A magnetic field generator and its manufacturing method

A magnetic field generator, square technology, applied in the manufacture of inductors/transformers/magnets, magnets, electromagnets, etc., can solve the problem of difficult to obtain high-intensity uniform magnetic field generators, unsatisfactory magnetic field uniformity, and limited solenoid length. and other problems, to achieve the effect of improving calculation and design efficiency, simple and reliable production method, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the present invention is described in further detail:

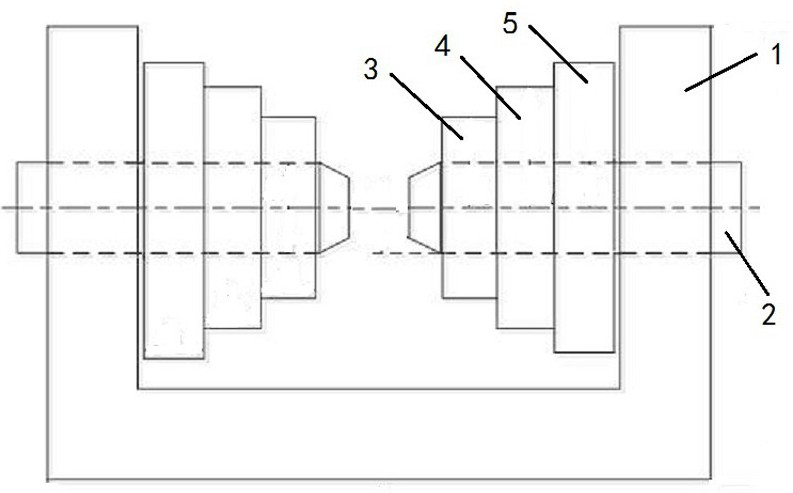

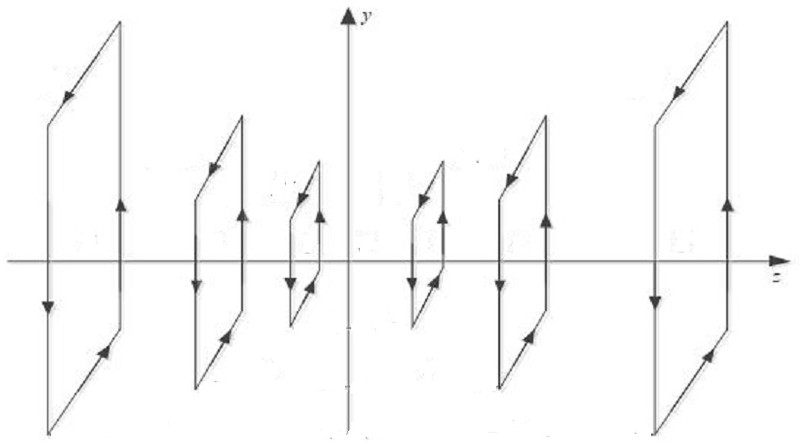

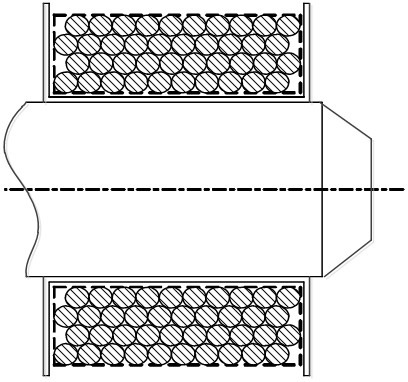

[0037] Such as figure 1As shown, a magnetic field generating device includes a U-shaped frame 1, an armature 2 and three sets of square Helmholtz coils. Two armatures 2 are symmetrically arranged on both sides of the U-shaped frame 1 and can move relative to the U-shaped frame. The inner end of 2 is a tapered quadrangular prism magnetic head, and the armature 1 is wound with three sets of square Helmholtz coils from inside to outside. The three sets of square Helmholtz coils are: primary square Helmholtz coil 3, secondary Square Helmholtz coil 4 and three-stage square Helmholtz coil 5 . Among them, the primary square Helmholtz coil 3, the secondary square Helmholtz coil 4 and the tertiary square Helmholtz coil 5 are two groups, and the two groups of primary square Helmholtz coil 3, secondary Square Helmholtz coils 4 and tertiary square Helmholtz coils 5 are symmetrically distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com