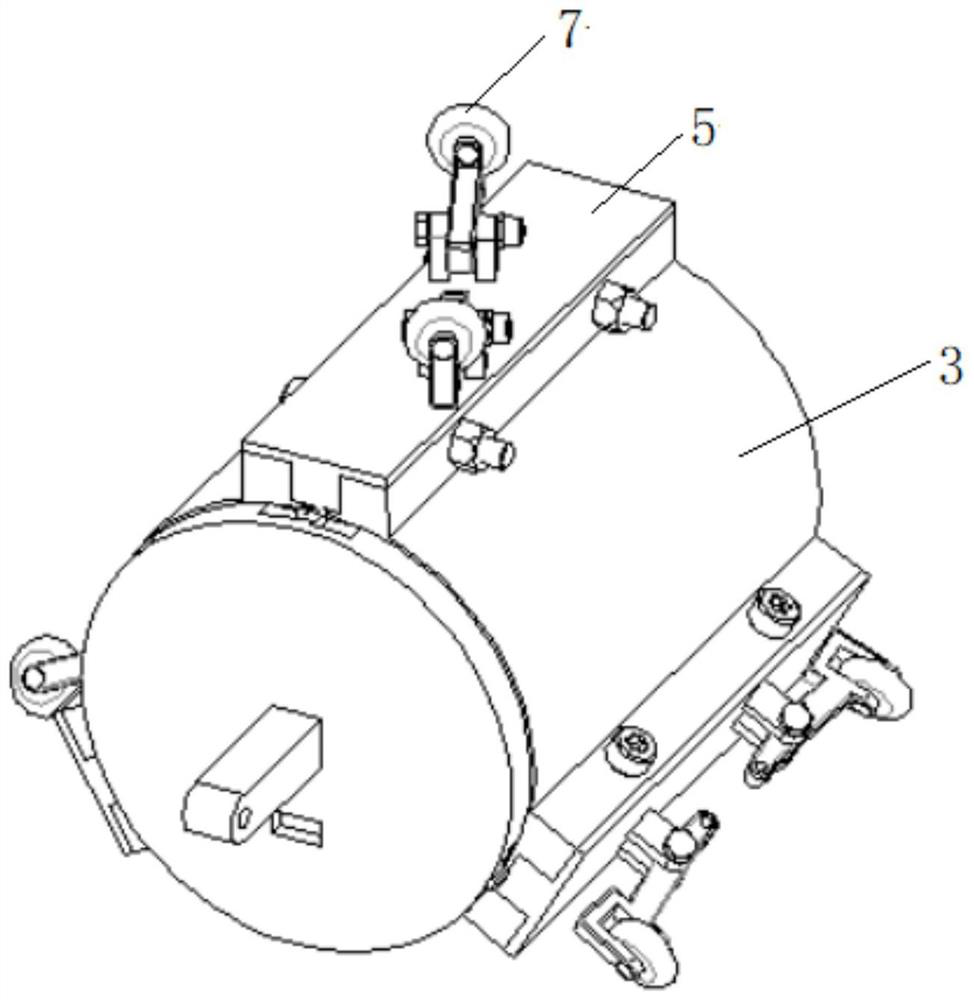

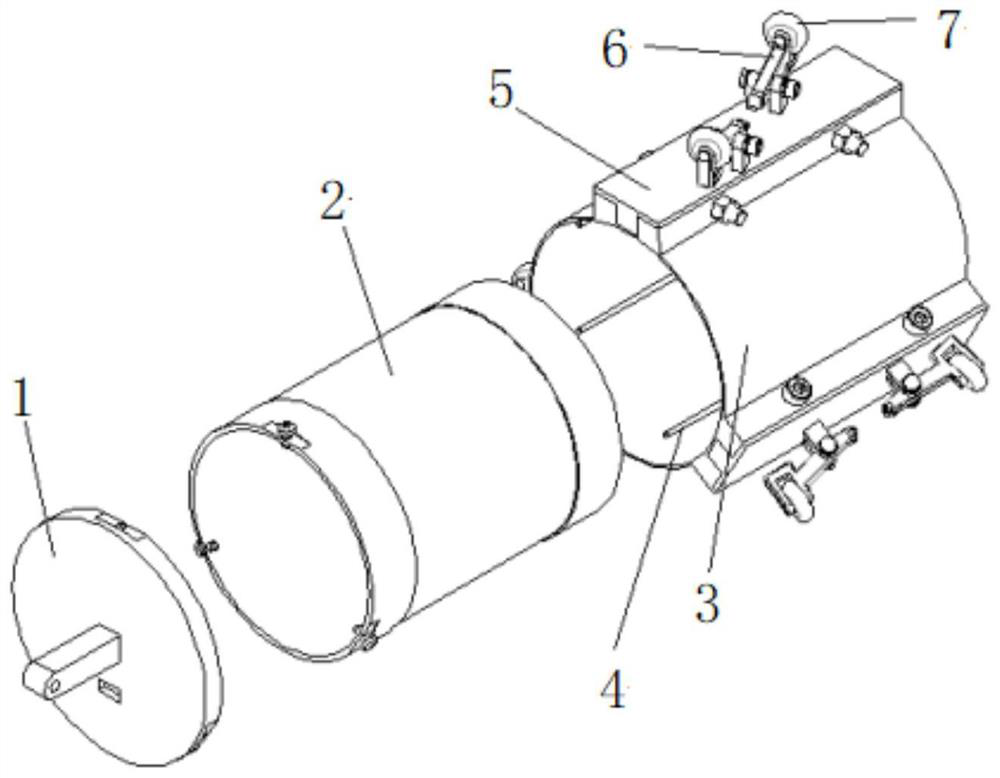

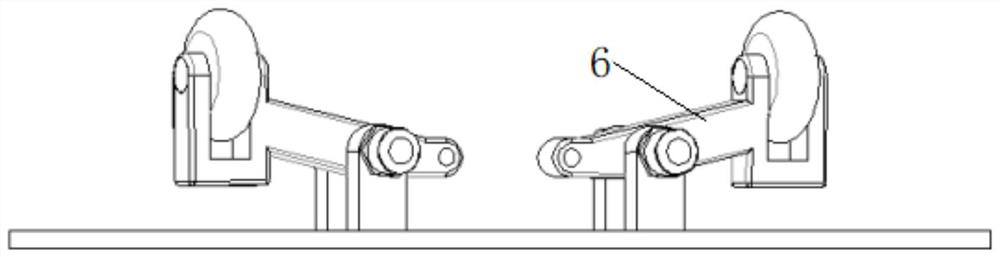

[0027] see Figure 1-5 , this embodiment provides a loess in-situ detection pipeline driving robot, and the necessary structures of the wheeled pipeline robot are a rotating body and a holding body. Through the structural design, this scheme designs the rotating body and the holding body on one structure, so that the inner ring becomes the retainer, the outer ring becomes the rotating body, and the output shaft of the motor is fixedly connected to the outer ring to drive the outer ring to rotate, omitting the universal joint. Connection, which will greatly shorten the length of the robot, because it mainly plays a driving role, so it is called a pipe-driven robot. details as follows:

[0028] A pipeline-driven robot for in-situ detection of loess, comprising an outer ring rotating body 3 and an inner ring holding body 2, the inner ring holding body 2 is sleeved in the outer ring rotating body 3 and is rollingly connected with the outer ring rotating body 3, the outer ring rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com